1 、product profile:

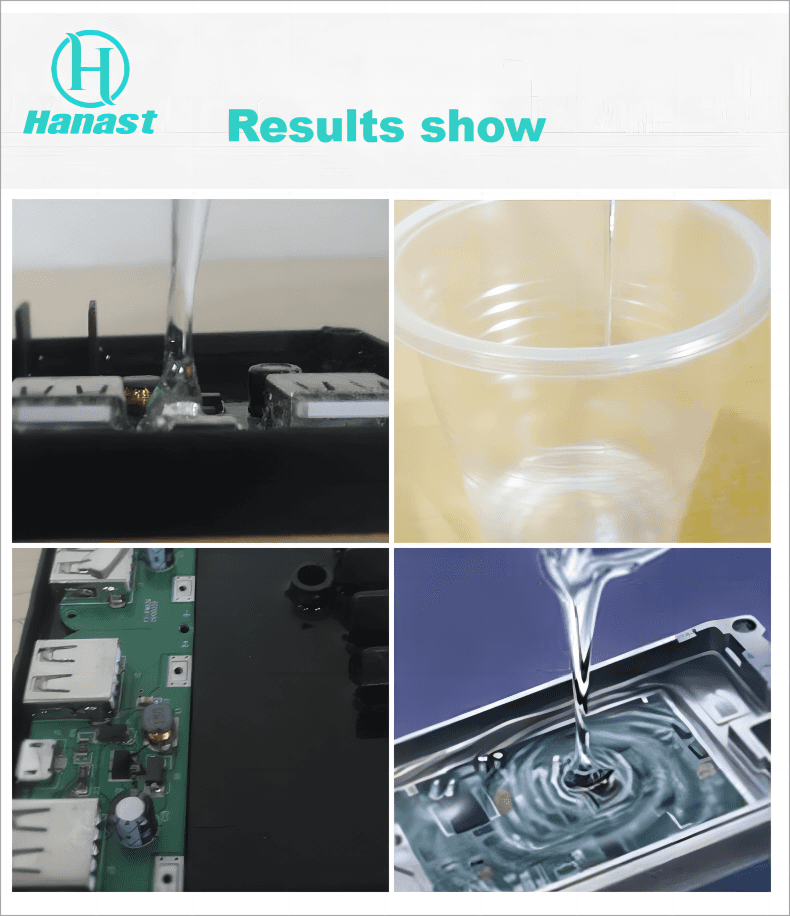

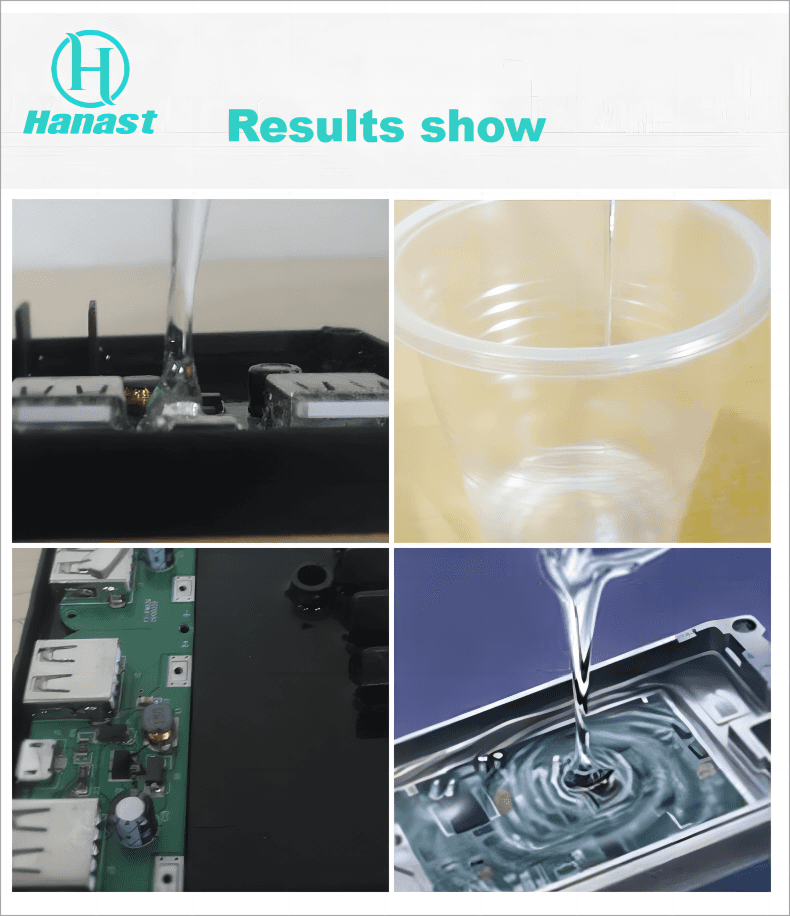

HN-5508 epoxy resin at room temperature or low temperature, with low viscosity, long operation time, good fluidity, and easy penetration into the clearance of the product; no bubbles after curing, smooth surface, luster, high hardness; curing materials have good acid and alkali resistance, moisture-proof, moisture, and air aging; curing materials have excellent insulation, compressive resistance, and bonding strength. Any electronic or other products that require perfusion sealing, packaging protection, insulation, and moisture resistance can be used.

2、second, application scope

HN-5508 is widely used in transformers, resistors, filters, temperature sensors, temperature controllers, ignition coils, high voltage packs, aquarium equipment, anion generators, ultrasonic atomizers, and electronics and other components that require insulation, flame retardant, and temperature resistance. It has flame retardant insulation, sealing bonding, moisture-proof earthquake resistance, temperature resistance, and other main functions.

3、technical parameter

|

Before curing

|

builder

|

Epoxy resin 5508

|

Curing agent 5508

|

|

pigment

|

Black / White et al

|

Ruburn / transparent surface

|

| |

A sticky epoxy resin water

|

r liquid specific

|

|

c gravity, g / cm3

|

1.4-1.5

|

1.05

|

|

Viscosity of 25℃

|

4,500—6,000cp s

|

150—250cp storage

|

|

e Period (25℃)

|

Six months

|

x months

|

|

processabili

|

mixing ratio

|

A: B =5:1 (weight ratio)

|

|

Available for a time of 25℃

|

2-3H (100g mix)

|

|

curing time

|

25℃ / 6-8H surface stem, 12-16H fully cured or 60-80℃/1.5-2H

|

|

After curing

|

2 Tensile strength of kg/cm

|

16-18

|

|

2 Compressive strength of kg/cm

|

18-22

|

|

Resistance to the voltage of kv/mm

|

20-22

|

|

Surface resistance ofΩ-cm

|

14

1.2*10

|

|

Volume resistance ofΩ-cm

|

15

1.1*10

|

|

contraction percentage%

|

0.35-0.55

|

|

Water absorption rate was 25℃ * 24H

|

<0.03%

|

|

The hardness of SHORE A

|

85-95

|

|

distortion

temperature ℃

|

130-150

|

|

low temperature resistant ℃

|

-30

|

The above performance data were measured at 25℃ after 55% relative humidity. The Company is not responsible for different data caused by different test conditions or product improvements.

4. matters need attention:

1. This product is an AB agent, according to the label ratio on the product package, and the mixing ratio is weight ratio and non-volume ratio.

2, AB agent mixing can not be stirred with a round bar without resistance, must be stirred with a flat tool with resistance, it is best to use a small mixer.

3. This product should be placed in a cool and dry place to avoid light, keep the workshop dust-free, and cover the unused glue after opening the lid in time.

4. The performance test data is the test result when the humidity is 60% and the temperature is 25℃, for customer reference only.

5, resin glue stored in a wet environment will exhibit a crystallization phenomenon, please put it in the oven at a low temperature hot dry, and restore its original state.

5. packing specifications

This product is 30 KG per group; including group A 25 KG (barrel) and group B 5 KG (pot)

vi. storage and transportation

1. Store in a cool and dry place with a storage period of 6 months (25℃).

2. Products beyond the storage period should be confirmed whether there are any abnormalities before being used.

3. Parts A and B of the colloid must be sealed and preserved, with careful leakage during transportation!

4. These kinds of products are non-dangerous goods and can be transported as general chemicals.

Home

Home

Related Suggestion

Related Suggestion

Nov 17,2023

Nov 17,2023

Tel

Tel

Email

Email

Address

Address