Introduction to Cement Gypsum Mold Silicone:

The Hongye brand cement gypsum mold silicone is a two component liquid silicone that can be cured at room temperature or at elevated temperature. Before curing, the silicone and curing agent are both liquids, and when mixed together, they will solidify into silicone elastomers. Therefore, the silicone mold is the most elastic mold material among all molds, and the gypsum product itself is fragile and vulnerable. Using a silicone mold to flip the mold not only does not damage the structure of the gypsum product, It can also perfectly replicate the fine patterns of gypsum products, making it the preferred turnover material for gypsum cement products.

The main application areas of cement gypsum mold silicone are:

Cement gypsum mold silicone can be mainly used for the production of various gypsum lines, gypsum boards, gypsum buildings, decoration process parts, Roman columns, cement products, cement rockeries, cultural stones, artificial stones, gypsum cement products, and other silicone molds.

Performance characteristics of cement gypsum mold silicone:

1. Good fluidity, easy to pour, easy to operate, easy to demould without damaging the product's grain structure;

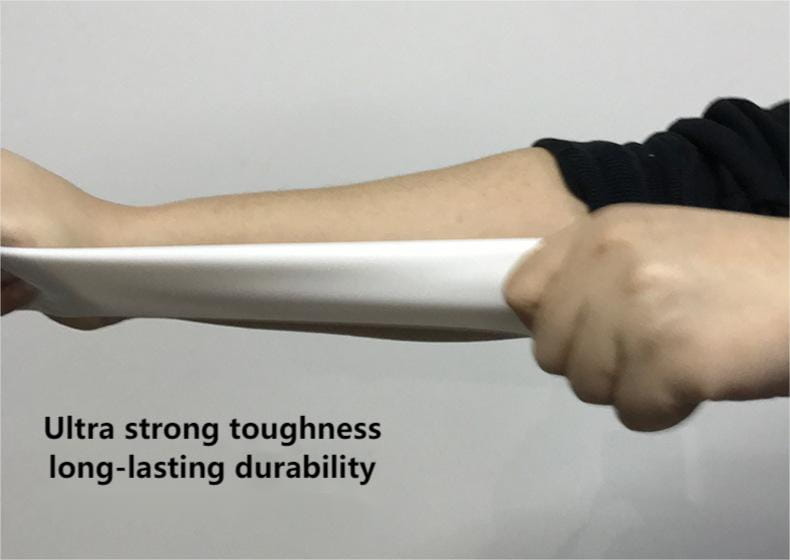

2. Good tensile strength and high tearing strength make the silicone mold very durable. By replicating some simple gypsum products, the mold can be turned over thousands of times;

3. The mold produced is not deformed, resistant to high and low temperatures, aging, and does not swell;

4. Good weather resistance, acid and alkali resistance, low linear shrinkage rate (≤ 0.2%);

5. Room temperature rapid curing, hardness, viscosity, operating time, and curing time can be customized according to customer product requirements.

Instructions for using silicone gel in cement gypsum plaster molds:

This product is liquid silicone rubber, with two components. Component A is liquid silicone and Component B is silicone curing agent. Mix and stir the AB components in a fixed proportion, and they can harden within a few hours. The silicone mold can be solidified and formed.

The ratio of silicone rubber for condensation molds is 100:2, and the ratio of silicone rubber for addition molds is 1:1 and 10:1. Please confirm with the manufacturer.

Selection method for cement gypsum mold silicone:

1. Products with scales ranging from 10 to 20 centimeters have very precise markings, and can be molded using silicone with a hardness of 10 to 20 centimeters;

2. For products with a scale of 30-50 centimeters, the markings are not very complex, and can be molded using silicone at 20-30 degrees Celsius;

3. Products with a scale of over 60 centimeters and very precise markings can be brushed with silicone at 30-40 degrees Celsius.

Precautions for cement gypsum mold silicone:

1. The amount of curing agent added should depend on the temperature, and should be reduced when the temperature is high. Excessive use of curing agents can cause the mold to become hard and brittle; If too little curing agent is used, the operating time will be prolonged.

2. In order to achieve the best application effect of your silicone mold, please store the mold for at least 24 hours before use.

COMPANY PROFILE

Shenzhen Hanast Technology Co, Ltd. was established on 2019. The factory is located in Sanming City, Fujian Province,

covering an area of 20,000 square meters.

Hanast is a silicone raw material company integrating R&D, production and sales, mainly engaged in conventional silicone

rubber,special silicone rubber, RTV adhesive sealant, two-component electronic potting adhesive, thermally conductive

silicone, thermally conductive silicone grease, lubricating silicone grease, damping silicone grease, platinum vulcanizing

agent and other silicone raw materials.

The products comply with ROHS standard, obtain SGS, Food Grade Certification, and the enterprise passed ISO9001. 2015

certification. Our products have obtained many national invention patents and utility model patents, and are widely used in

silicone kitchenware, high temperature wire and cable, industrial silicone rollers, medical industry, baby products, sporting

goods, adult products, new energy vehicles and other fields.

CERTIFICATIONS

CUSTOMERS

Home

Home

Related Suggestion

Related Suggestion

Nov 17,2023

Nov 17,2023

Tel

Tel

Email

Email

Address

Address