The method and reason of the electronic potting glue to eliminate air bubbles

Nov 28,2022

Nov 28,2022

Hanast

Hanast

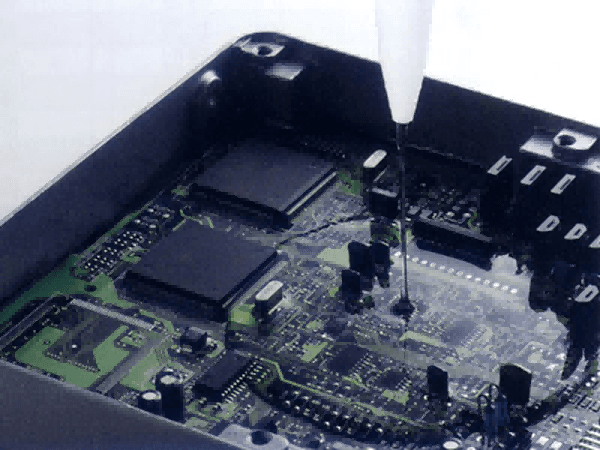

The method and reason of the electronic potting glue to eliminate air bubbles

Bubbles appear during the operation of electronic potting adhesives, which makes it difficult for many users who use electronic potting adhesives. The foam generated during curing will burst as the temperature rises, but there will still be a certain amount of foam that has not been eliminated in time. Yes, these foams will cause defects such as local depressions, shrinkage cavities, and cracks on the surface of the device. This is not in line with the production and processing standards of the process, because it will cause many small pits and unevenness after the colloid is cured, which is a very difficult problem. Question, what is the reason for the bubbles? How to eliminate the bubbles produced by the electronic potting compound? We will give you an answer:

One reason of bubbles: the bubbles brought in during mixing. Air enters during stirring, and the vacuum degree is not enough when injecting the product and vacuuming during the entire curing process, or the time is not enough, and the air is not completely pumped out.

Ways to eliminate bubbles:

1. It is recommended to vacuumize the main agent and curing agent after mixing them together.

2. Preheating the product to be potted will help the escape of air.

3. Curing in a room with low temperature and humidity, so that the air has enough time to escape.

The second reason for the generation of bubbles: the bubbles generated during the curing process. There are several reasons for the generation of bubbles during the curing process: too fast curing speed, high exothermic temperature, large curing shrinkage of the glue, too much solvent and plasticizer in the glue are easy to generate bubbles during the curing process. To solve these problems in the curing process, it is necessary to adjust the overall formula of the glue.

Ways to eliminate bubbles:

1. Potting with professional electronic glue filling machine. The professional electronic glue filling machine has mixing glue filling and vacuum glue filling devices, which is convenient and fast, and is suitable for large-scale production enterprises.

2. Heat the glue solution at 25-30°C before mixing the glue, and then mix the electronic potting glue in proportion. When mixing glue, stir clockwise, the speed is uniform, not fast and slow. The speed should also be uniform when pouring glue, otherwise it is very easy to produce air bubbles.

3. Use low-viscosity electronic potting glue, because low-viscosity silicone is easier to discharge air bubbles.

The third reason for the generation of bubbles: the reaction between moisture and curing agent produces gas; the defoamer is not added enough.

Ways to eliminate bubbles:

There are 4 possibilities for the reaction of moisture and curing agent.

1. The main ingredient has been used many times, and moisture is mixed in every time it is stirred. It is also possible that the lid of the package is not closed tightly. To prove what is the reason, please mix the base and curing agent in a dry cup and put it in an oven (60-80°C) to dry. If bubbles still appear, it means that the main ingredient has deteriorated at this time, please do not use it again.

2. The potted product contains too much moisture, it is recommended to re-test after preheating the product.

3. The surface of the mixture of main agent and curing agent reacts with the moisture in the surrounding air, and it is cured in a dry environment. If the product allows, it can be cured in an oven after heating.

4. The liquid main agent and curing agent mixture may have been in contact with other chemical substances (such as solvents, release agents, varnishes, glues, etc.) before curing, and ensure that these substances are removed before the next test.

Home

Home

What Is The Principle Of Silicone Glue?

What Is The Principle Of Silicone Glue?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address