Main types and solutions for new energy vehicle power batteries

Nov 08,2022

Nov 08,2022

Hanast

Hanast

Adhesive are substances that connect two or more parts or materials together through adhesion and cohesion at the interface. Electronic adhesive is a subdivision product of adhesive, which is mainly used for bonding, sealing, filling, coating, structural bonding, common film coating and SMT patch of electronic and electrical components

As the domestic innovative science and technology enterprise strength rising, all kinds of adhesive products application field expanding, in 5G communications, electronic appliances, power batteries and new energy vehicles, Internet of things, machinery manufacturing, light industry and daily life, and many other fields gradually produce new product demand, adhesive materials and adhesive become a field of lightweight, high bonding, improve the efficiency of important products.

In recent years, with the rapid growth of the downstream industry demand, the adhesive technology for power batteries has been conquered by a few domestic enterprises, and the substitution trend of localization has gradually emerged. Haneister New material has accumulated a certain technical strength and application in the power battery BMS battery management system and the same type of new energy storage battery management module protection, thermal conductivity and bonding fixation and other multiple scenario requirements, to help the battery to cope with the more complex use environment, high performance and reliability requirements.

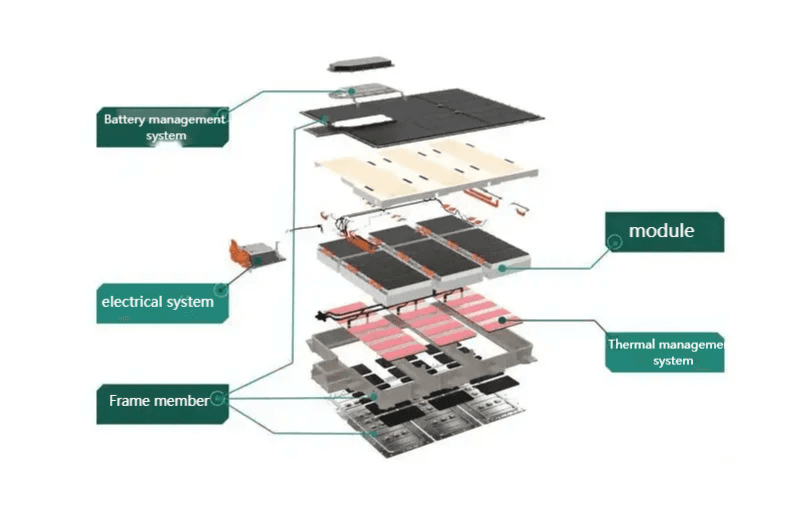

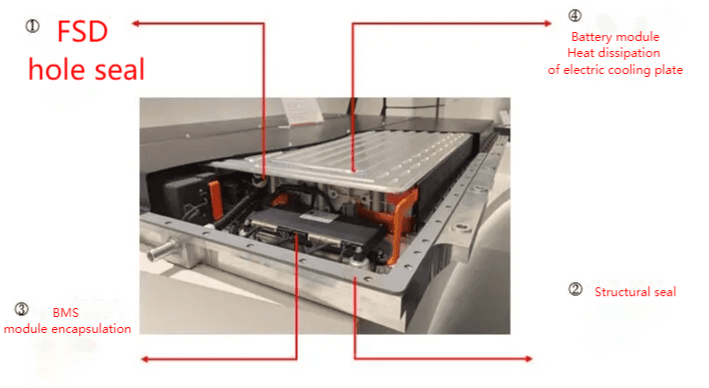

It is understood that the CTP structure battery pack for new energy vehicles, in the design of saving or greatly save the intermediate module components, and turn to use a large amount of glue to connect the fixed cell. The application of these adhesive mainly has two demand points: the first type is for structural adhesive, mainly structure adhesive, considering a certain thermal conductivity; the second type is for thermal adhesive, namely thermal adhesive, the purpose of the adhesive application is the core working heat generated to the external heat dissipation components, to realize the function of thermal management, take into account the requirements of structural bonding.

Structural adhesive refers to the adhesive applied in the stressed structural parts bonding occasions, which can withstand a large dynamic load, static load and can be used for a long time. Instead of bolts, rivets or welding and other forms used to join the metal, plastic, glass, wood and other structural components, belongs to a long time to withstand a large load, and the performance is still reliable adhesive.

Structural glue needs to play the role of reliably connecting and fixing the electric cell and the pack shell, replacing the mechanical connection of the original module structure, and puts forward high performance requirements for strength, flexibility, aging resistance, flame retardant insulation and thermal conductivity.

Structural Sealed HN-806 Series

Power battery pack structure glue mainly includes polyurethane structure glue, acrylic structure glue, silicone gel, epoxy structure glue, UV glue and high temperature resistant hot melt glue, which are applied to different scenarios according to its different characteristics.

For different types of structural glue, there are three specific indicators to evaluate its bonding performance: the strength of the joint, the damage form (cohesion destruction is the most ideal form, reaching the maximum strength of the material at the joint) and the fracture elongation of the glue (reflecting the colloid elasticity).

Thermal conductive adhesive is mainly used to complete the heat conduction between the cell and the cell, as well as between the cell and the liquid cooling tube. The specific use form of the adhesive includes gasket, filling, filling, etc.

Heat sealing HN-8806 series

The heat-conductive adhesive is mainly composed of resin matrix (epoxy resin, silicone and polyurethane, etc.) and thermal conductive filler (improve thermal conductivity, aluminum nitride (AlN), boron nitride (BN) and silicon nitride (Si3N4), alumina (Al2O3), magnesium oxide (MgO), zinc oxide (ZnO), etc.). Battery pack under the development trend of CTP, battery manufacturers have a large demand for thermal conductivity adhesive and have the demand for reducing cost, while reducing the design of structural parts to use adhesive high strength (greater than 10Mpa) adhesive fixed demand, so in the adhesive strength, economic cost of polyurethane thermal conductivity structure adhesive has become the mainstream choice of thermal conductivity adhesive.

Because the optimal working temperature band of the battery cell is narrow (20-40℃), the thermal conductive adhesive under the CTP structure between the cell, between the cell and the liquid cooling plate, so that the cell temperature and the temperature difference between the cell drop 1-2℃ will be greatly conducive to the battery thermal management system.

Hanast new materials focus on silicone adhesives and new material research and development, production for more than 10 years, has a large number of independent intellectual property rights of domestic and international leading technology, the main products mostly from independent research and development of core technology, scientific research achievements into industrial production capacity, is the domestic electronic industry adhesive industry varieties of rich enterprises.

Home

Home

Adhesive sealing silicone for automobile lamps

Adhesive sealing silicone for automobile lamps  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address