Craft Mold Silicone is a liquid silicone mold developed specifically for flip molding crafts. It is composed of AB components, A component silicone, rtv 2 molding silicone rubber and B component curing agent. When used, the two components are mixed and stirred evenly according to a certain weight ratio to achieve room temperature curing and molding. The ratio of added silicone is 1:1, and the ratio of condensed silicone is tin curing liquid silicone100:2-3.

Features:

① Good flowability, low viscosity, and good operability;

② High and low temperature resistance, acid and alkali resistance, and aging resistance;

③ Good tensile strength and tear resistance, and the silicone mold produced does not deform;

④ Low linear shrinkage rate, easy demolding, and frequent mold turnover;

⑤ Color, hardness, viscosity, and operating time can be adjusted as needed.

Operation method:

① Mix and stir the silicone gel and curing agent in a weight ratio evenly (1:1 for addition molding and 100:2-2.5 for condensation type);

② After evenly mixing and stirring, the silicone gel is placed in a vacuum machine for vacuum exhaust bubble treatment. The advantage of doing so is to make the product smooth and bubble free. (Without a vacuum machine, the curing time can be extended to allow bubbles to naturally discharge, but the effect is not very ideal);

③ Spray (apply) a layer of release agent on the already made mold and mold frame, fix the mold in the middle, slowly and steadily pour the liquid silicone that has discharged bubbles into the mold frame until the silicone completely covers the mold, and then let it rest until it fully solidifies;

④ After the silicone gel of the mold is fully cured, demolding can be carried out, and the silicone mold can be removed for edge treatment.

⑤ It is recommended to leave the silicone mold for 24 hours before putting it into use, in order to achieve the best use effect of the mold.

Precautions:

① Silica gel and curing agent must be stirred evenly to avoid non curing of silica gel;

② The prepared liquid silicone should be used up as much as possible within the operable time;

③ When the original model produces glass, ceramics, or is coated with paint, the original model is evenly coated with shampoo solution or soapy water. After the water evaporates, the mold silicone is poured or brushed to facilitate better demolding;

④ Addition silicone and condensation silicone should not come into contact with each other, otherwise it may cause silicone "poisoning" and cause silicone not to solidify;

⑤ During the operation of adding silicone, it should not come into contact with water, impurities, organic tin catalysts, acids, bases, and compounds containing nitrogen, phosphorus, and sulfur. These substances should not be mixed during use to avoid the phenomenon of non curing of silicone.

The operational time and demolding time after the ratio of silicone and curing agent:

When the amount of curing agent added is 1%, the colloid will still flow after 2.5 hours and can be demolded after 6-8 hours;

When the amount of curing agent added is 2%, the colloid will still flow within 50-1 hour, and demolding can be carried out within 2-3 hours;

When the amount of curing agent added is 3%, the colloid will still flow after 28 to 30 minutes, and demolding can be carried out after 1.5 to 2 hours;

When the amount of curing agent added is 4%, the colloid will still flow within 10-15 minutes and can be demolded within 1-1.5 hours.

Hardness selection:

Technical parameters:

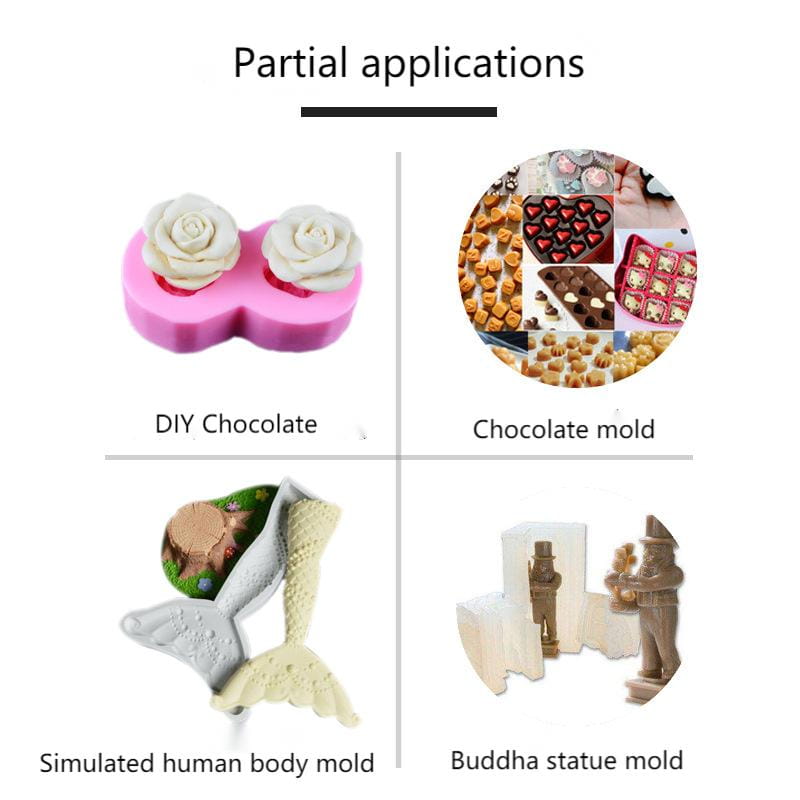

Application scope:

Crafts mold silicone is mainly used for the re molding and precision mold manufacturing of toys, craft gifts, products with fine patterns, packaging molds, injection mold products, POLI crafts, resin crafts, lighting, candles, and other crafts.

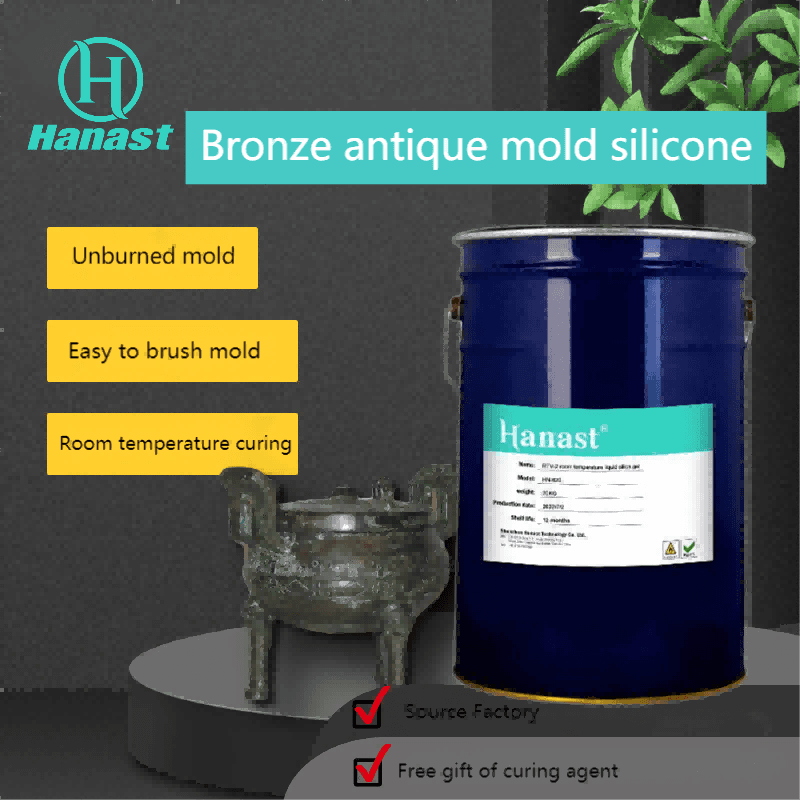

COMPANY PROFILE

Shenzhen Hanast Technology Co, Ltd. was established on 2019. The factory is located in Sanming City, Fujian Province,

covering an area of 20,000 square meters.

Hanast is a silicone raw material company integrating R&D, production and sales, mainly engaged in conventional silicone

rubber,special silicone rubber, RTV adhesive sealant, two-component electronic potting adhesive, thermally conductive

silicone, thermally conductive silicone grease, lubricating silicone grease, damping silicone grease, platinum vulcanizing

agent and other silicone raw materials.

The products comply with ROHS standard, obtain SGS, Food Grade Certification, and the enterprise passed ISO9001. 2015

certification. Our products have obtained many national invention patents and utility model patents, and are widely used in

silicone kitchenware, high temperature wire and cable, industrial silicone rollers, medical industry, baby products, sporting

goods, adult products, new energy vehicles and other fields.

CERTIFICATIONS

CUSTOMERS

Home

Home

Related Suggestion

Related Suggestion

Nov 17,2023

Nov 17,2023

Tel

Tel

Email

Email

Address

Address