Common problems and solutions of using RTV silicone gel dispensing

Feb 09,2023

Feb 09,2023

Hanast

Hanast

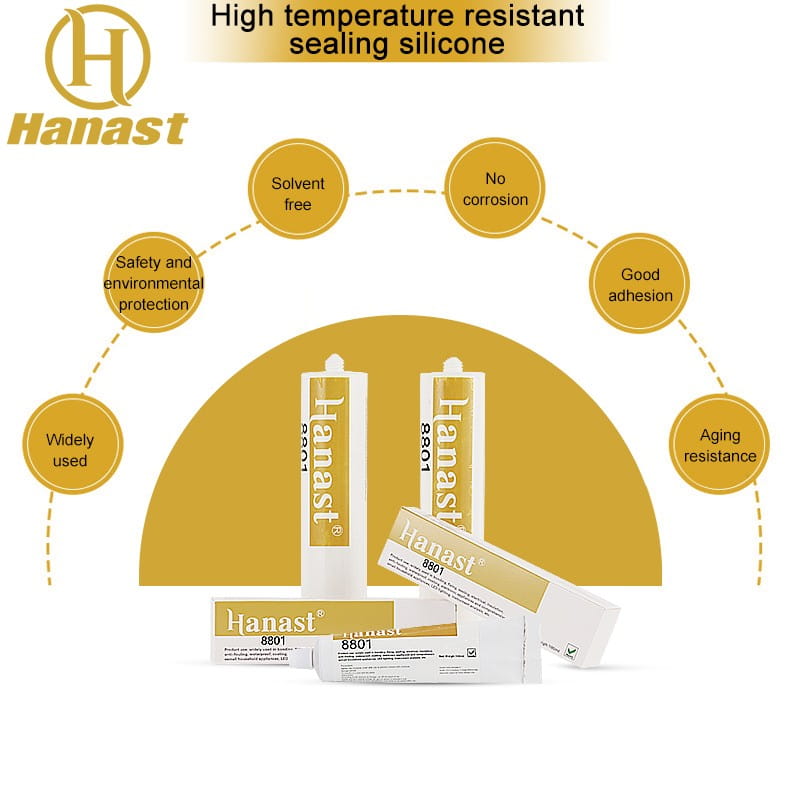

1. The sealed waterproof silicone RTV specified by the customer is a kind of silicone rubber that will become vulcanized at room temperature.

RTV is processed with a dispensing machine. After curing, the glue is elastic. The surface also has the properties of heat and cold resistance, aging resistance and insulation. The inside of the glue has the properties of moisture resistance, shock resistance, corona resistance and electric leakage resistance. It has excellent product adhesion, surface yellowing resistance, moisture resistance and other properties, but it will be contaminated in many ways in the outdoor. Below I list the problems that occur when the glue is dispensed with the dispenser.

2. After the dispensing machine completes dispensing, the outermost layer of glue-cured silica gel will appear limp wrinkle.

The reason is that the outer surface of silica gel is solidified first, and then the inner surface is deformed during curing, and the inner surface is shortened, resulting in wrinkling of the outer skin. This is related to the characteristics of RTV silica gel used, probably due to the addition of solvent-based silicone resin.

After the glue is applied, you can see layers of curved offset printing. There are two situations that can lead to this situation. One is that there is a problem with the glue used, and the mixed use of two different media of glue will occur. The second is that the glue in the glue is not smooth, or there are bubbles inside. Because the silica gel glue is too sticky, the bubbles will be wrapped by the glue after the glue comes out, resulting in layers of offset printing.

After curing, the outer surface of the silicone glue is not full enough, and there are line marks. This problem is caused by the lack of smoothness of the glue outlet. Just replace the needle or clean the glue flow channel.

Home

Home

What is [RTV silicone glue]? What are the performance characteristics of RTV silicone rubber glue?

What is [RTV silicone glue]? What are the performance characteristics of RTV silicone rubber glue?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address