Introduction to Common Applications and Advantages of Adhesives in Home Appliance Products

Sep 05,2023

Sep 05,2023

Hanast

Hanast

With the continuous development of the home appliance industry, the market has increasingly high requirements for the aesthetics and functionality of home appliances. In many cases, consumers focus not only on the overall quality of products, glue for appliances but also on more details. electric appliance adhesive Adhesive, as an important auxiliary material for household appliances,appliance silicone sealant is being increasingly widely used. Choosing appropriate adhesives and using them reasonably can not only meet product design requirements, but also improve production efficiency of enterprises, thereby effectively reducing costs.

Compared to traditional bonding materials, adhesives have the following advantages in bonding some parts of household appliances:

1. Able to bond different materials without damaging the substrate.

2. The stress distribution of adhesives is wider and more uniform, and the strength, mass ratio, and dimensional stability of anisotropic materials are improved through cross bonding.

3. It is faster and more efficient than traditional bonding methods, and can reduce labor costs.

4. While achieving adhesive bonding, it also has sealing, filling, thermal conductivity, and conductivity properties.

5. Able to carry out special designs to enhance product aesthetics.

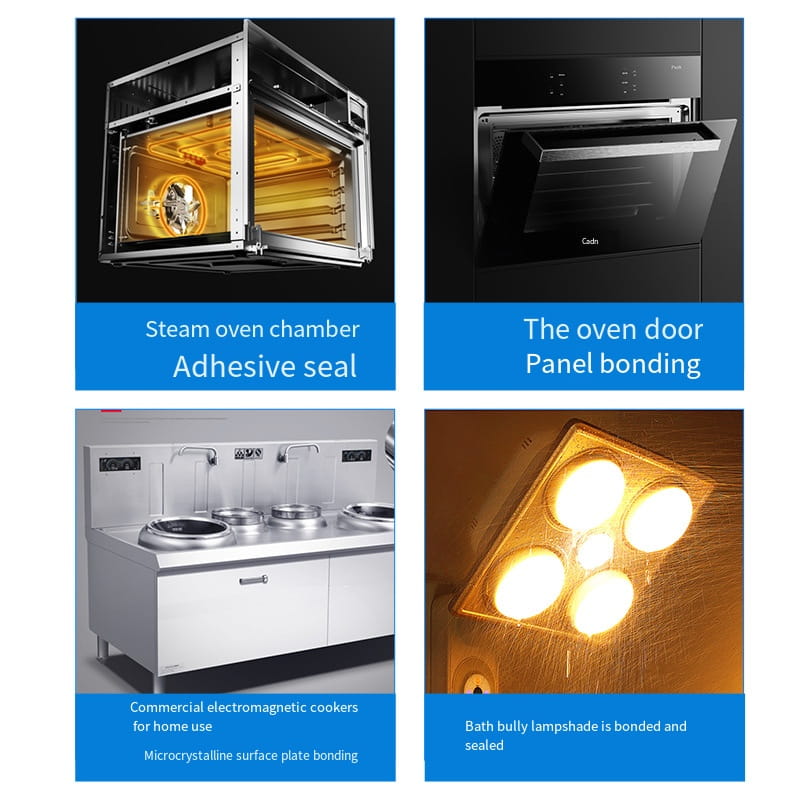

In recent years, with the continuous improvement of the quality of household appliances, some high-performance electronic adhesives have become more and more widely used. Almost every household appliance product uses adhesives in the production process. The following is an introduction to the application of adhesives in some common household appliance products.

1. Adhesives with different characteristics need to be selected according to different usage requirements for the fixation of white household appliances such as refrigerators, air conditioners, washing machines, circuit board three proofing, radiator filling, glass panel bonding, partition/storage box fixation, frame sealing, etc. For example, the protection of circuit boards in washing machines requires the use of three proofing adhesive coating, and the bonding and sealing of various plastic and metal parts require the use of hot melt adhesive. To prevent bolts from loosening, affecting production efficiency, or gasket damage that may affect future use, many manufacturers of washing machines or air conditioners use anaerobic thread locking adhesive for locking, reducing the use of gaskets and maintaining reliability for a long time.

2. The bonding and sealing of kitchen electrical products such as microwaves, electric ovens, and range hoods cannot be separated from high-temperature resistant adhesives. A transparent adhesive with fast curing, acid and alkali resistance, high temperature resistance, and water and oil resistance is required to bond between the stainless steel plate of the range hood and the tempered glass painted at home. Two component AB adhesive has a fast curing speed at room temperature, and after curing, it has high bonding strength, high temperature resistance, aging resistance, water and oil resistance, and acid and alkali resistance. It is suitable for bonding various substrates and meets its bonding requirements. At the same time, for the sake of aesthetics and reducing connection threaded holes, some products will adopt the form of overall appearance bonding.

3. Cleaning household appliance controllers such as vacuum cleaners and dishwashers require the use of potting adhesive for potting. Hoses and metal sheets need to be bonded and fixed using a series of adhesives that utilize the adhesive force generated on the surface of the object.

The adhesive application plan for different household appliances is also different. When choosing an adhesive, we need to consider the entire production process, construction rhythm, and process requirements of the product comprehensively. Some even need to modify our product formula according to specific product requirements to meet customer product usage needs.

Home

Home

Introduction to the advantages, disadvantages, and application scope of organic silicon potting compound

Introduction to the advantages, disadvantages, and application scope of organic silicon potting compound  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address