Application of adhesives in photovoltaic industry

Nov 14,2022

Nov 14,2022

Hanast

Hanast

There are many kinds of adhesives used in the photovoltaic industry, but most of them are required to adapt to the weather resistance of photovoltaic power plants, ultraviolet resistance, high temperature and humidity resistance. There are roughly the following types:

1. Bonding and sealing of laminated parts and frame

The frame and laminated parts shall be closely matched and firmly connected. The laminated parts and the frame are connected continuously and with high strength through adhesive. The bearing capacity and overall rigidity of the solar cell module are greatly improved, and the stress distribution is more uniform; The cured adhesive layer has good elastic deformation ability to adapt to the thermal deformation and external force deformation of solar cell module in use.

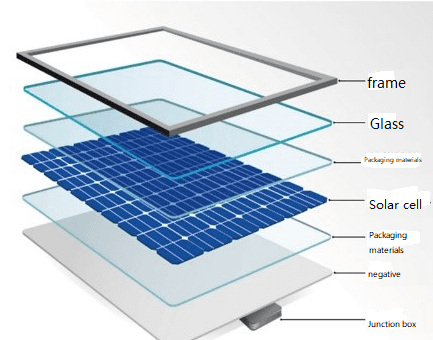

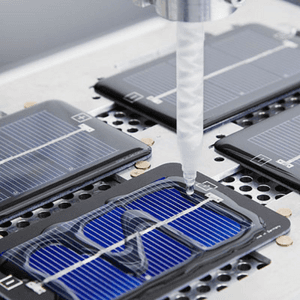

2. Packaging of battery slice, glass and backplane

Glass, battery chip and backplane materials need to be packaged by adhesive. This adhesive layer should not only provide good electrical insulation performance, but also have the following characteristics: high light transmittance; UV stability (no yellowing); It has certain elasticity, so that the battery will not crack under thermal deformation and external force impact.

3 Bonding of junction box

After the solar cell module is packaged, the junction box and the backplane need to be bonded together by adhesive. This requires that the adhesive has a good adhesion performance to various backboards and junction boxes. In order to ensure that the junction box will not fall off from the backplane even after long-term aging under local stress, the adhesive is required to have good tear resistance and aging resistance.

4 Potting of junction box

The insulation performance of the components in the junction box is required to be very high. Under abnormal working conditions, the solar cell module will have a large amount of current passing through the bypass diode and make it hot. In order to improve the heat dissipation and insulation performance of the junction box, potting glue is required to achieve the function of moisture resistance and earthquake resistance.

5 Technological bonding of silicon rod cutting

Silicon rod cutting is a key part in the manufacturing process of solar photovoltaic cells. The process is used for processing solid silicon ingots of single crystal silicon or polycrystalline silicon. The wire saw first cuts the silicon ingot into squares and then into very thin silicon chips. In this process, adhesive is required to bond silicon rod and glass, mainly epoxy adhesive.

Home

Home

Solar lamp glue solution

Solar lamp glue solution  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address