Application advantages of silicone materials in new energy vehicle cables

Apr 11,2023

Apr 11,2023

Hanast

Hanast

Silicone material is one of the indispensable and important materials in automobile manufacturing. It can not only optimize the manufacturing process of automobiles, but also improve the performance and safety of automobiles. It has been widely used in various parts of automobiles, such as airbag coating , power transmission seals, gaskets, hoses, windshield linings, automotive engine seals, ignition wires and coil sheaths, automotive turbocharger tube cooling tubes, sealing and protection of automotive components, high-voltage cables and wiring harness seals, etc. .

With the increasingly tense global energy sources and the increasingly serious problem of environmental degradation, energy conservation and emission reduction have made new energy vehicles the development direction of the global automotive industry. New energy vehicles include hybrid electric vehicles (HEV), pure electric vehicles (BEV), fuel Battery vehicles (FCEV), hydrogen engine vehicles, gas vehicles, alcohol ether vehicles, etc.

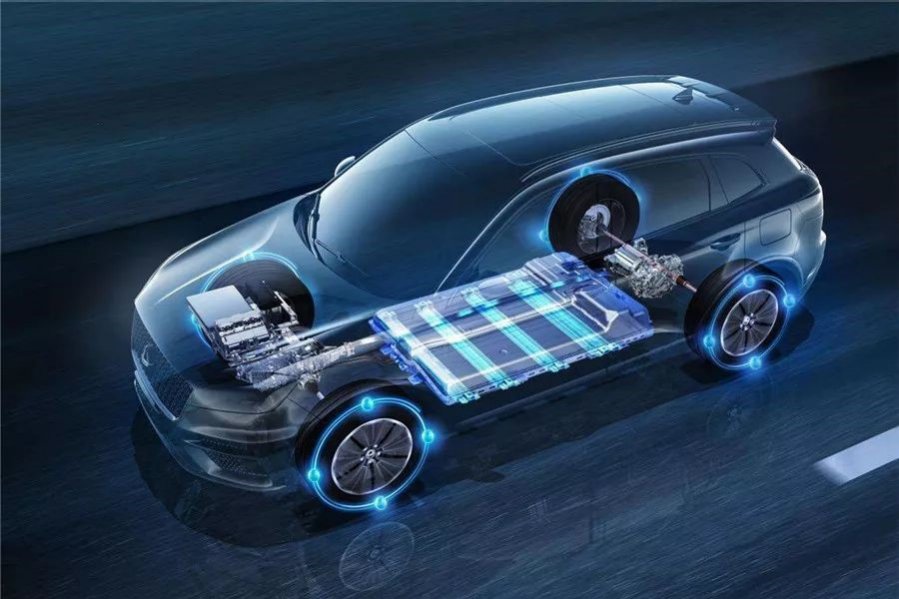

Compared with traditional fuel vehicles, hybrid and pure electric vehicles add many high-voltage accessories, such as power batteries, high-voltage distribution boxes, drive motors, motor controllers, etc., which also put forward new requirements for automotive cables. Since these cables are arranged in the engine and chassis areas of the front cabin, the temperature is high and the space is small, so the cables need to be soft, have a small turning radius, and have good high and low temperature resistance; secondly, the road conditions are complex, and the cables must have good wear resistance and high mechanical strength; In addition, the vehicle speed is sometimes high and sometimes low, especially in harsh working conditions such as full-load climbing, and the instantaneous high current requires the cable to have a short-term overload capability.

In summary, new energy vehicle cables must have: good electrical insulation performance; thermal stability, weather resistance; corrosion resistance, oil and hydrophobicity, excellent flame retardant performance; superior comprehensive mechanical properties, high flexibility and high tear resistance crack and so on.

At present, the insulation materials for automotive power cables include cross-linked polyolefins and thermoplastic elastomers. Among them, the cross-linked polyolefin material can withstand heat up to 150°C, but the cable of this material is relatively hard, it is inconvenient to install in the narrow car body space, and it needs radiation cross-linking, the process is complicated, and it is not suitable for large-section cables. However, the heat resistance of thermoplastic elastomer materials does not exceed 125°C, and the temperature grade used for power cables is relatively low, and cables made of thermoplastic elastomer materials may be at risk of cracking after long-term use.

Silicone rubber has high and low temperature resistance, ozone resistance, weather resistance and excellent electrical insulation; silicone rubber wire has a large carrying capacity, saves conductor cross section, and can meet the requirements of long-term full-load operation; it can meet the requirements of fire resistance by adding flame retardants; it has High flexibility, easy to install in limited space; high tear-resistant silicone rubber, trouser tear can reach 25N/mm. Therefore, silicone rubber materials can make up for their shortcomings while combining the advantages of cross-linked polyolefin and thermoplastic elastomer materials, and silicone rubber can reduce vehicle weight and carbon dioxide emissions. It is a high-quality choice for automotive power cables.

Among the many downstream application fields of organic silicon, energy-saving and environmental protection industries such as photovoltaics and new energy have been supported by policies to grow rapidly; at the same time, the rise of ultra-high voltage and ultra-high voltage power grid construction, 3D printing, smart wearable devices and other emerging fields have promoted Silicon market growth. In addition, organosilicon materials are irreplaceable for major national projects. They are mainly special organosilicon materials with high reliability, high stability and high performance. Although the amount is not large, there are many types and high technical requirements. The future development prospect is optimistic.

Home

Home

The difference between Addition-Type Potting Compound and Condensation Potting Compound

The difference between Addition-Type Potting Compound and Condensation Potting Compound  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address