Selection scheme for epoxy potting adhesive for capacitor encapsulation

Mar 20,2024

Mar 20,2024

Hanast

Hanast

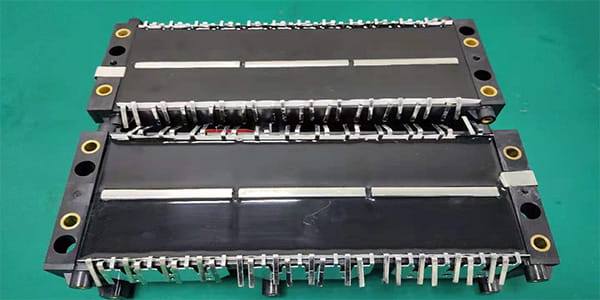

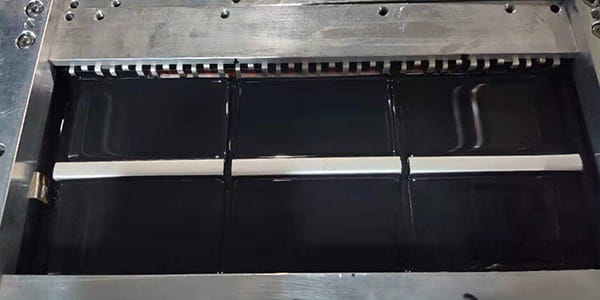

The main function of capacitors is known to be energy storage, and they are widely used in the automotive electronics industry. Therefore, the protective effect of capacitors on their use directly affects the usage of automotive power sources. So what quality level of epoxy potting adhesive can meet the protection requirements of capacitors in the automotive industry? How to choose a reliable epoxy potting adhesive? Today, the editor will share with you the process of performance selection analysis and adhesive solutions for practical application products.

Firstly, it is necessary to investigate the factors that affect the normal operation of the capacitor, such as water, moisture, corrosive substances, and discharge phenomena. Therefore, the purpose of applying epoxy potting adhesive is to completely seal and protect the capacitor, avoiding contact with water, moisture, corrosive substances, etc., and also to avoid leakage discharge phenomena. Further analysis shows that to prevent external factors from affecting the capacitor, the epoxy sealing adhesive must meet the requirements for use in harsh environments, resist external environmental influences without delamination or cracking, and effectively protect the capacitor.

So the key objectives of the selection plan for epoxy potting adhesive for capacitors are to prevent cracking, delamination, and insulation. The key projects involved include double 85 testing for more than 1000 hours, cold and hot impact for more than 1000 hours, resistance to electrochemical corrosion, and insulation strength. To achieve the above projects, the expansion and contraction coefficients of epoxy potting adhesive must be very small to meet the problems of delamination and cracking caused by the continuous expansion and contraction of the colloid. So first, we need to solve the problems of the expansion coefficient and shrinkage rate of epoxy potting adhesive.

Based on the investigation and analysis of the comprehensive application of capacitors and epoxy potting adhesive mentioned above, when choosing epoxy potting adhesive for capacitors, the first step is to understand the volume expansion and contraction of the epoxy potting adhesive. The second step is to understand the water absorption rate of the colloid. If the water absorption and moisture absorption are strong, it will affect the internal capacitors over time. Epoxy sealing adhesive can be divided into amine and anhydride types. Generally, the anhydride type has better moisture absorption than the amine type. The third step is to choose an epoxy sealing adhesive with relatively low internal stress, which can resist the hydrogen and sulfide produced by electrochemical corrosion and cause cracking problems.

I believe everyone has a certain understanding of the breakthrough points of using epoxy potting adhesive for capacitors. So how to obtain epoxy potting adhesive products that meet the requirements? Here, the editor recommends Schneider first. Schneider epoxy potting adhesive has been verified in the industry for automotive electronic power capacitor products. You can consult HANAST application engineers first to have a more comprehensive understanding of relevant users and product performance levels.

Home

Home

What factors will affect the defoaming effect of silicone potting compound

What factors will affect the defoaming effect of silicone potting compound  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address