What is silicon gel

Jan 29,2024

Jan 29,2024

Hanast

Hanast

Silicone gel is a kind of extra soft silicone rubber with hardness, environmental protection, non-toxic and tasteless. Its application field is more and more extensive. Since it is as soft as jelly after curing, it is also called jelly glue. The surface is naturally sticky after curing. The natural viscosity can enable the silicon gel to enhance the physical adhesion to most substrates without the need for primer. This kind of natural viscosity has regenerative characteristics. Now HANAST will introduce the relevant knowledge of two-component addition molding silicone gel.

1、 Characteristics:

1. Stable physical and chemical properties, with a wide temperature resistance of -60~230 ℃;

2. Low viscosity, easy to use, no solid fillers, fully transparent, and easy to observe sealing components;

3. Capable of repeated operation, repairability, high flexibility, and extremely low shrinkage rate;

4. Good dust-proof, moisture-proof, shockproof, insulation, and other performance;

5. After solidification, the surface becomes naturally sticky, enhancing the physical adhesion of most substrates without the need for a primer;

6. It can be cured at room temperature or by heating, with the characteristic of faster curing at higher temperatures, and the curing time can be freely controlled;

7. During the curing process, no by-products are generated and can be applied to materials such as PC, PP, ABS, PVC, and the surface of metals;

2、 Typical applications:

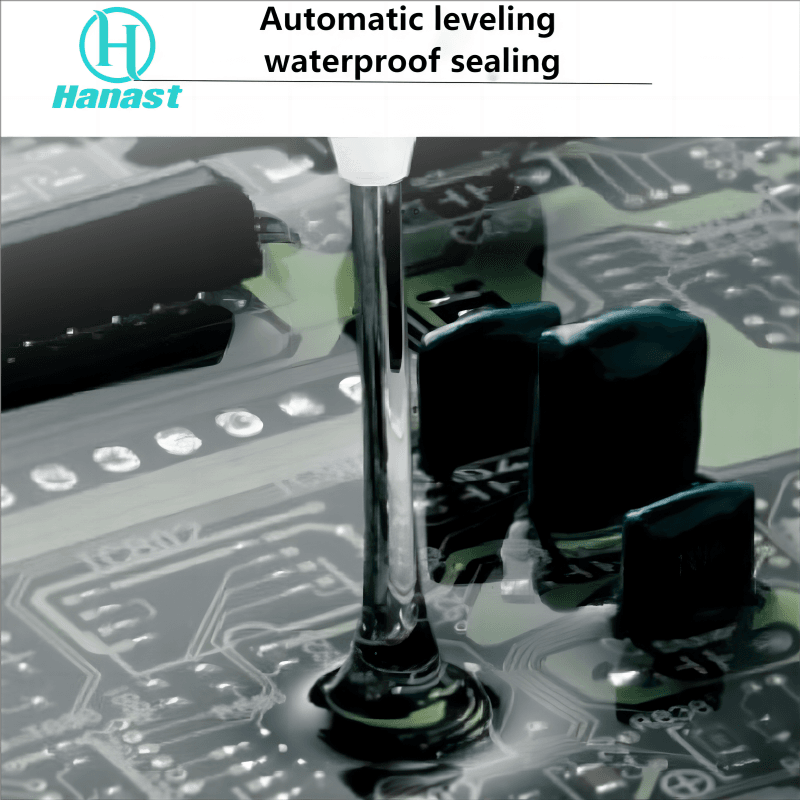

1. Applied for sealing protection of precision electronic components, bathrooms, backlights, solar energy, connectors, etc;

2. Sealing protection of power modules and other electronic components;

Features of silicon gel | Typical application of silicon gel | Precautions for use of silicon gel. Schneider

3、 Precautions for use:

1. Before mixing, first thoroughly stir component A and component B in their respective containers.

2. At room temperature in winter, the curing time will be extended, and heating curing can be chosen;

3. The mixed adhesive should be used up at once to avoid waste;

4. Defoaming can be carried out as needed during use. Mix the mixture of A and B evenly and put it into a vacuum container. After defoaming at a vacuum degree of -0.095MPa to -0.1MPa, it can be poured and used.

5. Avoid contact with organic tin compounds, silicone rubber containing organotin, sulfur, sulfides, sulfur-containing rubber materials, amine compounds, and amine-containing materials to prevent poisoning;

Home

Home

What is organosilicon silicone gel?

What is organosilicon silicone gel?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address