Classification and Application of Electronic potting compound

Sep 08,2023

Sep 08,2023

Hanast

Hanast

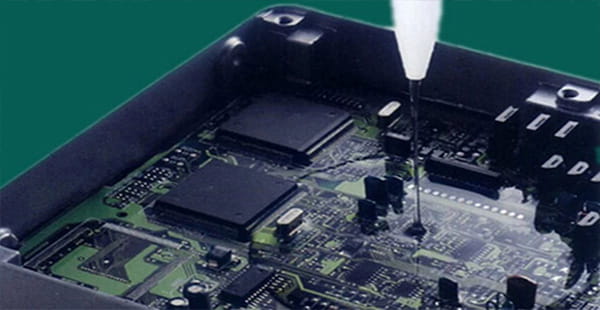

With the continuous improvement of adhesive research and development level and the development of the electronic industry, various products have been launched for the electronic industry adhesive. Now the editor will talk about electronic potting compound. Electronic potting compound belongs to the liquid state before solidification, has fluidity, and can be fully poured and covered on the product. The viscosity of the adhesive varies depending on the material, performance, and production process of the product.

The potting compound needs to be fully cured before it can achieve its useful value. After curing through the potting process, it can reduce the impact of external environmental conditions on components, ensure their good operation in standard working environments, and improve the normal stability and service life of components. It can effectively prevent water and moisture, dust, insulation, heat conduction, confidentiality, corrosion, temperature resistance, and shock. There are also various types of electronic potting adhesives, and different types of electronic potting adhesives have different usage methods and functions, which need to be determined according to needs.

What are the classifications of electronic potting compound? There are many types of electronic potting compound, mainly including thermal conductive potting compound, epoxy resin potting compound, organic silicon potting compound, polyurethane potting adhesives, and LED potting adhesives. These five types of electronic potting adhesives are not the same in type, composition, and performance after curing, but they can all be used in electronic production and manufacturing, playing a role in sealing, waterproofing, heat dissipation, fixation, and impact resistance.

There are many types of electronic potting compound and they are widely used in various scenarios. They can be used for high-power street light power supplies, power modules, HID light power modules, solar junction box sealing protection, LED electronic display screens, LED electronic sealing adhesives, circuit board sealing, power cord bonding, LED, LCD high-power lights, mobile phones, power boxes, ultra-thin computers, game consoles, digital cameras, airport runways, etc.

Home

Home

What application properties will be affected by the curing shrinkage rate of organic silicon potting compound

What application properties will be affected by the curing shrinkage rate of organic silicon potting compound  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address