Household appliance sealant disinfection cabinet panel adhesive

Apr 13,2023

Apr 13,2023

Hanast

Hanast

Product use:

Glue colors include transparent, black, red, and white, with a paste like state.

Disinfection cabinet panel adhesive.

The overall curing speed of modified silicone is 20% faster than that of existing market products, and the bonding strength is three times higher than that of existing market products.

This adhesive sealant is waterproof and leak proof for the sealing of cavities, panels, adhesive seals, and gaps in structural metal parts

This silicone has passed halogen-free certification, REACH, ROHS.

Product Features:

It has excellent properties such as flame retardancy, bonding, fixation, sealing, electrical, insulation, moisture-proof, shockproof, and aging resistance.

It can firmly bond with most materials such as metal, glass, ceramic tiles, plastic, and their alloys.

The hardened silicone RTV rubber can exert the original electrical properties of silicone, have good elongation (can maintain its original rubber elasticity against vibration and impact) at temperatures between -50 ℃ and 200 ℃, and have weather resistance, heat resistance, and cold resistance.

Methods and precautions for use:

According to the dosage, cut off the sealing head of the nozzle head, install a dedicated injection tool to extrude and use. Cure at room temperature, and tie the sealing cover after use.

★★ Note 1: When using, the adhesive layer must be fully exposed to air. The larger the contact area, the faster the curing. Conversely, it will slow down or even not cure.

★★ Note 2: The thicker the coating thickness, the longer the curing time, the higher the ambient temperature (not higher than 60 ℃), and the higher the humidity, the faster the curing speed of the adhesive layer, and vice versa.

★★ Note 3: This product should be kept dry during storage and transportation to prevent exposure to sunlight and high temperatures. The effective shelf life is 6 months, and those that exceed the shelf life can still be used after passing the inspection.

★★ Note 4: Clean the surface: Clean the surface of the adhesive or coated material and remove rust, dust, and oil stains.

★★ Note 5: Gluing: Unscrew (or cut) the cap of the hose, squeeze the glue onto the cleaned surface, distribute it evenly, and fix the adhesive surface together.

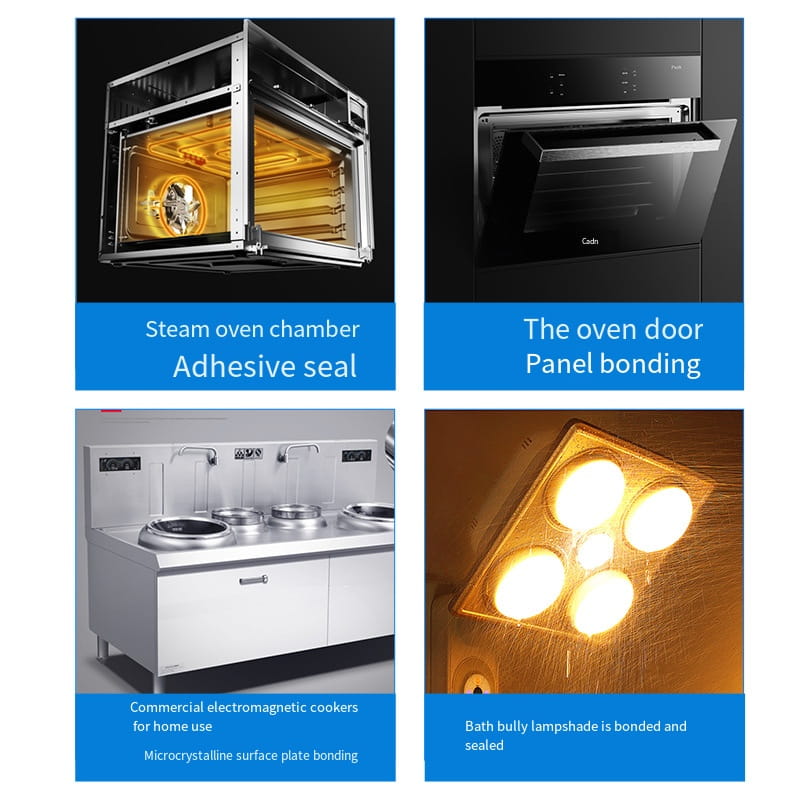

Range of use:

Widely used for bonding, fixing, insulation, shockproof and other applications in electronic appliances, comprehensive small household appliances, instrument analysis, etc.

Insulation sealing, anti leakage, moisture-proof and shockproof for heating components of household appliances; Reinforcement and sealing of refrigerators and refrigeration equipment, bonding and sealing of microwave ovens, circuit boards, electronic components, solar energy fields, and mechanical bonding and sealing.

Suitable for adhesive sealing with high requirements for thermal conductivity.

Bonding and sealing of various household appliances such as induction cookers

rtv material

Packaging specifications

100ml 、 300ml、 2600ml

Recommended models:

HN-801C-2, HN-801C-1, HN-801B-1, HN-801R-1, HN-801W-1

Home

Home

Ball bulb lamp sealant_ Meteor lamp waterproof silicone

Ball bulb lamp sealant_ Meteor lamp waterproof silicone  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address