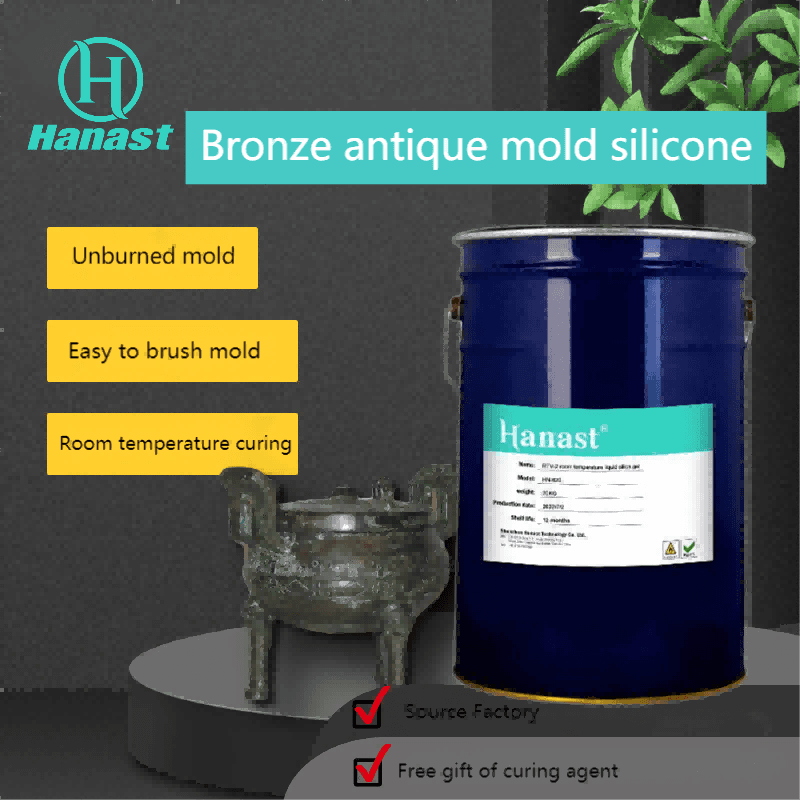

Introduction to Mold Silicone:

Imitation jade table and chair molds generally use condensed mold silicone, while some customers prefer to use additive mold silicone, both of which are two component silicone and liquid silicone rubber; Component A is a flowable liquid silicone, while Component B is a curing agent (vulcanizing agent) that can be quickly formed by mixing the two. Among them, condensed silicone is non food grade, that is, industrial grade silicone, and added silicone is food grade silicone. The following recommended silicone for condensation type molds.

Mold silicone features:

1. Good liquidity;

2. Resistance to burning and high temperature;

3. No bulging or deformation;

4. Good tensile strength and strong tear resistance;

5. Multiple replicates;

6. Corrosion resistance and easy demolding;

Mold silicone application:

Mainly used in the production of imitation jade tables and chairs, imitation jade wash basins, imitation jade mirror frames, imitation jade furniture, imitation jade relief background walls, imitation jade handicrafts, imitation jade stairs, imitation jade Roman columns and other mold silicone.

Mold silicone technical parameters:

Color White

Mixing ratio 100:2

25 ℃ operating time MIN 30-40

25 ℃ curing time H 3-4

Shore hardness 40 ± 2

Tensile hardness Mpa 3.8

Tear strength KN/m 22 ± 2

Viscosity A/B MPa. s 23000 ± 2000

Reduction rate% ≤ 0.2%

Elongation rate% ≥ 310%

Addition/condensation type condensation type

Mold silicone operation method:

1. The mold opening methods for silicone molds are divided into injection mold (wrapping mold), brush mold, and reverse mold.

2. Taking injection molding as an example, the operation method is as follows:

Prepare the mold type → Make the mold frame → Fix the mold type → Weigh the silicone → Stir and vacuum the silicone → Pour the silicone → Cure the mold → Open the mold → Complete

Precautions for using mold silicone:

1. During the production process of silicone molds, incomplete solidification of the mold often occurs, mainly due to incorrect silicone ratio and differences in the curing and insulation time after casting. Of course, it can also be affected by the environment, such as smoking, which can also affect the inability of silicone to solidify.

In order to achieve the best usage effect of the silicone mold, please store the mold for at least 24 hours before use.

3. Ensure the cleanliness of the silicone production container, and do not mix the added silicone with the condensed silicone operating container.

4. Water, impurities, organic tin catalysts, acids, bases, and other organic compounds containing sulfur, phosphorus, and nitrogen can also affect the solidification of silicone. These substances should not be mixed or come into contact during operation.

COMPANY PROFILE

Shenzhen Hanast Technology Co, Ltd. was established on 2019. The factory is located in Sanming City, Fujian Province,

covering an area of 20,000 square meters.

Hanast is a silicone raw material company integrating R&D, production and sales, mainly engaged in conventional silicone

rubber,special silicone rubber, RTV adhesive sealant, two-component electronic potting adhesive, thermally conductive

silicone, thermally conductive silicone grease, lubricating silicone grease, damping silicone grease, platinum vulcanizing

agent and other silicone raw materials.

The products comply with ROHS standard, obtain SGS, Food Grade Certification, and the enterprise passed ISO9001. 2015

certification. Our products have obtained many national invention patents and utility model patents, and are widely used in

silicone kitchenware, high temperature wire and cable, industrial silicone rollers, medical industry, baby products, sporting

goods, adult products, new energy vehicles and other fields.

CERTIFICATIONS

CUSTOMERS

Home

Home

Related Suggestion

Related Suggestion

Nov 17,2023

Nov 17,2023

Tel

Tel

Email

Email

Address

Address