How to Select the Best Potting Adhesive with High Thermal Conductivity

Jan 07,2023

Jan 07,2023

Hanast

Hanast

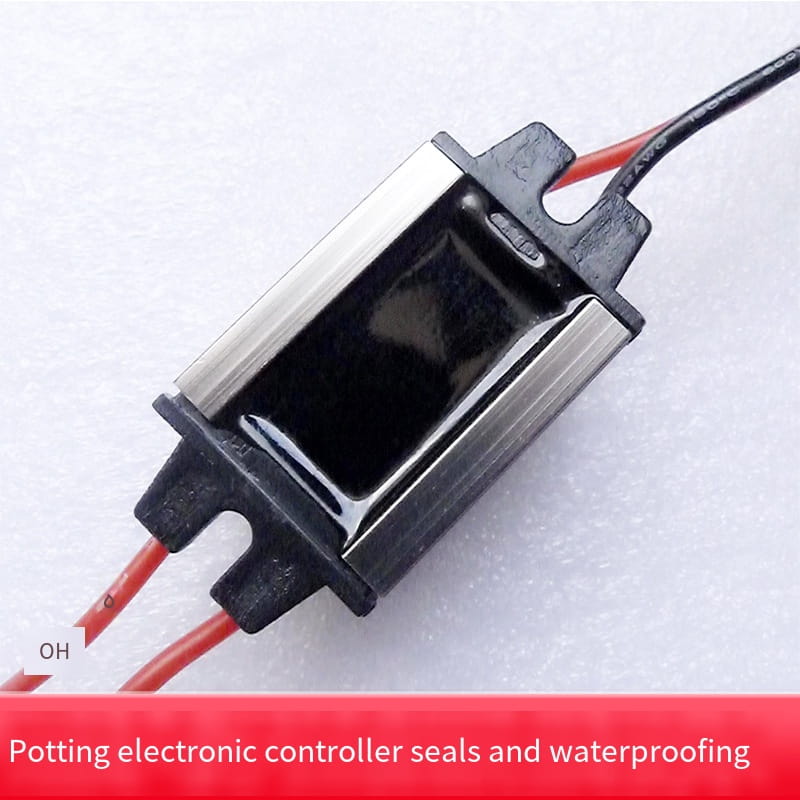

With the miniaturization and high efficiency of electronic and electrical appliances, the heat dissipation capacity of heat dissipation materials is constantly challenged. The more common is the rapid charging of mobile phone PD, which takes 5 minutes to charge for 2 hours. The charging speed is very fast. The problem is that the heat generated is large, and the heat needs to be transferred quickly. Otherwise, the service life is very short, and the temperature is too high, which is prone to fire. Therefore, the rapid charging of PD also begins to use heat conductive potting glue for heat dissipation. Therefore, as a commonly used heat dissipation material, the thermal conductivity of the thermal conductive potting compound is constantly improving with the improvement of the market application requirements. The commonly used potting compound was 0.6W before, but it was later mentioned as 0.8W. Now it has increased by 1.5W. It is easy to improve the thermal conductivity of the thermal conductive potting adhesive, but it is easy to use and anti settling after improving the thermal conductivity, which will greatly test the R&D personnel of the manufacturers of high thermal conductive potting adhesive. Analyze how to select high thermal conductivity potting sealant from the following dimensions.

1. Viscosity and fluidity. Viscosity is a very important assessment index, which is related to the fluidity of high thermal conductivity potting sealant. The silica gel base material is colorless transparent liquid. After curing, the thermal conductivity of silica gel is weak, and the thermal conductivity is only about 0.2W. To improve the thermal conductivity, you need to add thermal conductivity powder. The more you add to the base material, the higher the thermal conductivity, and slowly it will become paste. If the viscosity is not controlled, the viscosity (mPa ▪ s) It is very high, often tens of thousands. If it is too high, it will flow slowly, or even not move, and can not effectively flow into the gaps of components. Especially for small appliances, once it is not filled in place, it is full of air bags. Glue filling is equivalent to nothing, and the heat inside cannot be transferred out.

High thermal conductivity and excellent fluidity

2. Anti settling. It is a very normal phenomenon for high thermal conductivity potting compound to settle. After adding heat conduction powder, the base material is silicone oil. The density of heat conduction powder is higher than that of silicone oil. The oil is heavy and the powder is light, so it is easy to settle. Therefore, whether the potting compound with high thermal conductivity is good depends on how long it starts to settle and whether it can be stirred again after settling.

3. After the above two indicators are well controlled, it is necessary to see whether the thermal conductivity is up to standard. Some companies have abandoned some other indicators in order to do a good job in viscosity and anti settlement. The more obvious is the thermal conductivity, which has a virtual standard phenomenon and is quite different from the actual thermal conductivity.

The comprehensive viscosity of 1.5W high thermal conductivity potting adhesive developed by our company is 4600 mPa ▪ S, with a density of 2.4 g/cm3, which is very resistant to sedimentation. Even after sedimentation, it can easily stir up. If you are interested, you can go and find out.

Home

Home

Typical uses and operation methods of RTV adhesive

Typical uses and operation methods of RTV adhesive  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address