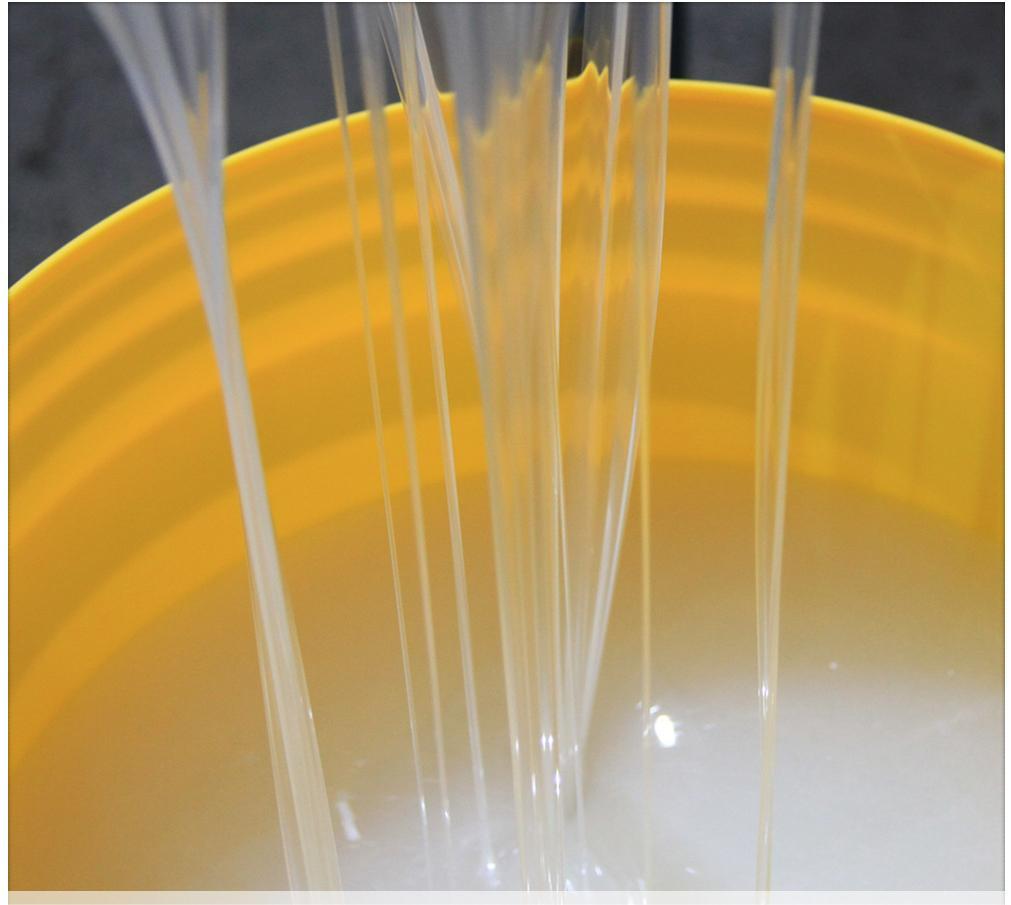

Translucent mold silicone is a two component environmentally friendly silicone composed of A and B components, which can be cured at room temperature or heated for molding. platinum cure liquid silicone Good fluidity, can be poured or applied, and the operation is simple.

Features of semi transparent mold silicone:

1. Passed FDA food grade environmental protection certification, non-toxic and odorless;

2. Good liquidity, simple and convenient operation;

3. It is not limited by the thickness of the product and can be deeply cured, either at room temperature or at elevated temperature;

4. The shrinkage rate is ≤ 0.1%, with dimensional stability. During the crosslinking process, low molecules are not released, so the volume remains unchanged. The silicone mold produced does not deform;

5. Low viscosity, can be poured or brushed, and performance can be adjusted according to customer needs.

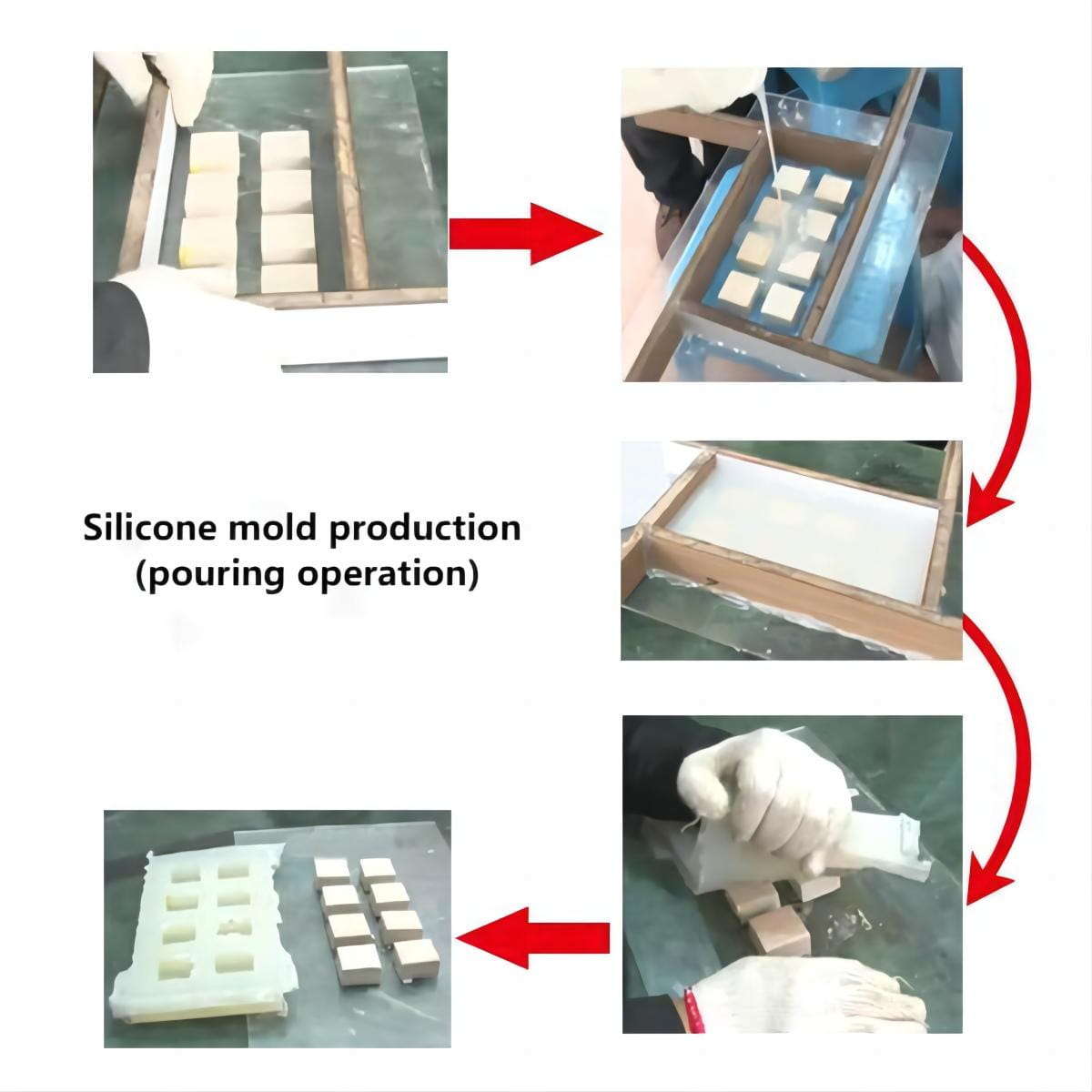

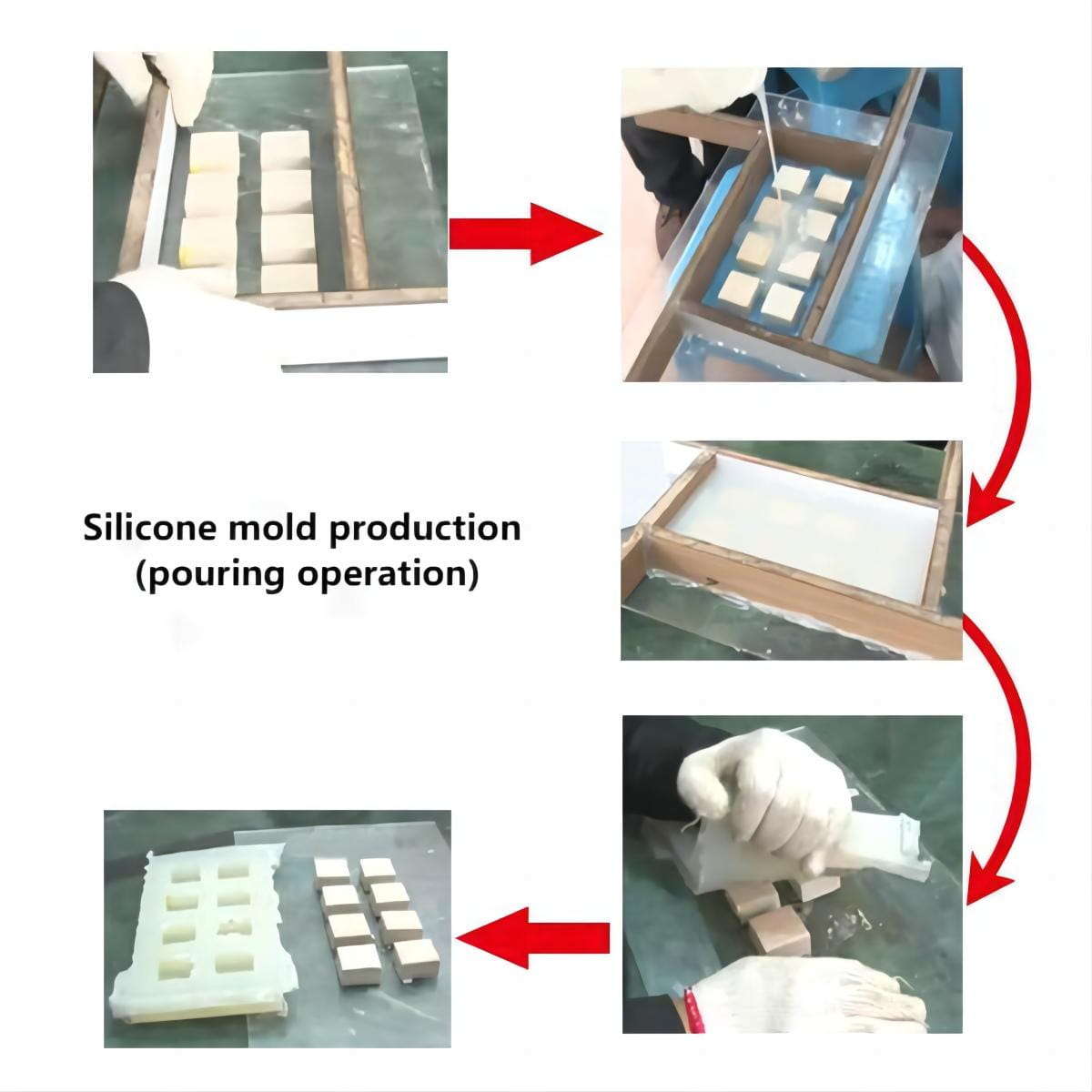

Operation method:

1. Preparation of materials and tools: rulers, knives, brushes, cardboard, etc;

2. Handle the mold properly, fill the bottom of the mold with putty, and make a tenon to ensure that the mold is not misaligned. Remove the tenon from the mold by about one centimeter, and brush the mold release agent (clean water or soapy water) around the mold;

3. Select silicone with appropriate hardness based on the structure, pattern, and purpose of the product, mix and stir evenly in a 1:1 ratio, and place it in a vacuum pump to vacuum to -0.01mpa, making the produced product smoother and bubble free;;

4. Apply the vacuum filled silicone evenly onto the mold, with the first layer of silicone less than 1mm thick, whichever can cover the mold. After the first layer of silicone solidifies, apply the second layer of silicone, which is thicker than the first layer;

5. When the second layer of silicone is not flowing, apply a layer of gauze on top of the silicone to enhance its tear resistance. After trimming the gauze, evenly apply a layer of silicone;

6. After the silicone gel solidifies, trim the surrounding area neatly, divide the mold line reasonably according to the structure of the mold, and fill the part below the mold line with oil mud (the hardness of the oil mud should not be too high). Trim the oil mud around neatly and tightly adhere to the mold type. Making tenons on clay for easy mold assembly;

7. Fix the mold with wooden boards to create a gypsum outer mold, and pour the prepared gypsum onto the mold to repair the surrounding area. After the gypsum solidifies, remove the oil sludge, clean the surface of the gypsum, repeat the above steps, and make the other half of the gypsum outer mold;

8. After the gypsum solidifies, remove the gypsum outer mold and fix it to make a mold for sealing;

9. Clean the bottom of the mold, apply release agent, and wrap adhesive tape around the mold to prevent silicone from overflowing. Add the prepared silicone to make a mold seal, and remove the silicone seal after it solidifies;

10. Remove the gypsum outer mold, flip it out, and then the mold is completed. After 24 hours, it can be put into production.

Precautions:

1. Prevent the addition of silicone gel from coming into contact with heavy metals such as nitrogen, phosphorus, sulfur, tin, cadmium, mercury, etc. Additive silicone is a medical grade silicone that can come into contact with substances containing heavy metals during use, resulting in stickiness, non curing, and incomplete curing.

2. When operating, it should be separated from containers that have used condensed liquid silicone. Before use, a skin test can be conducted on the mold to see if it will solidify before putting it into use.

Hardness selection:

Testing and certification:

Packaging:

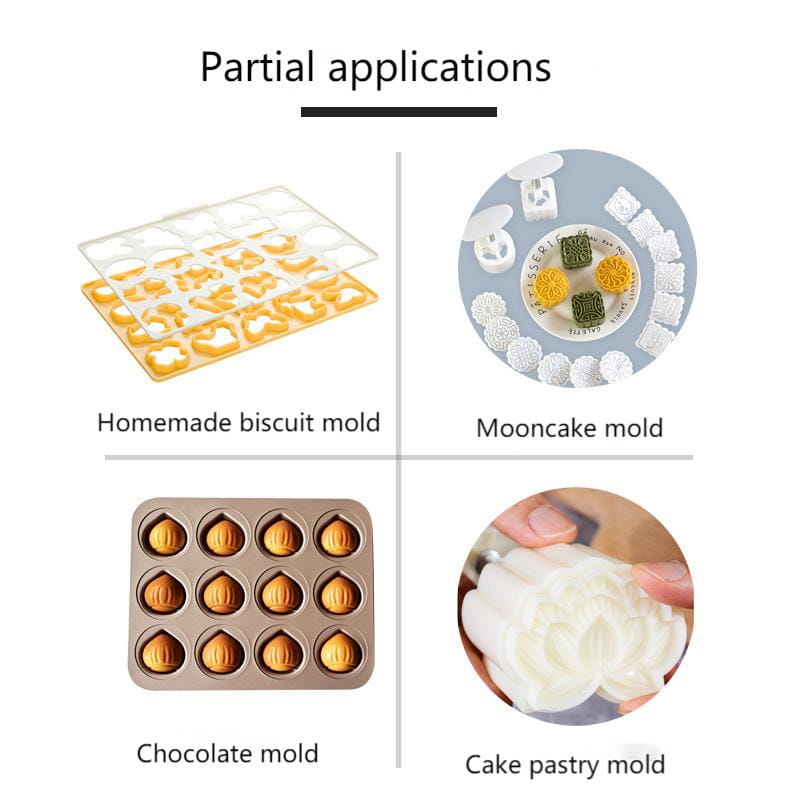

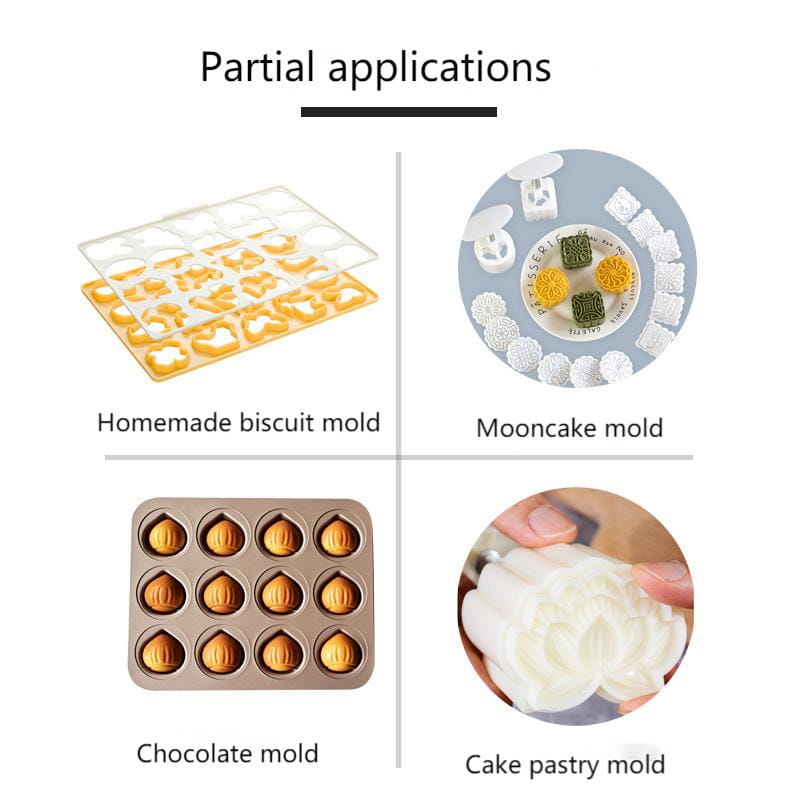

Application scope:

Translucent mold silicone is mainly used in the production of silicone molds for precision products such as resin crafts, handicraft models, carved Buddha statues, car models, military supplies, gift models, metal crafts, alloy vehicles, and food silicone molds such as cakes and chocolates.

COMPANY PROFILE

Shenzhen Hanast Technology Co, Ltd. was established on 2019. The factory is located in Sanming City, Fujian Province,

covering an area of 20,000 square meters.

Hanast is a silicone raw material company integrating R&D, production and sales, mainly engaged in conventional silicone

rubber,special silicone rubber, RTV adhesive sealant, two-component electronic potting adhesive, thermally conductive

silicone, thermally conductive silicone grease, lubricating silicone grease, damping silicone grease, platinum vulcanizing

agent and other silicone raw materials.

The products comply with ROHS standard, obtain SGS, Food Grade Certification, and the enterprise passed ISO9001. 2015

certification. Our products have obtained many national invention patents and utility model patents, and are widely used in

silicone kitchenware, high temperature wire and cable, industrial silicone rollers, medical industry, baby products, sporting

goods, adult products, new energy vehicles and other fields.

CERTIFICATIONS

CUSTOMERS

Home

Home

Related Suggestion

Related Suggestion

Nov 17,2023

Nov 17,2023

Tel

Tel

Email

Email

Address

Address