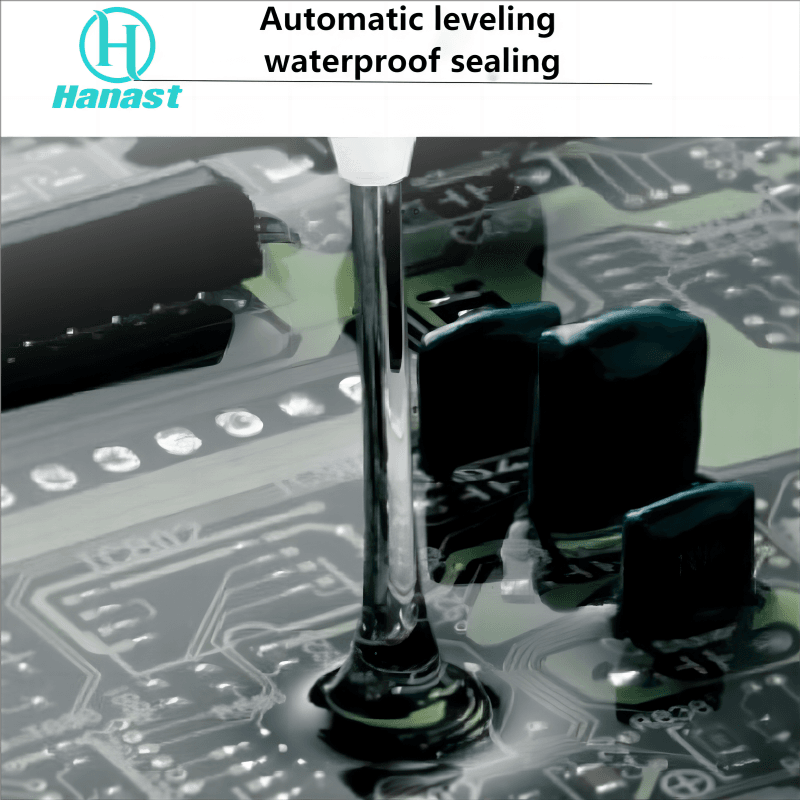

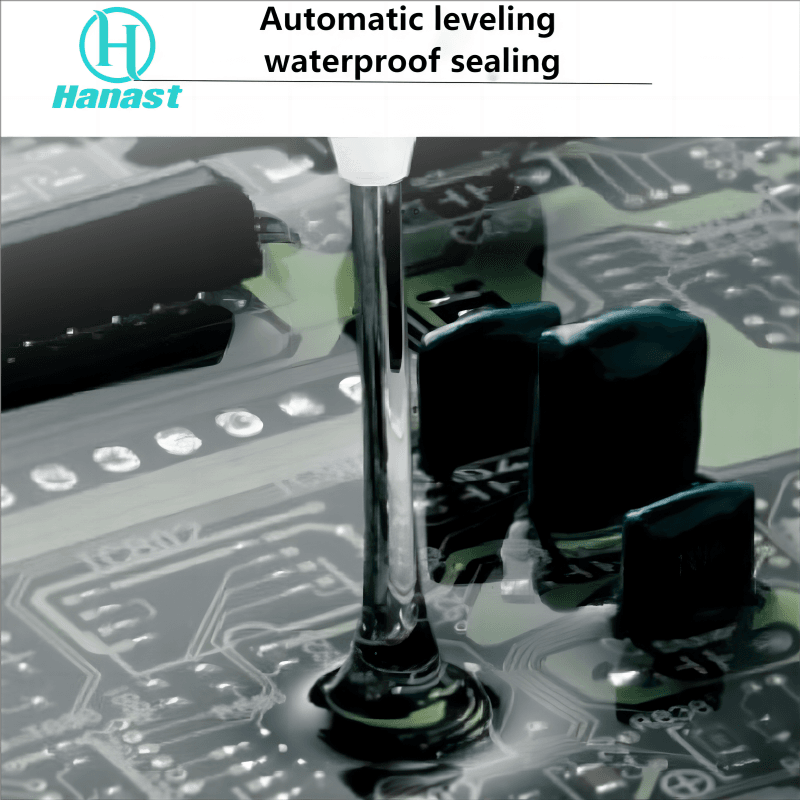

Product Description:

This product is a very soft, low cross-linking density addition silicone rubber. It is a low-viscosity liquid before vulcanization. After vulcanization, in addition to the general characteristics of addition silicone rubber, it has good shock absorption, moisture resistance and sealing due to its soft nature. properties and excellent dielectric insulation properties over a wide range of temperature and humidity.

Product Features:

1. Medium temperature curing, the curing time can be adjusted according to different temperatures;

2. It is low-viscosity silicone oil before curing and gel elastomer after curing.

Physical Properties:

|

Characteristics before curing

|

|

Component

|

Component A

|

Component B

|

|

Color

|

Transparent liquid

|

Transparent liquid

|

|

viscosity(cp s. 25℃)

|

800~2000

|

800~1800

|

|

Relative density(mpa•s)

|

1 .0~1.12

|

0.98~1.02

|

|

The mixing ratio

|

A:B=1:1

|

|

Viscosity after mixing(cp s. 25℃)

|

800~1500

|

|

Operate Time (25℃)

|

2 h

|

|

Penetration (1/10mm)

|

~

200 400

|

|

Curing conditions (120℃)

|

20~30 分钟

|

|

Cured properties

Hardness(Shore A, 24hr)

|

0~10

|

Instructions:

1. Before mixing, component A needs to be properly stirred manually or mechanically, and component B should be fully shaken in a sealed state before use.

2. When it needs to be attached to the application material, please confirm whether it can be attached before use, and then apply it. 3. Before construction, please weigh and mix according to the weight ratio of A:B = 1:1, and stir thoroughly before applying glue.

Package:

This product is 40KG per group;

Component A is 20KG (in barrels), and Component B is 20KG (in barrels)

Storage and transportation:

1、Store in a cool and dry place. The storage period is 6 months (at 25℃).

2、 Products that have exceeded the shelf life should be confirmed for any abnormalities before use.

3、Components A and B of the colloid must be sealed and stored, and be careful of leakage during transportation!

4、Such products are non-dangerous goods and can be transported as general chemicals.

Home

Home

Related Suggestion

Related Suggestion

Nov 17,2023

Nov 17,2023

Tel

Tel

Email

Email

Address

Address