Glue solution for new energy automobile industry

Dec 06,2022

Dec 06,2022

Hanast

Hanast

Glue for electric control of motor:

Gel Encapsulation

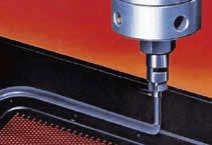

「 Frame bonding and sealing 」

Thermal conductive and flame retardant bonding of components

Gel heat conduction at heating part

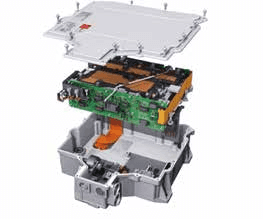

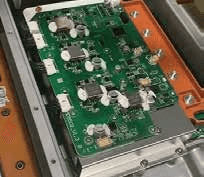

「 Thermal conductive encapsulation of DC-DC, OBC and inverter power supply 」

Glue for charging post:

Thermal Conductivity Encapsulation

1、Motor controlled gel filling

Silicon gel can be cured at room temperature or by heating. After curing, it is in the form of semi solidified gel. It can replace imported products of the same type, and is used for the potting protection of motors, motor controllers, IGBT modules, precision electronic components, sensors, and electrical and electronic modules against water, moisture, and gas pollution.

Product features:

·Solventless, good adhesion and sealing to most substrates

·It has good cold and thermal shock resistance, mechanical vibration resistance and high temperature yellowing resistance

·Good fluidity, fast filling and leveling

2、Bonding and sealing of electric control frame of motor

HN-806W-26 is a single component silicone adhesive sealant, which can be quickly cured by heating and is easy to use. It can replace imported products of the same type. It is used for bonding electric control frames of new energy vehicles, sealing protection of ECU sensor ABS and battery pack shell, and sealing protection of circuit boards and modules.

Product features:

·Good thixotropic property

·It has good adhesion performance to various materials

·Excellent heat resistance, good chemical stability, high and low temperature resistance

3、Heat conduction and flame retardant bonding of electric motor control components

Hanast heat conductive and flame retardant adhesive is a kind of one component dealcoholized sealant. It is a neutral silicone sealing material cured by absorbing moisture in the air. After complete curing, it forms a flame retardant three-dimensional mesh elastic silicone rubber. It does not produce toxic gas during combustion, and has excellent high and low temperature resistance (- 40 ℃~+180 ℃) to maintain stable flame retardancy. After curing, it can be compatible with Haoming potting adhesive products and used for heat conduction, flame retardancy, bonding and sealing of electric motor and other components.

roduct features:

·Solvent free, non-toxic and corrosion free

·Good adhesion to metals and most plastics

·Conform to EU RoHS regulations

4、Motor electric control DC-DC, OBC And inverter power conduction encapsulation

Hanast heat conduction potting adhesive can be solidified in greenhouse and accelerated by heating. It has good fluidity and is easy to fill the gap between electronic components. The operation time and curing speed can be adjusted to adapt to the machine's automatic, semi-automatic and manual potting process. After curing, the encapsulated products can be moisture-proof, waterproof, dust-proof, shockproof and insulated to extend the service life of the power supply. It can be used for heat conduction and sealing of various complex components such as electric motor control DC-DC, OBC and inverter power supply.

Product features:

·No solvent or by-product, minimal shrinkage

·Low specific gravity, good adhesion, flame retardancy and high thermal conductivity

·Good flow performance and thermal shock resistance

5、Charging pile heat conduction sealing

Hanast heat conduction potting adhesive can be solidified in greenhouse and accelerated by heating. It has good fluidity and is easy to fill the gap between electronic components. The operation time and curing speed can be adjusted to adapt to the machine's automatic, semi-automatic and manual potting process. After curing, the encapsulated products can be moisture-proof, waterproof, dust-proof, shockproof and insulated to extend the service life of the power supply. It can be used for heat conduction encapsulation of various complex components such as charging piles.

Product features:

·No solvent or by-product, minimal shrinkage

·Good adhesion, flame retardancy and high thermal conductivity

·Good flow performance and thermal shock resistance

Home

Home

Power battery glue solution

Power battery glue solution  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address