Product Introduction:

Introduction to Additive Liquid Silicone: Additive silicone is also known as two component additive silicone. platinum cure silicone mold It consists of two parts: component A is silicone, and component B is a curing agent; Mix the two components in a 1:1 ratio. This product is a semi transparent oily liquid, which becomes a resilient material with good toughness after vulcanization.

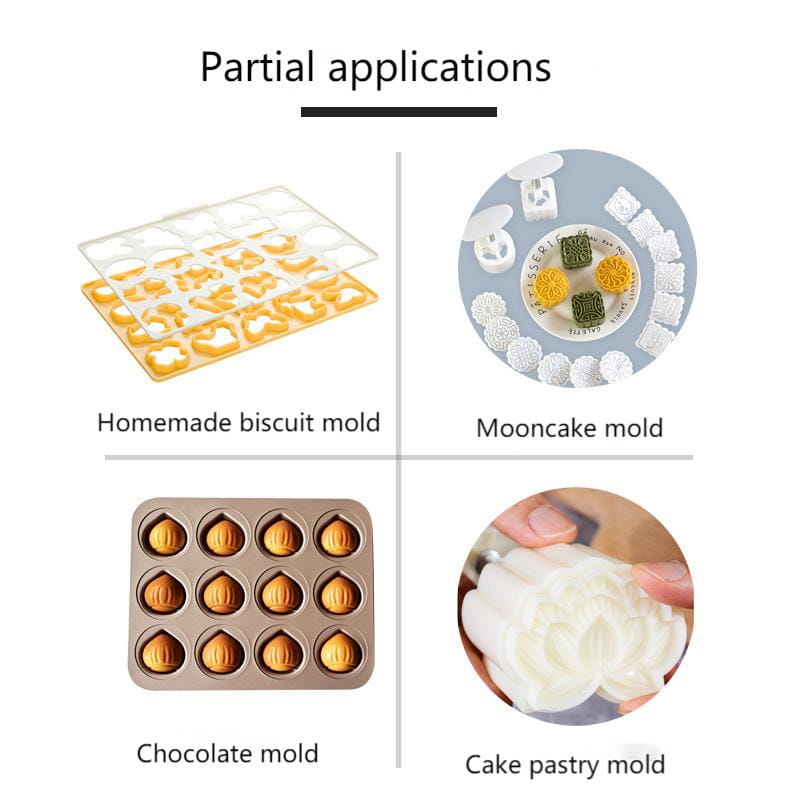

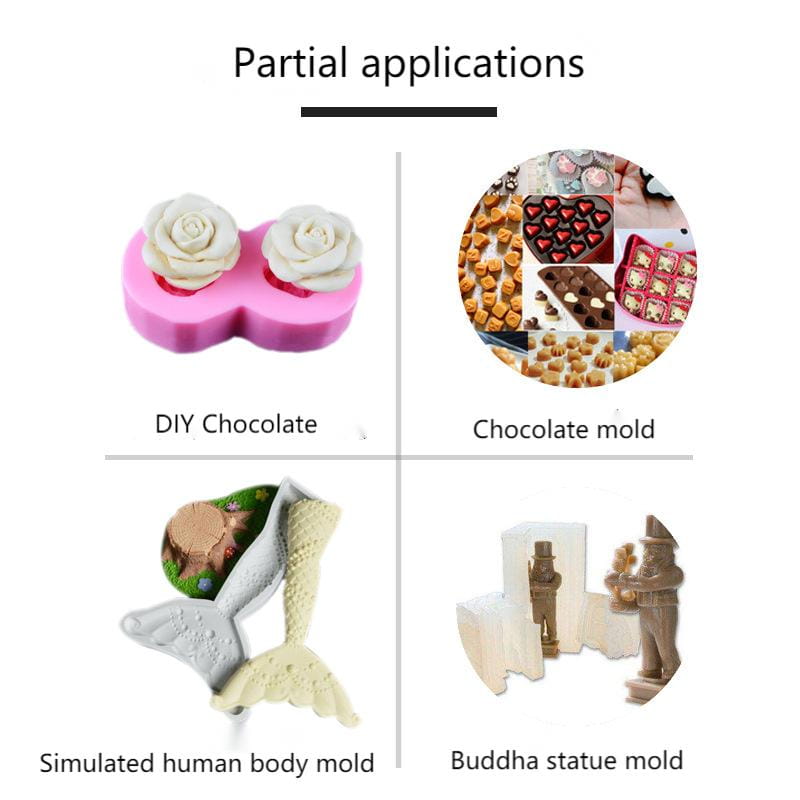

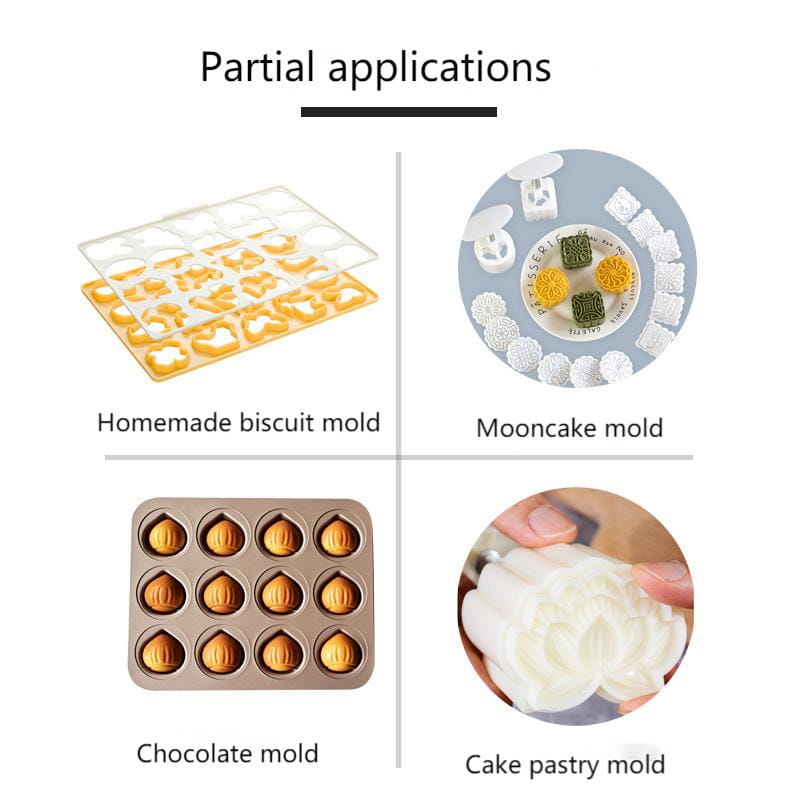

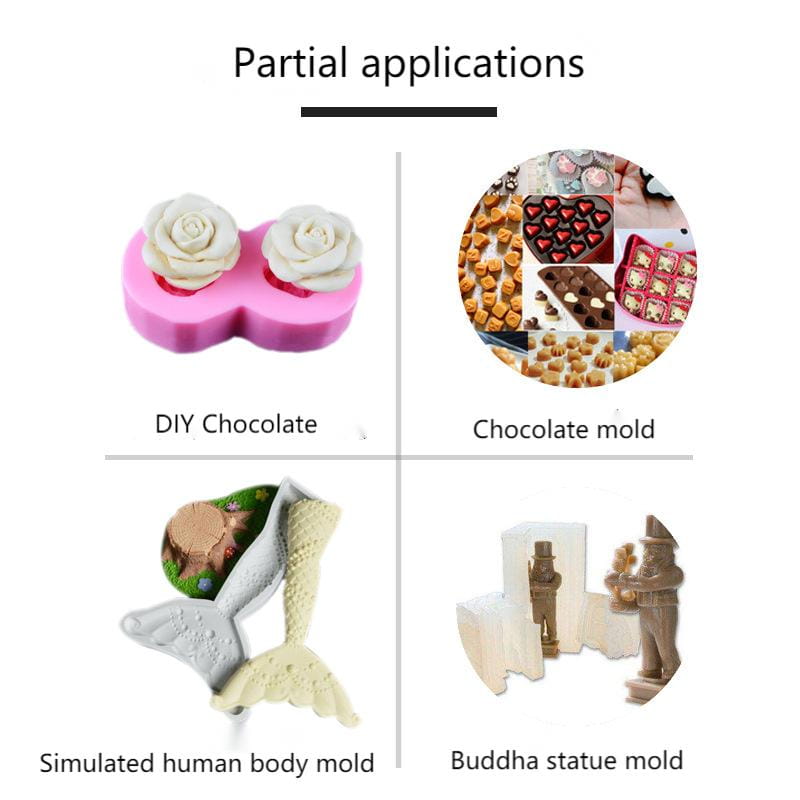

Application:

Mainly used for human appearance, sexual organs, chest pads, shoulder pads, patches, anti slip pads, adult products, and can also be used for simulating human facial molds. Silicone is mainly used for human facial and limb modeling, with unchanged shape, variable shape, and soft touch. Due to its food grade nature, it can be used for making food molds. Food grade liquid silicone is mainly used for food molds, sugar art molds, decorative building materials molds, and character and cultural relics replication Reproduction of craft gifts, handicrafts, etc., production of various food grade molds, high-end silicone products, etc.

Features:

The temperature range is -65 ℃ -330 ℃, which can be used for a long time and maintain its soft and elastic properties. Environmentally friendly and non-toxic, certified by SGS, FDA, and ROSH. It has excellent electrical performance and chemical stability, water resistance, ozone resistance, climate aging resistance, non corrosiveness, physiological inertness, non-toxic and odorless, low shrinkage rate, easy operation, good toughness, and other characteristics, and is environmentally friendly and non-toxic.

Usage:

A. B component is mixed evenly in a ratio of 1:1 or 10:1, and after vacuuming and defoaming, it can be poured. The operation time depends on the temperature (0.25-3) hours, and the vulcanization time (room temperature) is 4-8 hours. Heating at 80-120 ° C can vulcanize within tens of minutes. The room temperature quick drying operation time is less than 20 minutes, and the vulcanization time is 1 hour. It can be adjusted according to customer needs, and can be matched with other colors such as red, blue, etc. according to user needs. Especially suitable for adjusting skin tone for making silicone humans.

COMPANY PROFILE

Shenzhen Hanast Technology Co, Ltd. was established on 2019. The factory is located in Sanming City, Fujian Province,

covering an area of 20,000 square meters.

Hanast is a silicone raw material company integrating R&D, production and sales, mainly engaged in conventional silicone

rubber,special silicone rubber, RTV adhesive sealant, two-component electronic potting adhesive, thermally conductive

silicone, thermally conductive silicone grease, lubricating silicone grease, damping silicone grease, platinum vulcanizing

agent and other silicone raw materials.

The products comply with ROHS standard, obtain SGS, Food Grade Certification, and the enterprise passed ISO9001. 2015

certification. Our products have obtained many national invention patents and utility model patents, and are widely used in

silicone kitchenware, high temperature wire and cable, industrial silicone rollers, medical industry, baby products, sporting

goods, adult products, new energy vehicles and other fields.

CERTIFICATIONS

CUSTOMERS

Home

Home

Related Suggestion

Related Suggestion

Nov 17,2023

Nov 17,2023

Tel

Tel

Email

Email

Address

Address