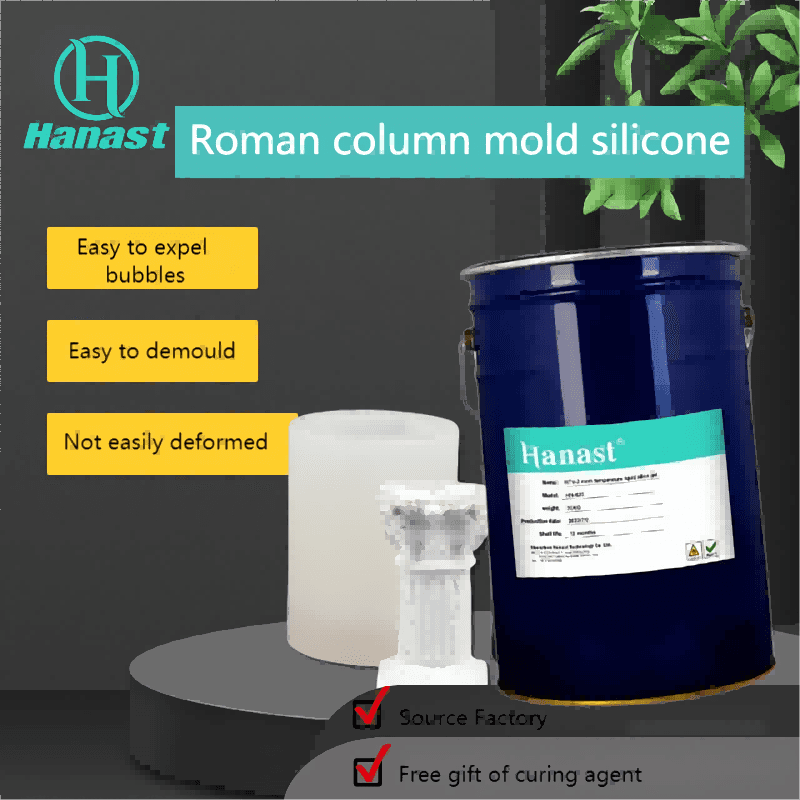

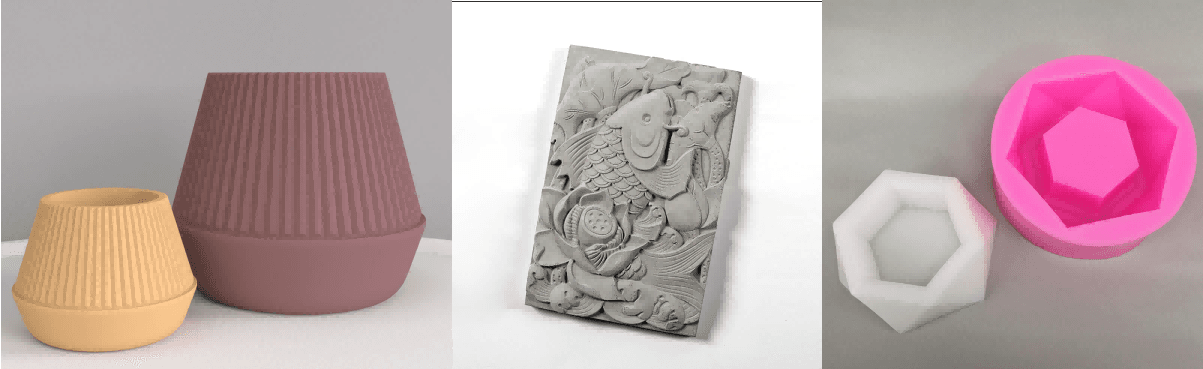

Architectural Decoration Mold Silicone is a mold adhesive specifically used for flipping architectural decorations. It consists of A and B components, A component silicone, B component curing agent, and AB component mixed and stirred evenly in a ratio of 100:2-3 to solidify and form. mold making siliconeSuitable for mold making of products with fine and complex patterns.

Features:

1. Low viscosity, no impurities, moderate softness and hardness, and simple operation process;

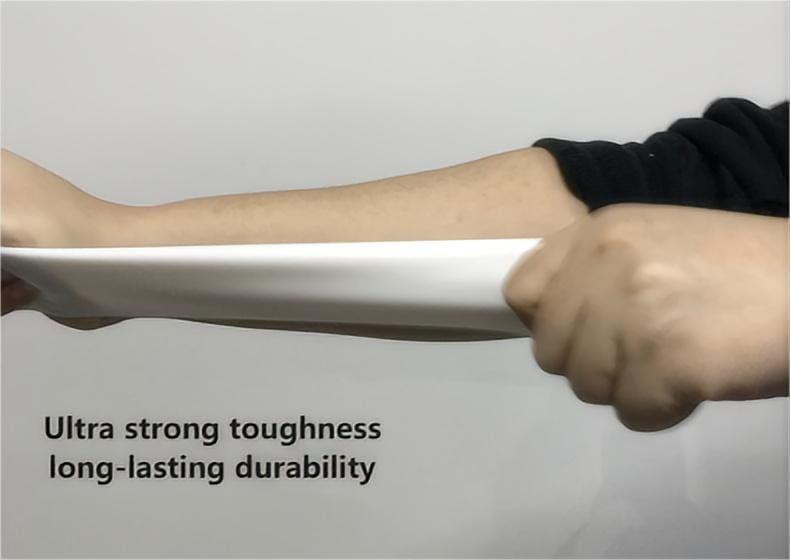

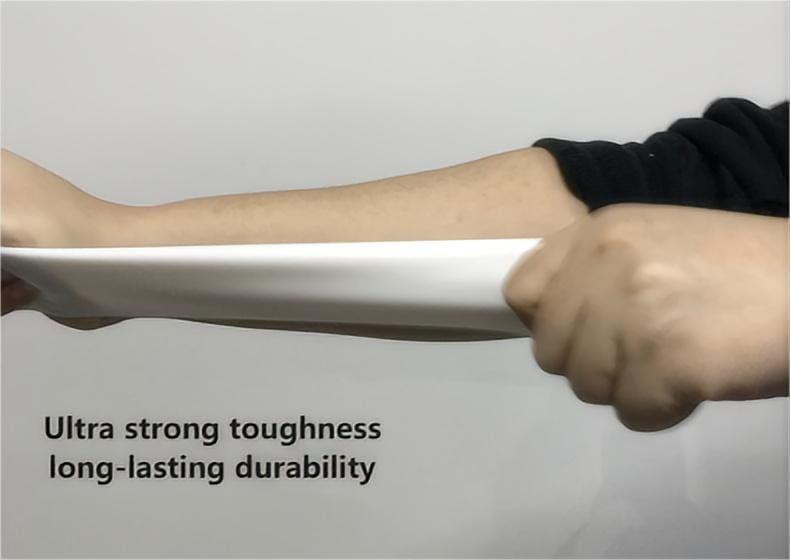

2. High temperature resistance, acid and alkali resistance, strong tear resistance, good tensile strength, multiple mold turns, suitable for mass production of products;

3. The performance of silicone can be adjusted as needed, and the silicone mold produced does not deform or expand;

Operation method:

1. Prepare tools: wooden boards, rulers, knives, brushes, etc;

2. Handle the mold seeds and fix them on the wooden board;

3. Splitting mold line: Divide two or more mold pieces based on the product, making it easy for the product to be demolded. The mold line should be positioned at the highest point of the mold type and should be routed from the inconspicuous joint area;

4. Fill the parts below the mold line with oil mud, and the hardness of the oil mud should not be too high. When stacking, it should be close to the mold type;

5. Install a mortise and tenon about one centimeter away from the mold to facilitate mold closure and prevent mold misalignment;

6. Apply release agent evenly on the surface of the mold, which can be a cleaning agent or soapy water;

7. Mix and stir the gypsum product silicone gel in a ratio of 100:2-2.5 evenly, and place it in a vacuum machine for vacuum extraction (if there is no vacuum machine, the amount of curing agent added can be reduced, the curing time can be extended, and excess bubbles can be released);

8. After vacuum pumping, evenly apply the silicone gel onto the mold, with the thickness of the first layer of silicone less than 1mm, which can cover the mold and oil sludge thinly; After the first layer is cured (about 15 minutes), brush the second layer of silicone. The addition ratio of the second layer of curing agent should be higher than that of the first layer, and the silicone curing time should be controlled within 5-8 minutes; After brushing the second or third layer of silicone, when the silicone is no longer flowing, apply a layer of gauze on top of the silicone to enhance its hardness, and then evenly brush a layer of silicone (increase the gauze appropriately according to the size of the product, generally no more than two layers);

9. After the gypsum solidifies, the gypsum external mold can be made. Secure the cut cardboard around the mold without gaps, and then pour the adjusted gypsum into the mold; After the gypsum solidifies, remove the cardboard, trim the edges of the gypsum outer mold, clean the oil mud on the other side, and repeat the above steps to make the gypsum outer mold on the other side;

After the outer mold is fully cured, remove the cardboard, remove the entire gypsum outer mold and silicone mold, inspect the silicone mold, and trim the mold and outer mold with scissors. At this point, even if all the silicone molds for a gypsum product are completed, they are usually put into production after 24 hours.

Precautions:

The amount of curing agent added should depend on the temperature, which decreases when the temperature is high. If too much curing agent is added, it will affect the quality of the mold, and the silicone mold will become brittle; Adding less curing agent will prolong the curing time;

2. Vacuuming to -0.1mpa is sufficient, and the vacuuming time should not be too long to prevent cross-linking reaction of silicone during vacuuming, causing the silicone to become block by block and causing waste of raw materials;

3. After the production of the silicone mold is completed, it should be stored in a ventilated, cool, and dry place and put into production after 24 hours.

Hardness selection:

Technical parameters:

Application:

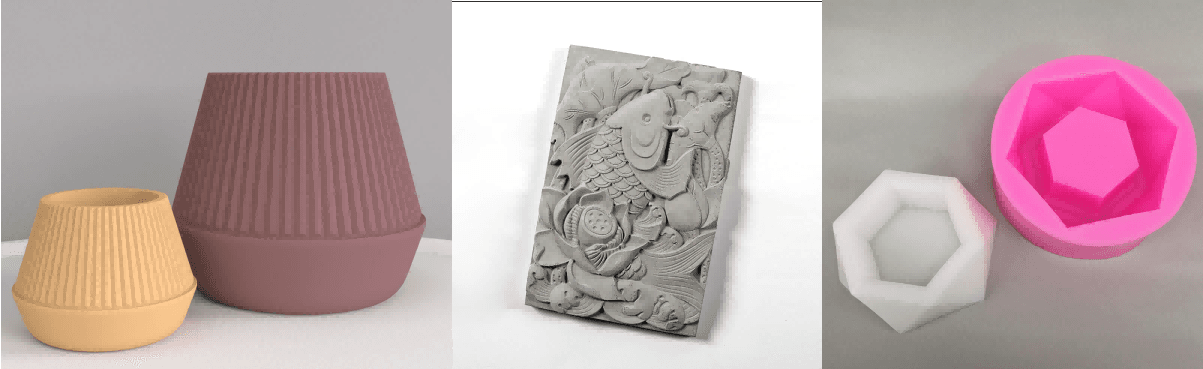

Silicone for architectural decoration molds is widely used in the replication of finely patterned products, mainly for the production of silicone molds for various European style components, gypsum products, cement products, sculptures, statues, statues, handicrafts, and other products.

COMPANY PROFILE

Shenzhen Hanast Technology Co, Ltd. was established on 2019. The factory is located in Sanming City, Fujian Province,

covering an area of 20,000 square meters.

Hanast is a silicone raw material company integrating R&D, production and sales, mainly engaged in conventional silicone

rubber,special silicone rubber, RTV adhesive sealant, two-component electronic potting adhesive, thermally conductive

silicone, thermally conductive silicone grease, lubricating silicone grease, damping silicone grease, platinum vulcanizing

agent and other silicone raw materials.

The products comply with ROHS standard, obtain SGS, Food Grade Certification, and the enterprise passed ISO9001. 2015

certification. Our products have obtained many national invention patents and utility model patents, and are widely used in

silicone kitchenware, high temperature wire and cable, industrial silicone rollers, medical industry, baby products, sporting

goods, adult products, new energy vehicles and other fields.

CERTIFICATIONS

CUSTOMERS

Home

Home

Related Suggestion

Related Suggestion

Nov 17,2023

Nov 17,2023

Tel

Tel

Email

Email

Address

Address