Product features and uses:

1. Widely used in electronic, electrical appliances, circuit boards, lighting, switching power supply encapsulation, dipping, coating, waterproof, antifouling.

2. The hardened silicone RTV rubber can give play to the original electrical characteristics of silicone. It has good elongation (it can also maintain its original rubber elasticity against vibration and impact) at the temperature of - 50 ℃~250 ℃, and has weather resistance, heat resistance and cold resistance.

3. This silica gel has passed UL94V-0 certification, halogen-free certification, REACH, ROHs, PAHS.

Product usage and precautions:

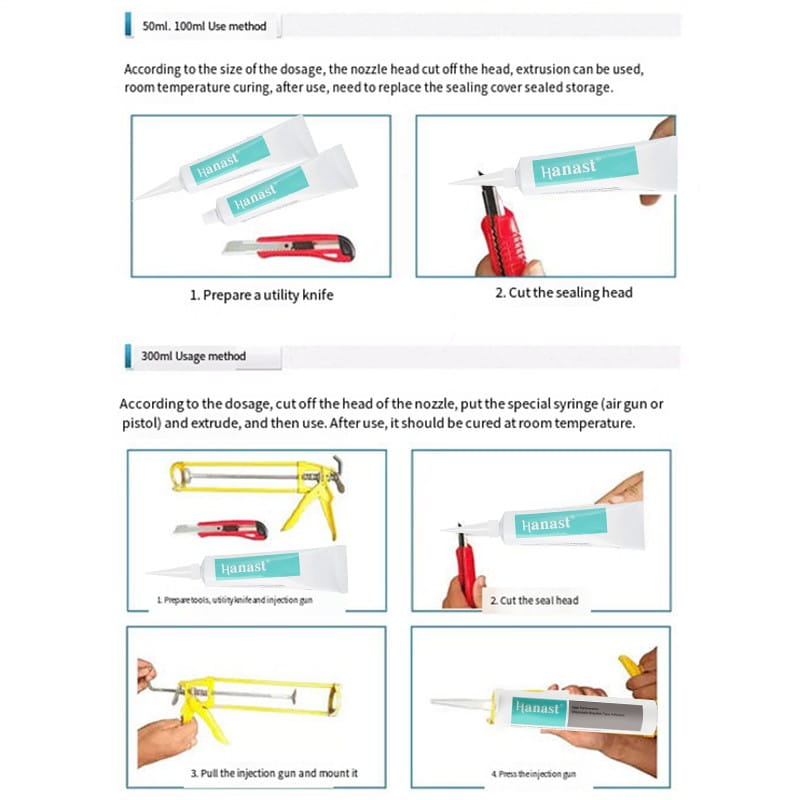

1. According to the dosage, cut off the head of the nozzle, install a special injection tool, extrude it with a glue gun, cure it at room temperature, and fasten the seal cap after use.

2. When using, the adhesive layer must be fully exposed to air. The larger the contact area is, the faster the curing will be. On the contrary, it will be slower or even not cured.

3. The thicker the coating thickness, the longer the curing time, the higher the ambient temperature (not higher than 60 ℃), and the higher the humidity, the faster the curing speed of the adhesive layer, and vice versa.

4. During storage and transportation, the product should be kept dry to prevent exposure to sunlight and high temperature. The valid shelf life is 6 months. Those beyond the shelf life can still be used after passing the inspection.

Product packaging:

100ml aluminum pipe, 300ml plastic pipe, 2600ml plastic pipe

Product series:

one component coated adhesive sealing silicone rubber (transparent, paste) HN-801C-2

|

model

|

HN-801C-2

|

HN-801C-1

|

HN-801B-1

|

HN-801R-1

|

HN-801W-1

|

|

type

|

Alcohol type RTV

|

The ketotaxime type RTV

|

The ketotaxime type RTV

|

The ketotaxime type RTV

|

The ketotaxime type RTV

|

|

surface

|

Transparent, cream-shaped

|

Transparent, cream-shaped

|

Black, paste

|

Red, paste

|

White, paste

|

|

dynamic viscosity (mPa.S)

|

——————

|

——————

|

——————

|

————

|

---------

|

|

Specific gravity (25℃)

|

1.0~1.05

|

0.98~1.0

|

0.98~1.0

|

1.2~1.3

|

1.2~1.3

|

|

Table stem time (min25℃)

|

5~15

|

10~30

|

10~30

|

10~30

|

10~30

|

|

Shaw Hardness (JISA)

|

35~40

|

30~40

|

30~40

|

40~50

|

40~50

|

|

elongation at break (%)

|

300~400

|

300~450

|

300~450

|

250~400

|

250~400

|

|

Tensile Strength (Kgf/ cm2)

|

20~25

|

20~35

|

20~35

|

20~35

|

20~35

|

|

mass resistivity (Ω.cm)

|

≥3×1014

|

≥3×1014

|

≥3×1014

|

≥3×1014

|

≥3×1014

|

|

Breakdown voltage (kv / mm)

|

20~25

|

20~25

|

20~25

|

20~25

|

20~25

|

|

Positive dielectric loss angle (1MHZ)

|

≤4×10-3

|

≤4×10-3

|

≤4×10-3

|

≤4×10-3

|

≤4×10-3

|

|

Resistance to high and low temperature of (℃)

|

-50℃~200℃

|

-50℃~250℃

|

-50℃~250℃

|

-50℃~250℃

|

-50℃~250℃

|

Application case:

1. Bonding and fixing of PC power supply, LED power supply, charger, adapter and various switching power supplies.

2. Glass on doors of ovens, microwave ovens, disinfection cabinets, induction cookers, etc. shall be sealed and bonded, and structural metal fiber gaps shall be sealed to prevent water and air leakage.

3. The coffee pot and electric kettle bases are bonded and sealed.

4. PTC heating parts are bonded and fixed.

5. Bonding and sealing of other emerging household appliances.

Home

Home

Related Suggestion

Related Suggestion

Nov 17,2023

Nov 17,2023

Tel

Tel

Email

Email

Address

Address