Addition silicone gel

Apr 03,2024

Apr 03,2024

Hanast

Hanast

Introduction to addition silicone gel:

The organosilicon gel is a kind of liquid silicone rubber and soft silicone rubber with a hardness below 0. Component A is silicone rubber, and component B is the platinum catalyst, namely a curing agent. When they are mixed, they will be cured into a super soft silicone rubber elastomer. It uses an environmentally friendly and non-toxic material, which is an additive organic silicone.

Additive silicone gel Application:

According to the use, there are two categories of medical silicon gel and encapsulated silicon gel. The former medical silicon gel is mainly used to produce silicone medical pads, silicone pillow pads, silicone breast pads, silicone breast implants, silicone bras, and other human products; The latter encapsulating silicon gel is mainly used for sealing, waterproofing, and fixing of electronic products such as insulation of electronic accessories, circuit boards and electronic components.

Characteristics of addition silicone gel:

1. Silicon gel is a low viscosity and viscous gel-like two-component addition organic silicon gel, which can be cured at room temperature or by heating, with the characteristics that the higher the temperature, the faster the curing;

2. This product does not produce any by-products during the curing reaction

3. Suitable for producing various medical gaskets, and human body gaskets, as well as insulation of electronic components, sealing of electronic products, electronic sealing, waterproofing, and fixation;

4. Fully comply with the requirements of the EU ROHS Directive.

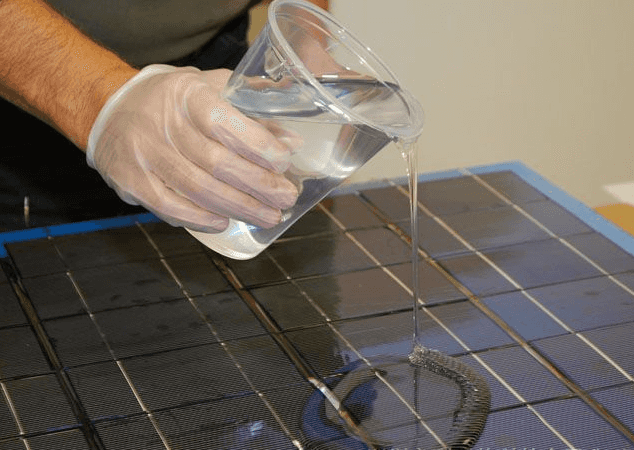

The application process of addition silicone gel:

Before mixing, first thoroughly stir component A and component B in their respective containers.

When mixing, the weight ratio of component A to component B should be 1:1.

3. Defoaming can be performed as needed during use. Mix the mixture of A and B evenly and place it in a vacuum container. After defoaming at 0.08MPa for 5 minutes, it can be poured and used.

4. For additional molding silicone gel, the temperature given in the technical parameter table shall be maintained before and after curing during use, and the corresponding curing time shall be maintained. If the application thickness is thick, the curing time may exceed. It can be cured at room temperature or by heating. The curing speed of adhesive is affected by the curing temperature, and it takes a long time to cure in winter. It is recommended to use the heating method for curing, curing at 80-100 ℃ for 20 minutes, and generally taking about 8 hours to cure at room temperature.

Home

Home

Application of LED Underwater Lamp Heat Dissipation

Application of LED Underwater Lamp Heat Dissipation  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address