What should I do if liquid silicone mold sticks when pouring it?

Dec 26,2023

Dec 26,2023

Hanast

Hanast

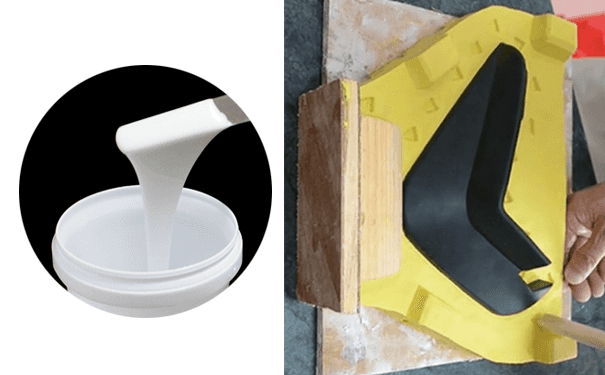

When we use liquid silicone for production, various situations will arise. Among them, I believe many customers have encountered the problem of mold sticking. This situation is actually easy to solve.

The sticky mold is generally very troublesome and difficult to pull out. If it is a very deep metal mold, it must be soaked in white electric oil. Generally, after soaking for 2-3 days, the sticky mold can be soaked away. The polishing paste will polish the inside of the mold. Sand and polish, then spray release agent.

If it is a resin mold to stick to the mold, the scrapped mold can no longer be used, and a new mold can only be used. The new mold needs to be soaked in detergent and water for 2-4 hours. The ratio of detergent to water is 1 :4. After soaking, use an oven to dry the mold. This way the product will no longer stick to the mold.

In fact, there are many reasons for mold sticking, which are related to the material of the mold and the raw material of silicone. At this time, you need to choose high-quality silicone raw materials.

Home

Home

Causes of aging of liquid silicone products

Causes of aging of liquid silicone products  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address