506 Series

One- Component RTV Bond Sealing Silicone Rubber

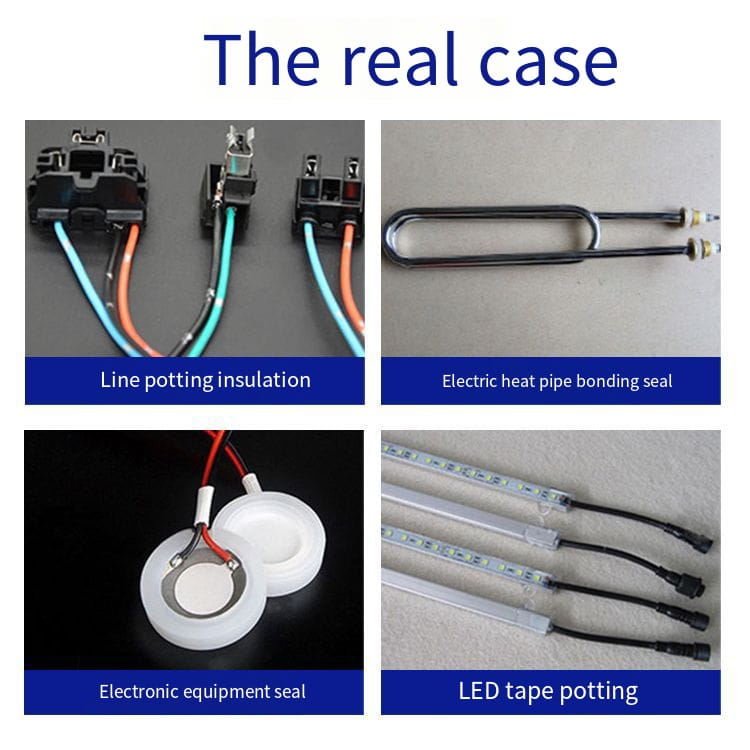

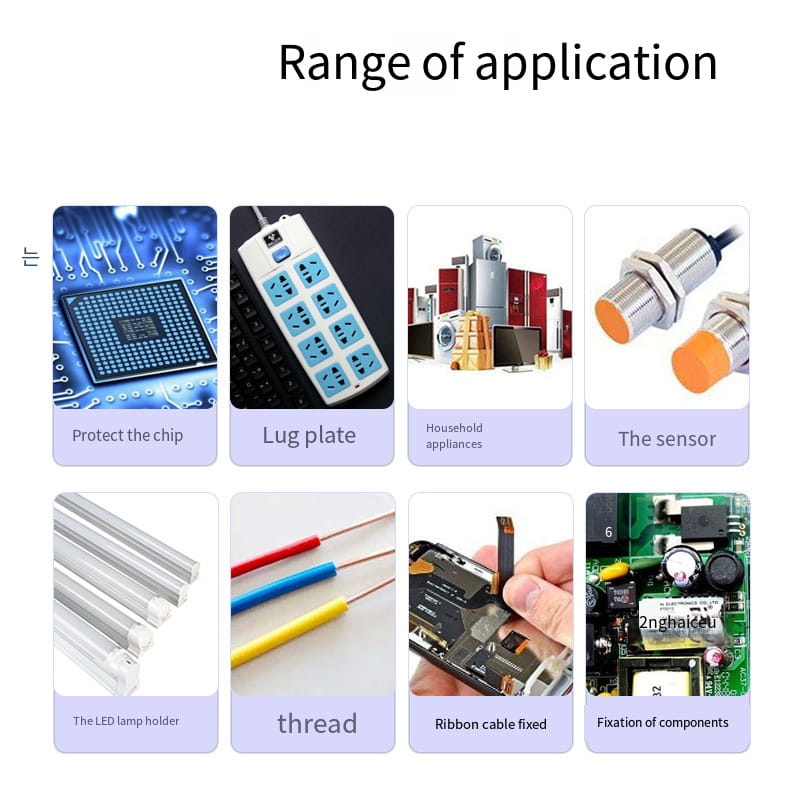

❆ Product use:

It is widely used in electronic components, lighting components, instruments, motors, household appliances and other equipment. The function is sealing, moisture -proof, shock absorption and insulation materials.

❆ Product characteristics:

1. Has excellent adhesion, fixing, sealing, electrical, insulation, moisture -proof, shockproof, sealing, high temperature resistance, aging resistance and other properties;

2. The hardening silicone RTV silicone rubber can exert the electrical characteristics of the original silicone, and in the temperature of -50 ℃ ~ 200 ℃, it has a good extension rate (can also maintain its original rubber elasticity) , And have weather resistance, heat resistance, cold resistance;

3. Excellent adhesion, can have good adhesion with metal, glass, tiles, plastics (except PE, PP) and its alloy;

4. Comply with EU ROHS instructions.

❆ How to use:

According to the amount of dosage, cut the head of the nozzle to the head, and put it with a special syringe (air gun or pistol) to use it to use it. The room temperature is curing.

❆ Precautions:

1. If you need to obtain the best bonding performance, the surface of the adhesive substrate should be clean, without rust, dust and oil pollution. It can be expressed in the bonding substrate such as water -free ethanol or propane.

2. You can manually or use the dot -glue device to apply it to the substrate that needs to be bonded. The moisture in the exposure of the rubber in the air is solidified from the manifestation to the inside. Their drying and curing speed are related to the environmental temperature and humidity used. The thickness of the glue layer: the thickness of the rubber layer ≤1mm, at the temperature of 25 ± 2 ° C, the relative humidity 50 ± 5 5 Under the conditions of %, it can be put into use for 24 hours. The thicker the glue, the longer the curing time.

3. After the operation is completed, the unused glue should be tightened immediately, the seal is stored, and when it is appropriate again, if there is a little skin at the seal, it can be removed without affecting the normal use. During the storage process, a small amount of solidification or oil analysis may also occur at the mouth of the tube. After removing it, it can be used normally without affecting product performance.

4. Avoid contact with the eyes and skin. If you accidentally contact your eyes during operation, immediately rinse medical rescue with a lot of water. Keeping ventilation in the place of use is limited to industrial journey.

❆ Product packaging

100ml/branch, 310ml/support, 2600ml/support

❆ Storage

1. Store below 30 ° C in a cool and dry place with a storage period of 6 months.

2. Products that exceed the storage period should be confirmed that there are abnormalities before they can be used.

3. Such products are non -dangerous goods and can be transported according to general chemicals.

It must be kept secret and be careful of leakage during transportation.

❆ Technical parameters

|

Model

|

HN-506W-1

|

HN-506B-2

|

HN-506W-1

|

HN-506W-2

|

HN-506G-1

|

|

Type

|

Ketoxime RTV

|

Alcohol

RTV

|

Ketoxime RTV

|

Alcohol RTV

|

Ketoxime RTV

|

|

Exterior

|

white, flowing

|

black, flowing

|

white, creamy

|

white, semi-fluid

|

grey, semi-fluid

|

|

Viscosity (mPa.S)

|

15000~17000

|

18000~25000

|

-------

|

----------

|

35000~45000

|

|

Specific gravity (25℃)

|

1.0~1.04

|

1.0~1.1

|

1.15~1.2

|

1.25~1.35

|

1.8~2.2

|

|

Surface dry time (min25℃)

|

10~30

|

5~15

|

10~30

|

5~15

|

10~30

|

|

Shore hardness (JISA)

|

25~35

|

20~30

|

40~50

|

40~50

|

50~60

|

|

Elongation at break (%)

|

150~230

|

300~400

|

200~280

|

200~280

|

150~250

|

|

Tensile strength (Kgf/cm2)

|

15~25

|

15~30

|

15~30

|

15~30

|

20~30

|

|

Volume resistivity (Ω.cm)

|

≥3×1014

|

≥3×1014

|

≥3×1014

|

≥3×1014

|

≥3×1014

|

|

Breakdown voltage (kv/mm)

|

18~25

|

18~25

|

18~25

|

18~25

|

18~25

|

|

Positive dielectric loss angle (1MHZ)

|

≤4×10-3

|

≤4×10-3

|

≤4×10-3

|

≤4×10-3

|

≤4×10-3

|

|

High and low temperature resistance (℃)

|

-50℃~250℃

|

-50℃~200℃

|

-50℃~250℃

|

-50℃~200℃

|

-50℃~250℃

|

COMPANY PROFILE

Shenzhen Hanast Technology Co, Ltd. was established on 2019. The factory is located in Sanming City, Fujian Province,

covering an area of 20,000 square meters.

Hanast is a silicone raw material company integrating R&D, production and sales, mainly engaged in conventional silicone

rubber,special silicone rubber, RTV adhesive sealant, two-component electronic potting adhesive, thermally conductive

silicone, thermally conductive silicone grease, lubricating silicone grease, damping silicone grease, platinum vulcanizing

agent and other silicone raw materials.

The products comply with ROHS standard, obtain SGS, Food Grade Certification, and the enterprise passed ISO9001. 2015

certification. Our products have obtained many national invention patents and utility model patents, and are widely used in

silicone kitchenware, high temperature wire and cable, industrial silicone rollers, medical industry, baby products, sporting

goods, adult products, new energy vehicles and other fields.

CERTIFICATIONS

CUSTOMERS

Home

Home

Related Suggestion

Related Suggestion

Nov 17,2023

Nov 17,2023

Tel

Tel

Email

Email

Address

Address