What are the electronic adhesive glue? Electronic adhesive glue classification introduction

May 23,2023

May 23,2023

Hanast

Hanast

Electronic adhesive is a kind of adhesive glue application classification, which is used in industry to connect the same material or different materials with adhesive. Generally speaking, industrial glue has the characteristics of high strength, wide range of applicable temperature, high strength, wide range of viscosity options, low price, and easy production. Due to its convenient use and high efficiency, it replaces many cumbersome fixing methods.

Silicone Adhesive Sealants

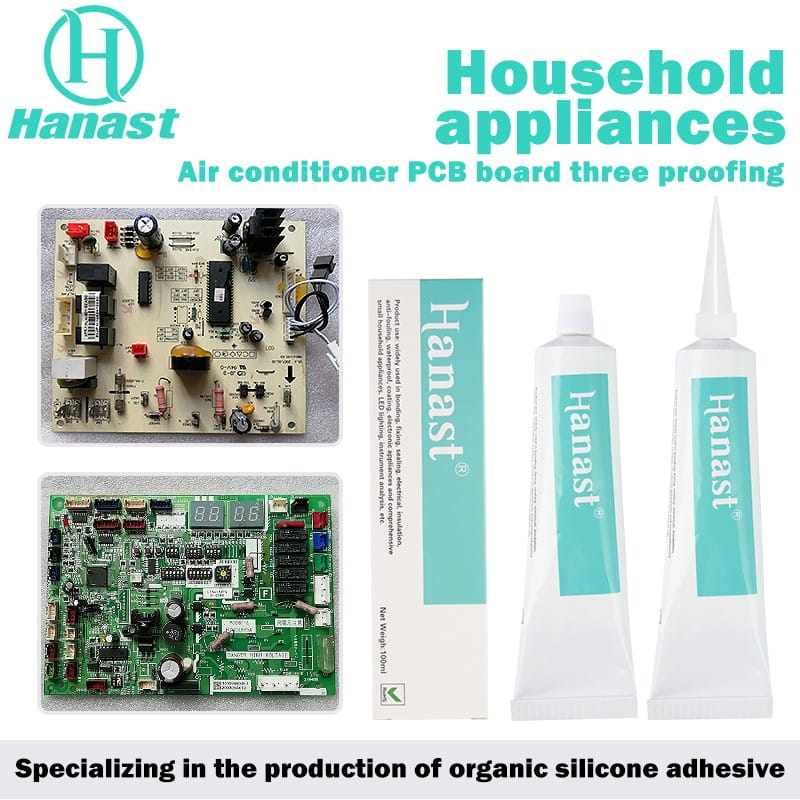

Silicone sealant is a thixotropic micro-collapsing room-temperature-curing one-component silicone adhesive sealant, which is non-corrosive to most metals and has excellent resistance to alternating cold and heat, aging resistance and electrical insulation properties. , Excellent moisture-proof, shock-proof, corona-resistant, anti-leakage, flame-retardant properties. Widely used in lighting, small household appliances, circuit boards, electronic components, switching power supply fields, bonding and sealing, and mechanical bonding and sealing, etc.

Silicone potting compound

Silicone potting adhesive is a low-viscosity flame-retardant two-component silicone adhesive, which can be cured at room temperature or heated, and has the characteristics of faster curing at higher temperatures. This series of products does not produce any by-products in the curing reaction, and can be applied to the surface of PC, PP, ABS, PVC and other materials and metals. It is suitable for heat conduction, insulation, waterproof and flame retardancy of electronic accessories. Its flame retardancy can reach UL94-V0 level and can be used in the environment of -40°C to 200°C. It is widely used in deep potting of power modules and electronic components, especially Suitable for HID power module potting.

Conductive plastic

Conductive silver glue, because of its conductive and electromagnetic shielding functions, is widely used in electronic products, especially in anti-interference circuits for high-frequency signals in mobile phones and wireless communications.

Instant adhesive

One-component adhesive, also known as instant glue or quick-drying glue, can be cured instantly after sticking objects, generally ranging from 10-60 seconds, can have different viscosities, and has good adhesion to metal, plastic, and rubber Sex, the main applications are earphones, data cables, selfie sticks, mobile phone buttons, etc., mobile phone casings, etc.

Epoxy glue

It can be one-component or two-component acrylic resin and epoxy resin. There are two curing methods: heating and room temperature curing. It has the advantages of high shear strength, fast fixing, high temperature and high humidity, impact resistance, and weather resistance. It has high bonding strength to most substrates, and can bond metal, plastic, rubber, glass, etc. The main applications are the bonding and mutual bonding of mobile phone tablet rear shells, notebook shells, and large-area shells.

Hot Melt Structural Adhesive

There are many kinds of hot-melt adhesives, and PUR hot-melt adhesive is one of the best. It has strong adhesive force. It is also called hot-melt structural adhesive. Low temperature, widely used in electronic products, such as mobile phone tablet screen, TP frame, metal and plastic shell bonding, and bonding of most product screens.

Polyurethane adhesive

One-component or two-component adhesives have good bonding properties for thermoplastics and thermosetting plastics with slight surface treatment. There are three curing methods: catalytic curing, thermal curing, and solvent evaporation curing. Generally, the curing is slow. Has good flexibility and durability.

Anaerobic adhesive

One-part adhesive/sealant that cures only in the absence of air. Used for thread locking, cylinder holding, pipe thread sealing, flat sealing, etc.

UV shadowless glue

UV curing adhesive is one-component, solvent-free, also called shadowless glue or ultraviolet curing glue. It takes a long time to operate and can be cured in a few seconds under UV light. This advantage makes it widely used. One side should be transparent. Applications include solder joint reinforcement, cable reinforcement, fixing, and coating.

Conclusion:

As a kind of polymer material, adhesive has a long history and played an important role in human industrial civilization. With the innovation of raw materials and the update of production technology, the use of adhesives is not limited to traditional industries, but also develops in the direction of refinement and specialization, and constantly explores and expands different application fields.

Home

Home

The Role of Electronic Adhesives in Modern Manufacturing

The Role of Electronic Adhesives in Modern Manufacturing  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address