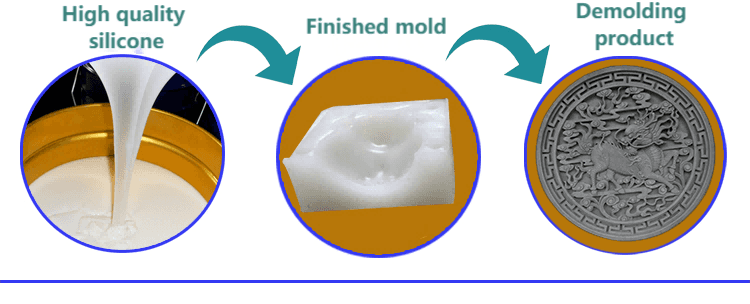

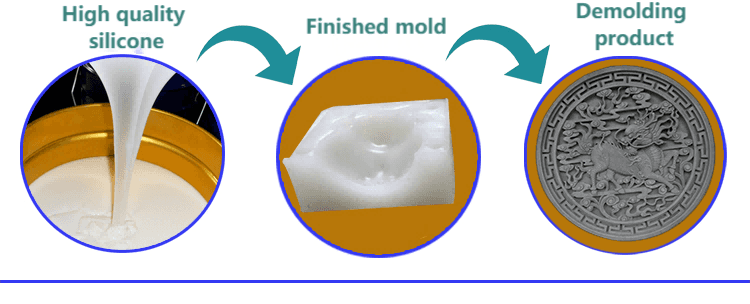

Brick carving mold silicone is a mold adhesive made with a special heat-resistant agent, which makes the silicone mold more heat-resistant. Produced using high-quality raw materials from both domestic and foreign sources, with no impurities and better product performance.

characteristic:

1. Good fluidity, simple operation, non stick mold, easy demolding, and no damage to the mold type;

2. Add special flame retardant to the silicone gel to make the silicone mold more flame resistant;

3. Multiple mold flipping times, good replication effect, long service life of silicone molds, more cost-effective than ordinary silicone;

4. Excellent performance, adjustable according to customer requirements.

Operation method:

1. Mix the silicone gel and curing agent in a ratio of 100:2-3;

2. After mixing the silicone gel and curing agent evenly, carry out the vacuum exhaust bubble process. The vacuum pumping time should not be too long, and under normal circumstances, it should not exceed ten minutes;

3. Polish and polish the mold seeds smoothly, and then apply release agent evenly. Fix the mold seeds on the wooden board with glue;

4. Pour the vacuum filled silicone directly onto the product, wait for the silicone to dry and form, take out the product, and the mold will be formed.

matters needing attention:

1. Silicone and curing agent must be mixed evenly. If not mixed evenly, the silicone will experience uneven drying and curing, which will affect the service life and turnover times of the silicone mold, and even cause the mold to be scrapped.

2. The time for vacuuming should not be too long. Normally, it should not exceed ten minutes. If the vacuuming time is too long, the silicone gel will solidify immediately, causing cross-linking reactions, making it difficult to apply or pour the silicone gel one by one. This will waste the silicone gel;

3. Generally, injection molds are made of silicone with relatively soft hardness, which makes demolding easier and does not damage the products inside the silicone mold;

4. Products or models that need to be replicated before pouring silicone must be coated with release or isolation agents

Application field:

Brick carving mold silicone is suitable for the production and product replication of various brick carving molds. It can also be applied to the replication and mold production of various industries such as cultural stones, cement products, sandstone relief, cultural bricks, GRC components, gypsum lines, and so on.

COMPANY PROFILE

Shenzhen Hanast Technology Co, Ltd. was established on 2019. The factory is located in Sanming City, Fujian Province,

covering an area of 20,000 square meters.

Hanast is a silicone raw material company integrating R&D, production and sales, mainly engaged in conventional silicone

rubber,special silicone rubber, RTV adhesive sealant, two-component electronic potting adhesive, thermally conductive

silicone, thermally conductive silicone grease, lubricating silicone grease, damping silicone grease, platinum vulcanizing

agent and other silicone raw materials.

The products comply with ROHS standard, obtain SGS, Food Grade Certification, and the enterprise passed ISO9001. 2015

certification. Our products have obtained many national invention patents and utility model patents, and are widely used in

silicone kitchenware, high temperature wire and cable, industrial silicone rollers, medical industry, baby products, sporting

goods, adult products, new energy vehicles and other fields.

CERTIFICATIONS

CUSTOMERS

Home

Home

Related Suggestion

Related Suggestion

Nov 17,2023

Nov 17,2023

Tel

Tel

Email

Email

Address

Address