Introduction to Resin Crafts Mold Silicone:

Resin Crafts mold silicone, also known as resin handicraft specialized mold silicone, is a type of condensed liquid silicone rubber. Component A is a flowable liquid, while Component B is a curing agent (vulcanizing agent). After mixing the two, it can be quickly formed and the operation is simple.

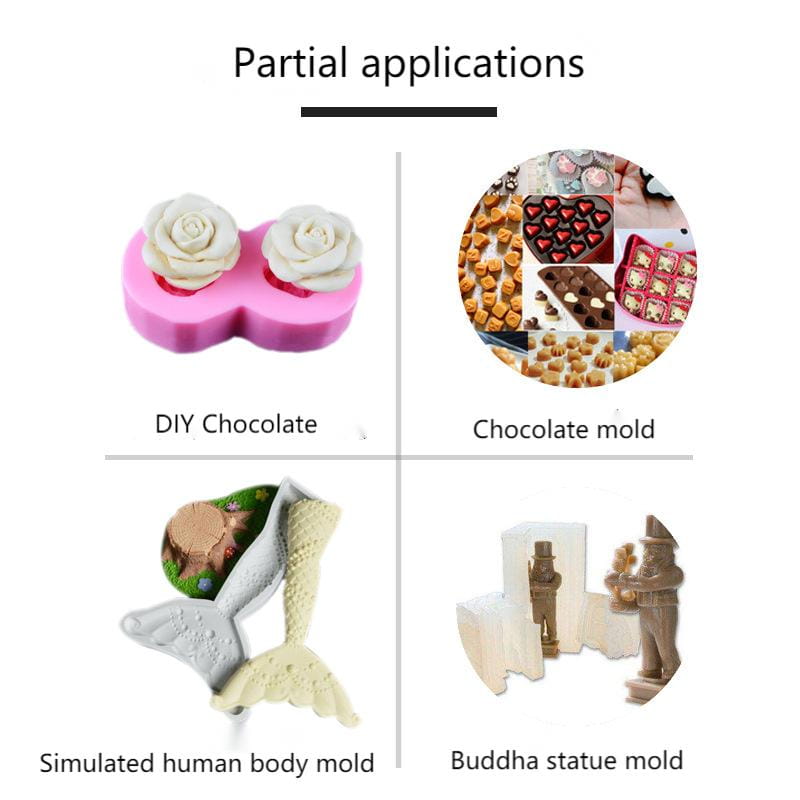

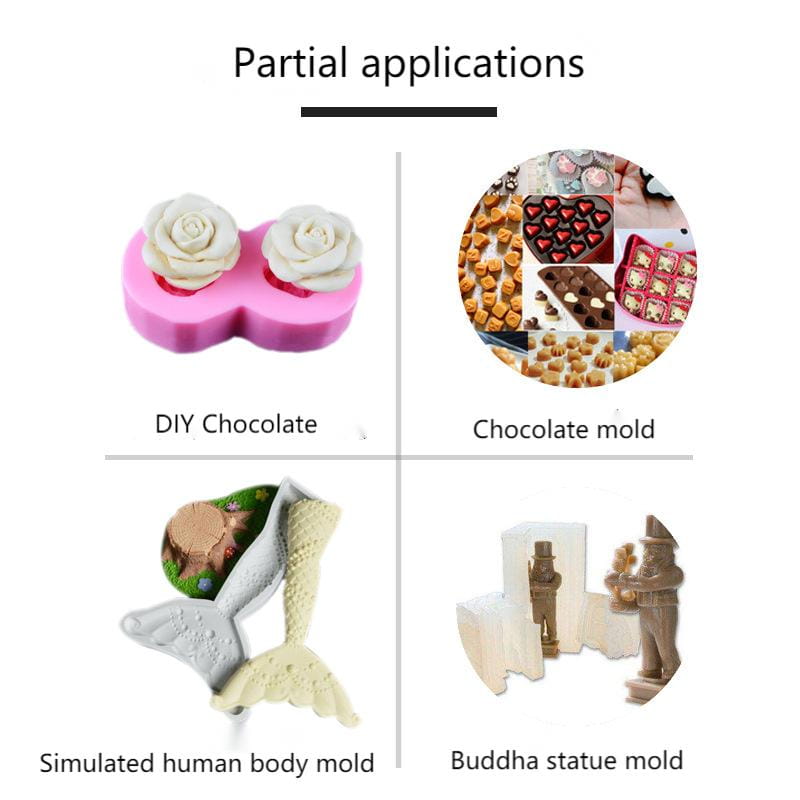

Industry uses of resin handicraft molds silicone:

Suitable for the manufacturing of silicone molds for various large, medium, and small pieces, as well as resin crafts with precise or complex patterns, such as Polyster resin, epoxy resin (EPOXY), Pu resin and other craft gifts, and molds for products with fine patterns. It can also be used for the replication and precision mold manufacturing of lighting, candles, handmade soap and other crafts.

Advantages of silicone in resin handicraft molds:

① High temperature resistance, generally able to withstand 180 ℃ -300 ℃. If special reagents are added, it can withstand even higher temperatures because unsaturated resins release a large amount of heat during the curing process, which can easily damage the silicone mold. Therefore, the advantage of red leaf silicone lies in its better high-temperature resistance, which can significantly save production costs;

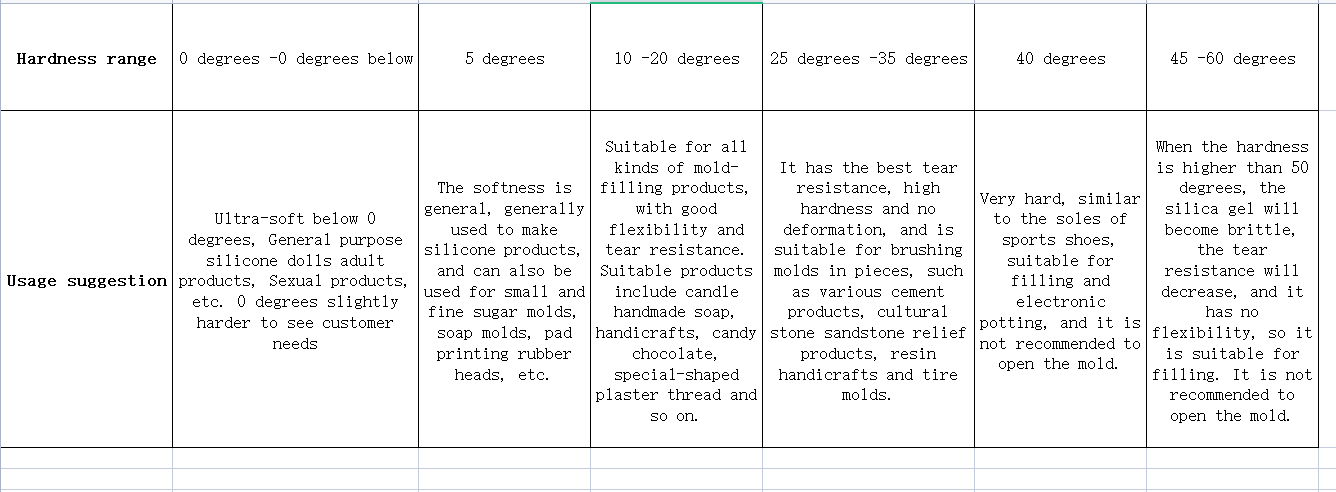

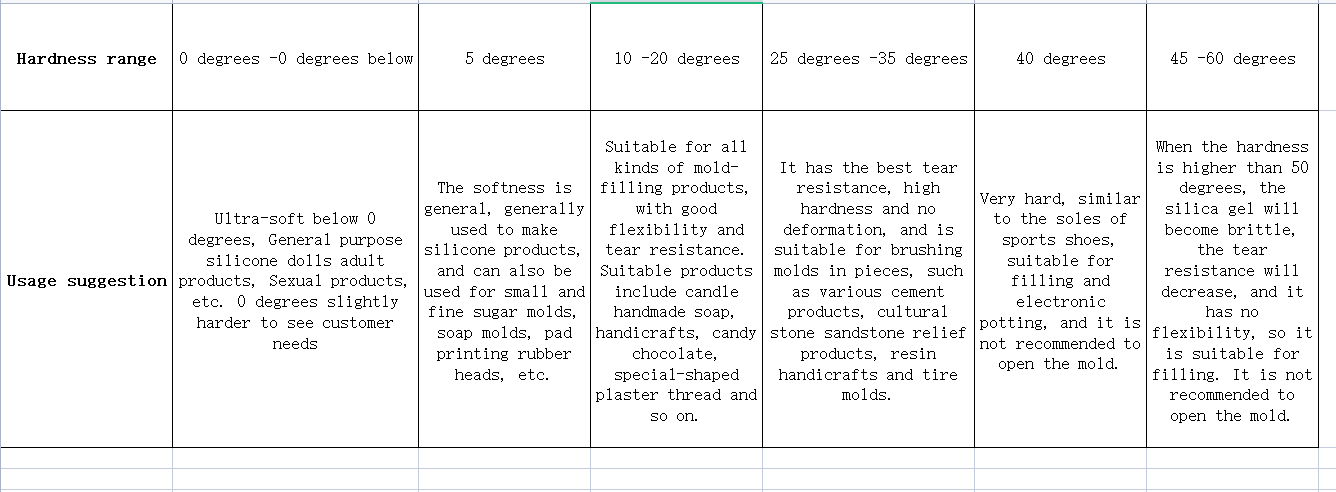

② The viscosity of liquid silicone, the hardness after curing, operating time and curing time, color, etc. can be customized according to customer requirements to produce silicone rubber for you;

③ The shrinkage rate is relatively low, with a shrinkage rate of less than 0.3% for condensed silicone and less than 0.1% for added silicone;

④ The silicone mold produced has good tensile and tear resistance, and does not deform, making it more durable and durable. Therefore, the number of mold turns is also higher.

Instructions for operating silicone in resin handicraft molds:

If customers need to make large products, such as split molds, they need to use high hardness liquid mold silicone to make molds. On the contrary, for complex patterns and fine and small molds, such as packaging molds, they must use soft liquid mold silicone to make molds.

The amount of curing agent added can be determined according to the actual requirements of the customer, requiring quick drying and rapid demolding, and adding more curing agent accordingly. On the contrary, if it is necessary to release the mold slowly, add less curing agent (but the maximum amount of curing agent added should not exceed 5%).

Note: Our company's products do not advocate the addition of silicone oil. For special soft silicone molds or complex patterns and fine precision, 5% -10% silicone oil can be added to adjust the softness of the silicone mold for easy demolding.

The reaction between the ratio of silicone and curing agent is as follows:

1. When the dosage of curing agent is 1%, the colloid will still flow after 2.5 hours, and demolding can be carried out after 6-8 hours.

2. When the dosage of the curing agent is 2%, the gel will still flow within 50 minutes to 1 hour, and can be demolded within 2-3 hours.

3. When the dosage of curing agent is 3%, the colloid will still flow after 28-30 minutes, and demolding can be carried out after 1.5-2 hours.

4. When the dosage of the curing agent is 4%, the colloid will still flow in 10-15 minutes and can be demolded in 1-1.5 hours.

COMPANY PROFILE

Shenzhen Hanast Technology Co, Ltd. was established on 2019. The factory is located in Sanming City, Fujian Province,

covering an area of 20,000 square meters.

Hanast is a silicone raw material company integrating R&D, production and sales, mainly engaged in conventional silicone

rubber,special silicone rubber, RTV adhesive sealant, two-component electronic potting adhesive, thermally conductive

silicone, thermally conductive silicone grease, lubricating silicone grease, damping silicone grease, platinum vulcanizing

agent and other silicone raw materials.

The products comply with ROHS standard, obtain SGS, Food Grade Certification, and the enterprise passed ISO9001. 2015

certification. Our products have obtained many national invention patents and utility model patents, and are widely used in

silicone kitchenware, high temperature wire and cable, industrial silicone rollers, medical industry, baby products, sporting

goods, adult products, new energy vehicles and other fields.

CERTIFICATIONS

CUSTOMERS

Home

Home

Related Suggestion

Related Suggestion

Nov 17,2023

Nov 17,2023

Tel

Tel

Email

Email

Address

Address