Reasons and solutions for cracking of epoxy resin potting adhesive

Mar 20,2024

Mar 20,2024

Hanast

Hanast

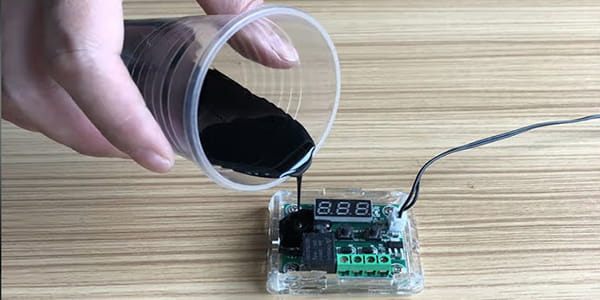

The epoxy resin potting adhesive is widely used in many fields due to its superior performance, but the defect of easy cracking in low-temperature environments has a certain impact on the quality of products and the safety and stability in use, which has always been an urgent problem that needs to be solved in sealing work. So what is the main reason for the cracking of epoxy resin potting adhesive, Is there a solution? Today, the HANAST editor will provide you with a specific analysis.

Analysis of cracking causes:

Due to factors such as formula design, product structure design, and sealing process, epoxy resin potting adhesive will generate significant internal stress during the curing process. Under the action of internal stress, different degrees of defects and fine crack propagation in the potting adhesive will cause cracking. So, the presence of internal stress is the fundamental cause of cracking in sealing materials.

Solution:

Reasonable design of the structure of epoxy resin potting products can effectively reduce the internal stress in the sealing material. The design of embedded parts and sealing molds in epoxy resin sealing can refer to the following principles:

1. The size and shape of the sealing mold should be conducive to the free shrinkage of the sealing material and the dispersion of stress.

2. The embedded parts and sealing molds should avoid sharp corners, sharp edges, or parts with sharp angle changes, and should be circular as much as possible. Because the stress generated around the circular area is uniform and consistent, it is easy to cause epoxy resin cracking at the corners due to stress concentration.

3. The number of inserts should be minimized to avoid stress concentration.

4. A flexible transition method should be adopted, which is to design an elastic buffer layer to alleviate the impact of internal stress on the sealing body.

By using the above methods, the internal stress in epoxy resin potting adhesive parts can be greatly reduced, thereby improving their resistance to low-temperature cracking performance.

Home

Home

What are the main factors to consider when choosing a suitable potting adhesive?

What are the main factors to consider when choosing a suitable potting adhesive?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address