How to remove the bubbles generated after stirring liquid silicone?

Dec 14,2023

Dec 14,2023

Hanast

Hanast

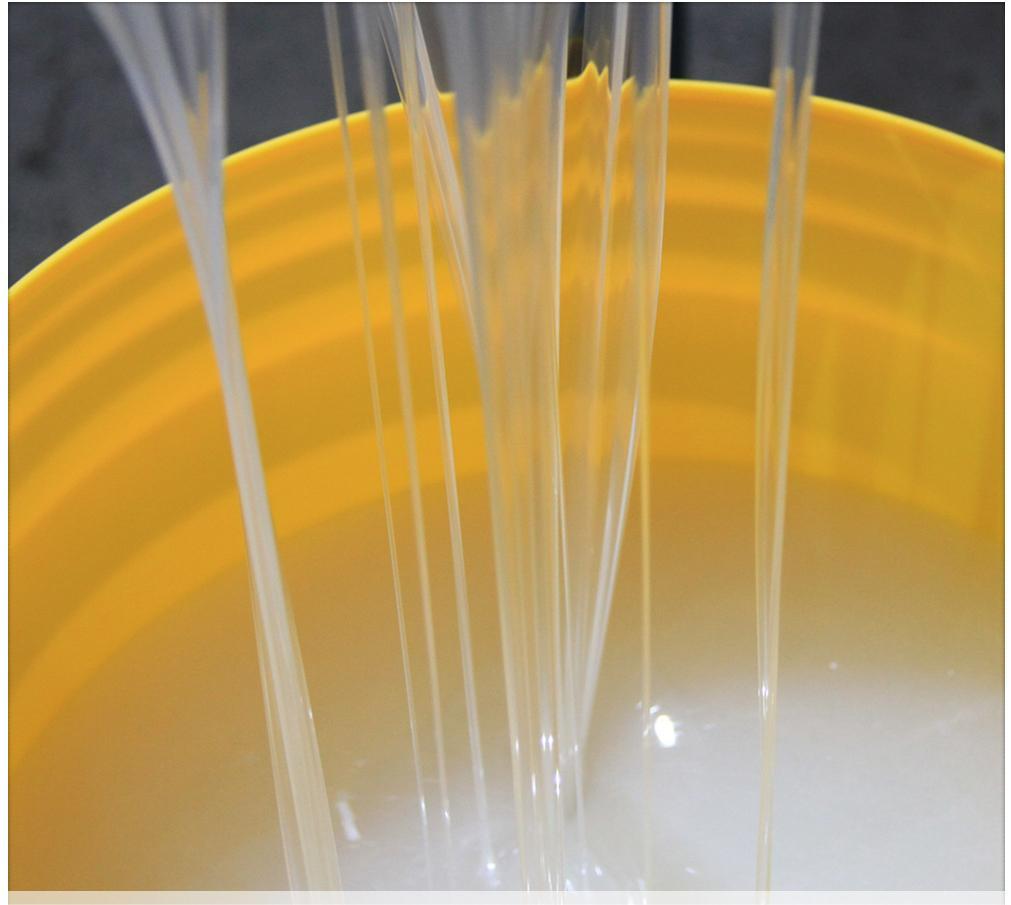

Many people will find a problem when dealing with liquid silicone products, that is, there are many silicone bubbles that cannot be drained out, resulting in products that are not beautiful enough and cannot achieve the expected results, causing huge losses. Below, Hanast will teach you how to reduce the bubbles generated after stirring liquid silicone. Let’s learn more together.

1. If it is a condensation liquid silicone product, you can add less curing agent and extend the operating time to achieve natural foaming effect.

2. When the same amount of curing agent is added, the temperature of the operating space can be lowered, thereby prolonging the curing time, making it easier to remove bubbles.

3. When stirring liquid silicone products, please try to stir in the same direction so that there are relatively few bubbles.

4. Manufacturers are required to reduce the viscosity of silica gel during the production process so that it has better fluidity and easier air bubble discharge. However, if the viscosity is too low and more silicone oil is added, the performance of the product will also deteriorate.

5. A more practical method is to use a silicone vacuum machine. No matter how viscous the liquid silicone product is, it can still be easily passed through a vacuum machine to remove all the air bubbles inside.

Home

Home

Liquid silicone as soft as jelly

Liquid silicone as soft as jelly  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address