Introduction to product knowledge of thermal conductive silicone grease

Jun 09,2023

Jun 09,2023

Hanast

Hanast

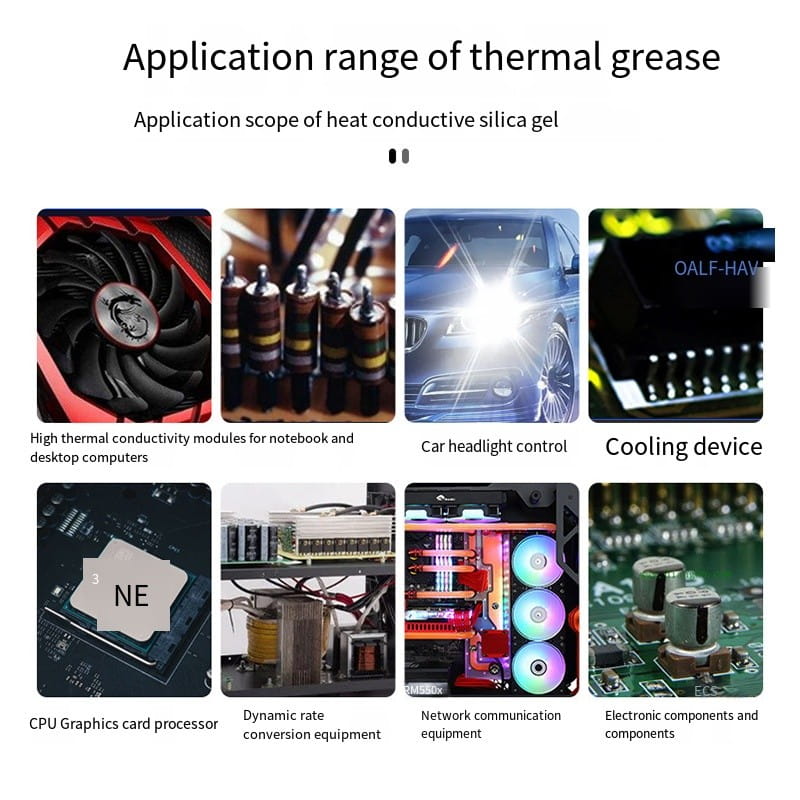

Thermal conductive silicone grease, also known as heat dissipation paste, is a paste made by using special silicone oil as the base oil, adding materials with excellent heat resistance and thermal conductivity, such as new metal oxides as fillers, and adding various functional additives through specific processes. Colors have different appearances due to different materials. It has good thermal conductivity, temperature resistance, insulation and other properties, making it an ideal medium material for heat-resistant devices. Moreover, its chemical properties are stable, and it will not produce corrosive gases during use and will not affect the metal in contact. Widely used for heat conduction and dissipation of electronic components such as power amplifiers, transistors, electronic tubes, CPUs, etc., to ensure the stability of the electrical performance of electronic instruments and meters.

The Thermal Grease is in direct contact with the radiator, forming a high gradient temperature difference at its junction. Even on polished surfaces, it is not possible to achieve full physical contact between the two surfaces. If the thermal conductive material is filled in the middle, it can be seen that it effectively reduces the temperature difference between the heat source and the radiator. To reduce thermal resistance, it is necessary to achieve complete physical contact in order to form an efficient heat conduction pathway.

The heat conduction principle of Thermal paste is to fill the gap between the CPU and the radiator, so that they can fully contact each other. The electrical appliances are more conducive to the transfer of heat energy during the working process. Therefore, the use of Thermal paste cannot be too thick. The thick silicone grease layer blocks the heat transfer, which is not conducive to the rapid transfer of heat. So, when using thermal conductive silicone grease, an appropriate amount is sufficient, not the more it is applied, the better the thermal conductivity effect.

Key properties of thermal conductive silicone grease

The thermal conductivity is one of the important indicators in the application process of thermal conductive silicone grease. Generally, users lack instruments to directly test the thermal conductivity, and the heat dissipation effect is verified through whole machine testing. However, this is a temporary effect, such as the requirement for a thermal conductivity of 1.0w/m.k, while the manufacturer provides 0.8w/m.k. From the user's whole machine testing, there may not be a significant difference, but the thermal conductivity effect may not keep up with the actual application time, Causing premature product failure; When choosing an accurate thermal conductivity coefficient, do not easily believe in theoretical values, but rather rely on actual test values. When choosing a thermal conductivity coefficient, everyone should understand more about the parameters related to the thermal conductivity coefficient, such as test area, heat flow rate, test thermal resistance, test pressure, average temperature, etc. If these parameters can be explained clearly, it indicates that the thermal conductivity of the thermal silicone grease has been strictly tested, Prevent obtaining thermal conductive silicone grease that is lower than the actual demand.

02 Consistency

Consistency is an important indicator of the operability of thermal conductive silicone grease, generally characterized by items such as fineness, viscosity, and penetration. Fineness requires that thermal conductive silicone grease be produced without particles, which can cause uneven contact surfaces and dry appearance, making it difficult to scrape flat; The higher the viscosity or lower the penetration of thermal conductive silicone grease with the same thermal conductivity, the more difficult it is to operate. Therefore, after confirming the thermal conductivity, it is necessary to compare the operability to avoid affecting production efficiency.

03 High temperature aging

To ensure the reliable application of thermal conductive silicone grease within the expected service life of the product, knowledge of the weather resistance of thermal conductive silicone grease requires understanding two aspects: firstly, what is the decay rate of the thermal conductivity coefficient of thermal conductive silicone grease after aging; Secondly, what is the volatility and oil yield after aging; Once these are confirmed, it is basically possible to confirm whether the thermal conductive silicone grease will fail prematurely during use.

Precautions for use

01

Do not use your fingers to apply heat dissipation cream, use a fingertip instead

02

Before use, first confirm that there are no foreign objects on the base of the heat sink and the surface of the device core before gently placing the heat sink on the device

03

After placing the heat sink on the device, do not rotate or translate the heat sink, otherwise it may cause uneven thickness of thermal grease between the heat sink and the device

04

In terms of storage, do not place it in direct sunlight. Store it in a cool and ventilated place. After opening and using it, try to use it all at once. If there is any residue, it must be sealed and stored

05

In terms of safety, contact with skin and eyes should be avoided. If it accidentally enters the eyes, please immediately wash them with clean water. If necessary, see a doctor, wipe off contact with skin with a dry towel, and wash thoroughly with soap

Home

Home

Is thermal conductive silicone grease really useful? How to choose thermal conductive silicone grease?

Is thermal conductive silicone grease really useful? How to choose thermal conductive silicone grease?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address