What are the differences between different potting compound

Jan 29,2024

Jan 29,2024

Hanast

Hanast

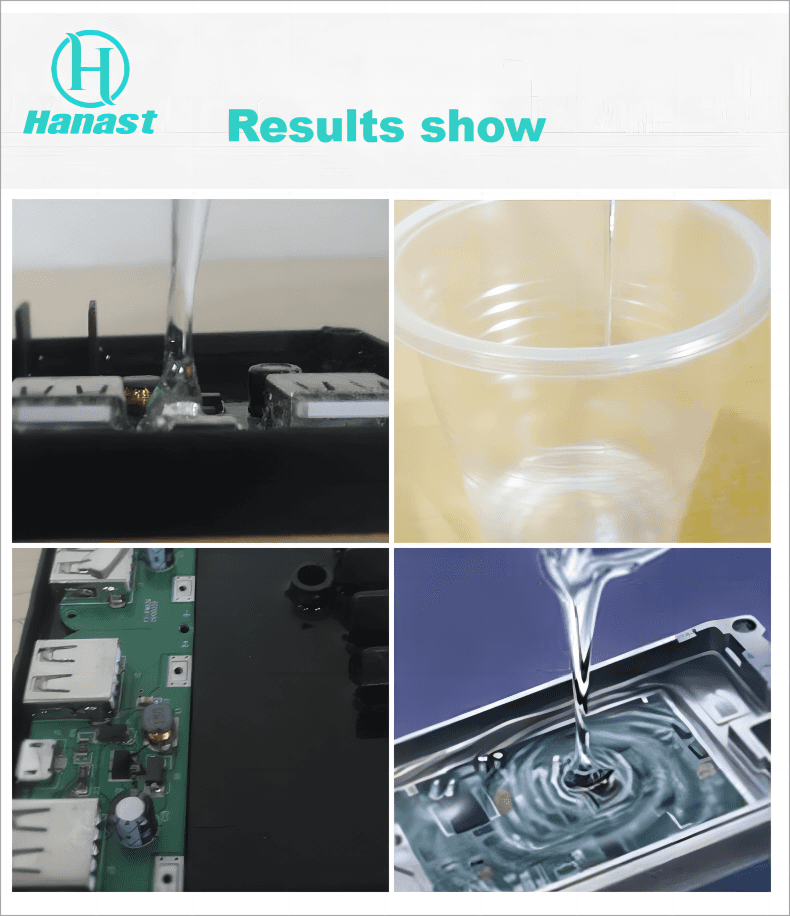

potting compound is a material that is coated or poured onto the surface of electronic components, aiming to provide long-term and effective protection. Different types of sealing adhesives differ in material, performance, and applicable scenarios. The following is a brief introduction to the characteristics and differences of various types of potting compounds:

1. Epoxy resin potting compound :

Features:

▶ Mainly hard, but there are also slightly softer products with modified epoxy resin.

▶ The advantages include good adhesion, good insulation performance, and acid and alkali resistance.

▶ The temperature resistance environment is generally 100 ℃, and transparent epoxy resin has good transparency.

Disadvantages:

▶ The ability to resist cold and hot changes is relatively weak, and it is prone to cracks caused by cold and hot impacts, which affects its moisture-proof performance.

▶ After solidification, the colloid has high hardness and brittleness, making it easy to strain electronic components.

▶ The product is difficult to open after solidification, making it impossible to replace and repair components.

▶ Transparent epoxy resin is prone to yellowing under light or high-temperature conditions.

2. Polyurethane potting glue:

Features:

▶ Has excellent low-temperature resistance and soft materials.

▶ Has good adhesion, with a bonding strength between epoxy resin and organosilicon.

▶ Has good waterproof and moisture-proof performance and insulation.

Disadvantages:

▶ Poor high-temperature resistance and easy foaming require vacuum defoaming.

▶ After curing, the surface of the gel is not smooth, the toughness is poor, the anti-aging, seismic and UV resistance are weak, and it is easy to change color.

Features:

▶ After curing, the material is soft and has two forms: potting glue and gel.

▶ It has stable dielectric insulation and is an effective environmental pollution barrier.

▶ Capable of protecting electrical/electronic devices under various harsh conditions, including high humidity, extreme temperatures, thermal cycling stress, mechanical impact, and vibration.

▶ Has good chemical stability and can resist ozone and UV degradation.

Disadvantages:

▶ Under specific usage conditions, the adhesion may be slightly weak, but it can be solved by adding a primer.

Overall, different types of sealing adhesives are suitable for different application scenarios, and selecting the appropriate sealing adhesive is crucial for improving the operational precision and timeliness of electronic products. In practical applications, it is necessary to choose the most suitable sealing adhesive material based on specific needs and environmental conditions.

3. Organic silicon potting compound:

Features:

▶ After curing, the material is soft and has two forms: potting glue and gel.

▶ It has stable dielectric insulation and is an effective environmental pollution barrier.

▶ Capable of protecting electrical/electronic devices under various harsh conditions, including high humidity, extreme temperatures, thermal cycling stress, mechanical impact, and vibration.

▶ Has good chemical stability and can resist ozone and UV degradation.

Disadvantages:

▶ Under specific usage conditions, the adhesion may be slightly weak, but it can be solved by adding a primer.

Overall, different types of sealing adhesives are suitable for different application scenarios, and selecting the appropriate sealing adhesive is crucial for improving the operational precision and timeliness of electronic products. In practical applications, it is necessary to choose the most suitable sealing adhesive material based on specific needs and environmental conditions.

Home

Home

Common problems with potting adhesive - factors that affect the appearance of potting adhesive?

Common problems with potting adhesive - factors that affect the appearance of potting adhesive?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address