How to handle silicone mold sticking?

Mar 07,2024

Mar 07,2024

Hanast

Hanast

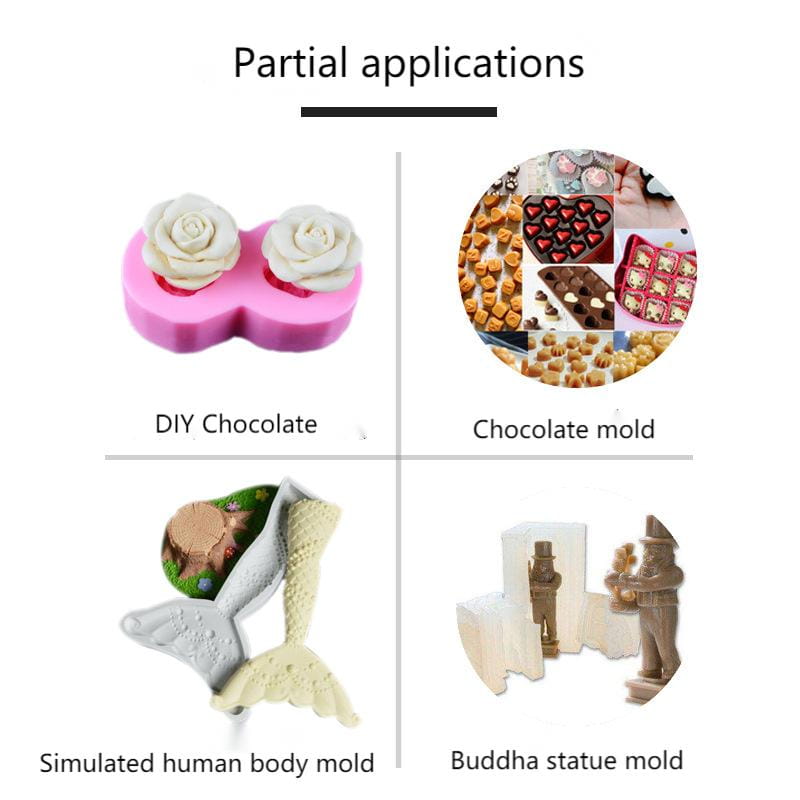

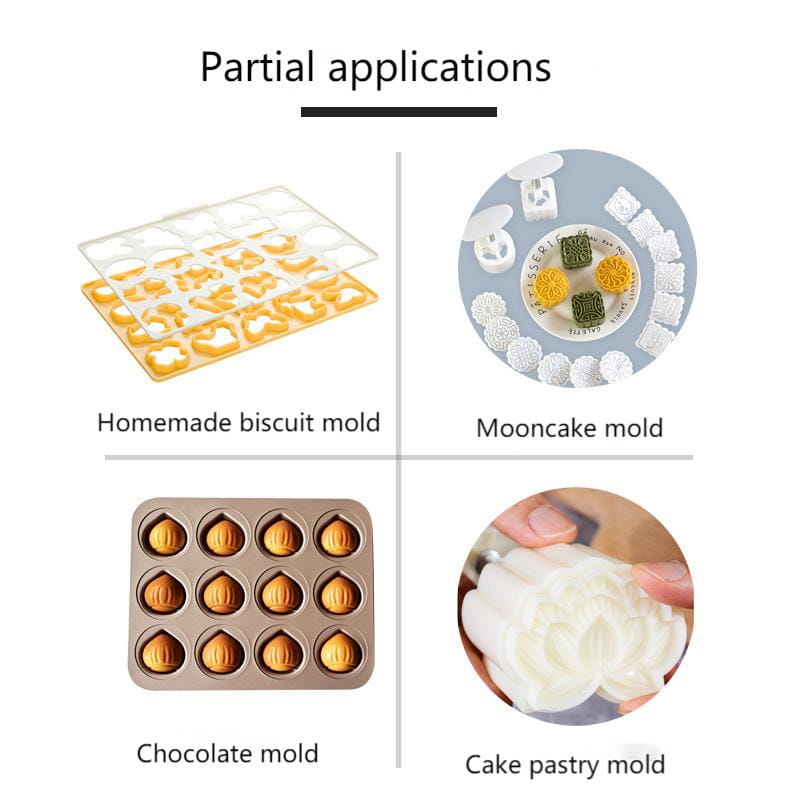

Silicone molds can be used for mass production of cement, gypsum, cultural stones, candles, soap, resin, food, prosthetics, human skin masks, models, and other products. During the production process, both mold opening and production must undergo a demolding process. However, during this process, silicone mold sticking occurs, which means that it is difficult to separate the mold from the product. In this case, destructive methods need to be used to solve the problem and classify the mold from the product, which can lead to product deformation or tearing of the silicone mold, resulting in a win-win situation. How to handle silicone mold sticking, how to ensure product integrity, and how to prevent silicone mold sticking?

Let's first analyze why silicone molds tend to stick. The main reason is due to the raw materials used in the products. The degree of demolding varies depending on the material used. Cement, gypsum, and cultural stone products are relatively easy to demold due to their rough surface and large pore size. Candles and soap types are also difficult to de-mold, with resin and silicone products being more difficult to de-mold due to their small surface pore size and smoothness, resulting in a strong adhesion with silicone. When making molds or mass production of this type of product, the method of preventing mold silicone sticking can be used by uniformly spraying release agents on the mold type or mold. There are several methods to obtain mold release agents:

① Purchase mold-specific release agents online or offline;

② Pharmacy purchases of Vaseline;

③ Use soap water or detergent water. When using the release agent, it is necessary to evenly spray it on every corner and gap of the mold or mold. When using soap water or detergent water, the moisture must be dried. At this time, a hair dryer can be used to blow dry before proceeding with the next step. Spraying release agents can not only prevent silicone molds from sticking but also prevent the occurrence of non-curing at the contact area between the mold and the mold during the mold opening process.

In addition to product materials, there is also the molding process to avoid silicone mold sticking. When making silicone molds, the mold should be cleaned and polished. During the mixing process, the silicone and curing agent must be mixed evenly, and attention should be paid to the details during operation. Otherwise, if some parts do not solidify, they will become silicone mold sticking. Another thing is to choose the appropriate mold opening method for the product structure.

Home

Home

How many times can silicone flipping molds be used

How many times can silicone flipping molds be used  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address