Characteristics And Curing Mechanism Of Silicone Encapsulant

Oct 25,2022

Oct 25,2022

Hanast

Hanast

Two curing methods, characteristics and curing mechanism of silicone encapsulant

One of the curing methods of silicone potting glue is room temperature curing, and the other is heating curing; as to which curing method to choose depends on the specific situation. Let's take a look at these two curing methods together!

When the room temperature is 20-25°C, the normal temperature curing potting glue operation time is generally 20-30 minutes, and the curing time is 6-8 hours. When curing at 50°C, the curing speed is 4-6 hours, when curing at 100°C, the curing speed is 1-2 hours, and when curing at 150°C, the curing speed can be accelerated to 30-60 minutes. When using elevated temperature curing, it should be noted that too fast curing will lead to poor automatic foam removal effect, so if there is no special curing requirement, please use room temperature curing method.

Features of silicone encapsulant

1. It has excellent temperature resistance range and can be used for a long time at -60℃~200℃.

2. No heat absorption or exotherm during curing, no shrinkage after curing, and good adhesion to materials.

3. It has excellent electrical properties and chemical stability, and has good water resistance, ozone resistance and weather resistance.

4. After the electronic components are potted, it can play the role of moisture-proof, dust-proof, anti-corrosion and shock-proof, and improve the performance and stability parameters.

5. Excellent thermal conductivity, its thermal conductivity is more than 4 times that of general rubber.

6. Easy to use, simple coating or potting process, and can be cured at room temperature.

Curing mechanism of silicone encapsulant

Silicones can utilize two distinct bonding mechanisms: mechanical and chemical. Mechanical bonds are physical bonds that rely on surface roughness, wetting and penetration. Surface cleanliness is important for mechanical bonding, and the substrate is required to be relatively free of impurities, plasticizers and oils. Chemical bonding occurs by catalyzing the reaction between the binder and the substrate.

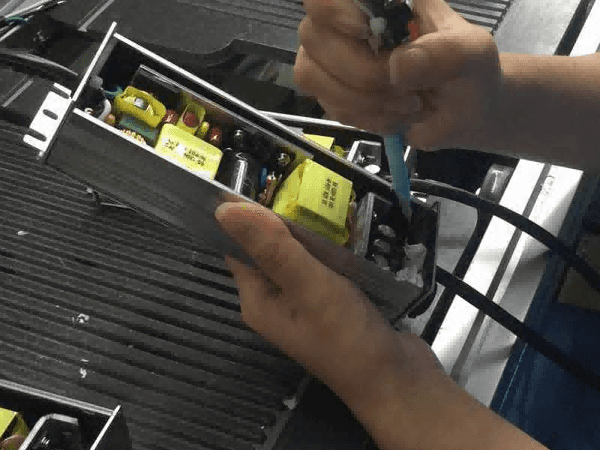

Potting compounds are protective materials designed to fully implant electronic components and circuits. They are especially used to isolate circuits from very harsh environments of use and to provide high voltage insulation for high voltage circuits, thus protecting joints from thermal and mechanical stress.

Silicone encapsulants are typically used for thick layers. A growing number of silicone encapsulants are self-adhesive, and when cured heated to above 100°C, they bond well to many common substrates. Other materials need to be primed first to get a full bond. Testing (or accelerated testing) under conditions close to actual use is critical for predicting long-term performance in any application. Like most silicone products, potting compounds offer a variety of options. They offer high shear strength, optical clarity, flame retardancy or extreme low temperature performance. Certain materials provide thermal conductivity or volatility, while others are used to meet UL specifications.

Home

Home What Is RTV Silicone Glue?

What Is RTV Silicone Glue?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address