Common use description of the product:

1. It is used for the bonding of ABS and PP handles of coffee pot with glass, and the sealing bonding of coffee pot edges.

2. Used for sealing and bonding of PP or ABS materials and stainless steel of household appliances.

3. Used for bonding the heating plate at the bottom of the electric kettle with glass or PC materials.

4. The plastic plate of microwave oven and electromagnetic oven is bonded with the glass ceramics panel.

5. Adhesion of silica gel and plastic for food mold

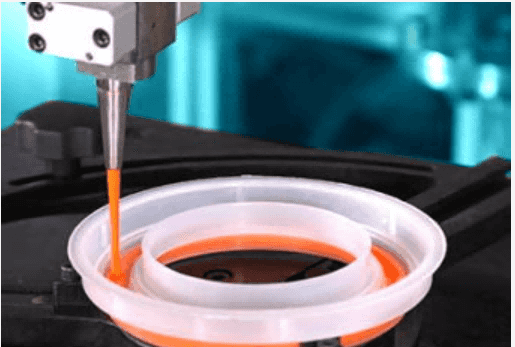

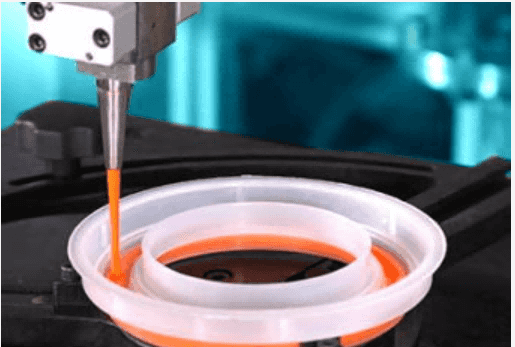

Bonding of kettle base

Organic silicon adhesive HN-601C-1

Product characteristics:

1. Easy operation and simple process.

2. High adhesive strength, good aging resistance.

3. The color is transparent.

4. Long term temperature resistance: 200 ℃.

5. Safety and environmental protection, no harm to people and the environment

| model |

category |

viscosity |

viscosity |

proportion |

Form Time |

Shore hardness |

elongation at break |

tensile strength |

Volume resistivity |

breakdown voltage |

Tangent of dielectric loss angle |

High and low temperature resistance |

| HN-601C- 1 |

Ketoxime type rtv |

Transparent, semi flowing |

____ |

1.0~1.5 |

10~30 |

25-30 |

300~400

|

20~30 |

≥3×1014

|

18~25 |

≤4×10-3 |

-50℃~250℃

|

Glue guide

1. Clean the surface: clean the surface of the stuck or coated objects, and remove rust, dust and oil stains.

2. Gluing: unscrew (or cut off) the rubber tube cap, squeeze the glue to the cleaned surface, make it evenly distributed, and close and fix the glued surface.

3. Curing: place the glued or sealed parts in the air for natural curing. Curing process is a process from surface to interior. The adhesive will be cured to a depth of 3~4mm within 24 hours (room temperature and 55% relative humidity). If the application position is deep, especially the part not easy to contact the air, the complete curing time will be extended. If the temperature is low, the curing time will also be extended. It takes more than 7 days for the 6mm thick sealant to be fully cured

Home

Home

Related Suggestion

Related Suggestion

Nov 17,2023

Nov 17,2023

Tel

Tel

Email

Email

Address

Address