Application of silicone potting adhesive in various fields

Dec 12,2022

Dec 12,2022

Hanast

Hanast

1. Application in the manufacture of transportation

Silicone sealants have excellent water resistance and lubricating oil resistance, and can be used in water-based systems such as water pumps and water tanks, as well as in lubricating oil-based systems such as engines, gearboxes, cam boxes, transformers, and hydraulic systems. It is mainly used in the bonding and sealing of on-site forming gaskets and automobile engines, windshields, door and window frames, reflectors, exhaust pipes, lights, instruments, containers, carriages and other equipment susceptible to water spray.

2, The application of electricity

It has excellent insulation performance and low thermal expansion coefficient; waterproof performance can make the cured colloid effectively prevent condensed water from entering; corrosion resistance can ensure long-term work in acid and salt environments; excellent aging resistance makes its service life longer As long as 50 years, it is widely used in insulation, moisture-proof sealing, environmental protection and anti-corrosion, encapsulation and bonding of cable accessories, etc.

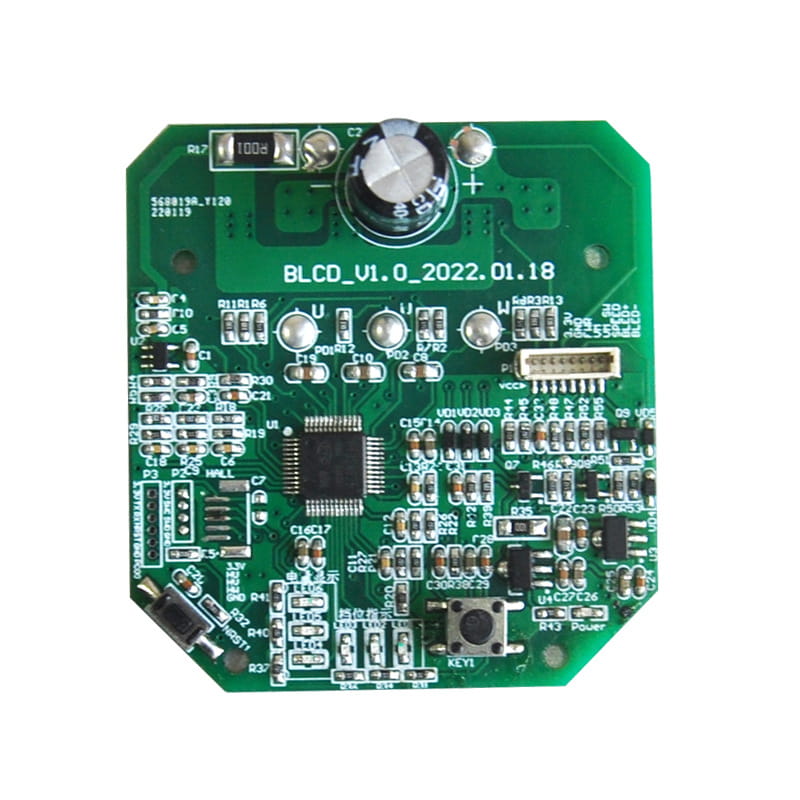

3. Application in electronics and radio industry

Room temperature curing silicone sealants are widely used in encapsulation, potting, bonding, impregnation and coating in this field, and are used for potting integrated circuits, micro-film components, thick film components, electronic assemblies or complete machines. The internal components are clearly visible, allowing accurate measurement of component parameters.

4. Application of silicone potting glue in automotive electronics

The potting glue is used on various control modules, and the components are integrally and generally potted to meet the basic requirements of moisture-proof, anti-fouling, and anti-corrosion. Silicone is used in automotive electronic devices: adhesives and sealants, potting adhesives, gels, insulating coatings, thermally conductive adhesives and other materials. These materials are used to protect engine control modules, ignition coils and ignition modules, power system modules, braking system modules, exhaust emission control modules, power supply systems, lighting systems, various sensors, connectors, etc. The use of silicone potting compound can reduce stress and withstand high and low temperature impact. For high-power control modules, thermally conductive potting compound is used to achieve the function of heat dissipation. Organosilicon potting materials are widely used in components such as wiper controllers and power system modules. Potting of HID (High Intensity Discharge) lamp modules is a typical application. The HID module contains the igniter and converter. The potting compound used must have good bonding properties and excellent dielectric properties, be able to prevent dust and water seepage, and provide sufficient insulation protection; the potting compound must be relatively soft to prevent the solder joints from falling off; There are some heating elements inside the module, so the potting compound needs to have a certain heat conduction effect.

5. Application of organosilicon materials in power supply industry

Due to the unique properties of silicone materials, excellent properties such as moisture resistance, water repellency, electrical insulation, high and low temperature resistance, and chemical stability, some varieties also have radiation resistance, oil resistance, and solvent resistance, as well as stable physical and chemical properties. In recent years, it has been widely developed and applied in the field of power supply industry, and it is a typical technology-intensive and high value-added product. With the continuous development of high-tech industries, in order to ensure the stability and durability of the performance of power supply equipment in various industries, the elimination of environmental factors (moisture, salt spray, dust, vibration, heat, etc.) The influence of the equipment leads to the reduction of the reliability of the equipment, which puts forward stricter requirements for the power supply industry.

6. Application of silicone sealant in building energy saving

The application of silicone sealants in building doors, windows and curtain walls mainly includes three aspects: secondary sealing of insulating glass, curtain wall structure, weather-resistant sealing and waterproof and weather-resistant sealing of doors and windows. The quality of silicone sealant not only affects the safety of the entire building door, window and curtain wall structure, but also affects whether the building meets the requirements of energy conservation and environmental protection

Home

Home

What is organic silica gel? How should silica gel be used?

What is organic silica gel? How should silica gel be used?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address