Classification And Use Of Electronic Glue

May 23,2023

May 23,2023

Hanast

Hanast

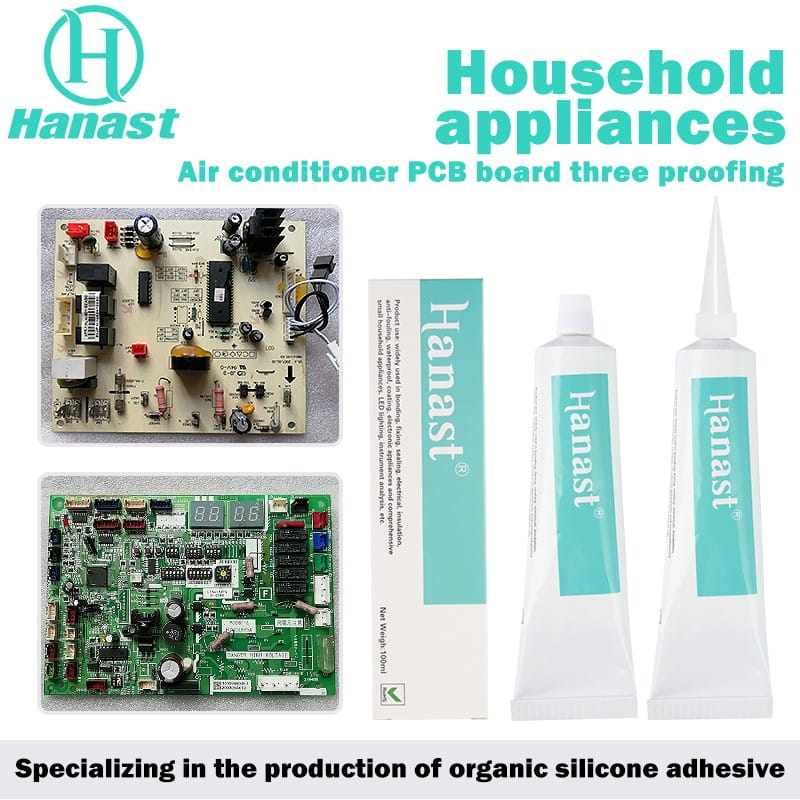

The main representatives of electronic glue are 【silicone sealant】 and【silicone potting glue】.

Room temperature vulcanized silicone rubber or silicone gel is used for the potting of electronic and electrical components, which can prevent moisture, dust, corrosion, and shock, and improve the performance and stability parameters, and it is liquid before vulcanization, which is convenient Prime and easy to use. When using silicone gel for potting, no low molecular weight is released, no stress shrinkage, deep vulcanization without any corrosion, it becomes a transparent elastic body after vulcanization, the components encapsulated in the glue layer are clearly visible, and can be pierced with needles Go inside to measure component parameters one by one, which is convenient for inspection and repair. Room temperature vulcanized foamed silicone rubber is used for memory core boards in electronic computers, and it fully meets the requirements after many tests such as vibration, impact, and alternating heat and cold. The flame-resistant potting compound prepared on the basis of addition-type room temperature vulcanized silicone rubber is very effective for molding high-voltage caps for TV sets and sheaths for high-voltage cables. When it is not necessary to carry out airtight packaging or it is inconvenient to carry out impregnation and potting protection, one-component room temperature vulcanized silicone rubber can be used as the surface coating protection material. Generally, the surface protection coating of electronic components is made of room temperature vulcanized silicone rubber, and the inner coating is carried out with addition type silicone glue.

Silicone sealant

Silicone sealant is a one-component, non-dripping paste, dealcoholized RTV silicone rubber. It is through the condensation reaction of moisture in the air to release low molecules to cause cross-linking and curing, and vulcanize into high-performance elastomers. It has excellent resistance to alternating cold and heat, aging resistance and electrical insulation. And it has excellent insulation, moisture-proof, shock-proof, corona resistance, leakage resistance and chemical medium resistance, and can be used continuously at -60~~200°C and maintains performance. It can seal and bond electronic components without polluting the surrounding environment, and fully complies with the requirements of the EU ROHS directive.

use

This product is suitable for various structural bonding and sealing in industrial production, such as: structural bonding of steel plates in automobile compartments; insulation bonding and sealing of high-voltage parts such as TVs, power supplies, CRT picture tubes, and DY deflection coils; sensitive PCBs Fixing and bonding of components, capacitors, triodes, etc.; bonding and sealing of refrigerators, microwave ovens, induction cookers, circuit boards, electronic components, and solar energy; moisture-proof and waterproof packaging of delicate electronic accessories; sealing of automotive headlight gaskets; internal paste of power plant pipes Bonding and sealing reinforcement of wear-resistant ceramic sheets and window frame mounting glass; elastic bonding to most metal and non-metallic materials, especially suitable for elastic bonding in environments with special temperature requirements; electric power, electronics, electrical appliances, medical Machinery, sensors, mechanical equipment, refrigeration equipment, shipbuilding industry, automobile industry, chemical light industry, insulation bonding reinforcement sealing protection of wires and cables, etc.

Silicone potting compound

Silicone potting compound is a one-component, low viscosity, dealcoholized room temperature curing silicone high temperature bonding potting compound. It is through the condensation reaction of moisture in the air to release low molecules to cause cross-linking and curing, and vulcanize into high-performance elastomers. It has excellent resistance to cold and heat changes, stress changes, etc., high and low temperature resistance, long-term elasticity and stability at high temperatures, UV resistance, and aging resistance. And has excellent insulation, moisture-proof, shock resistance, corona resistance, leakage resistance and chemical medium resistance. It can seal and bond electronic components without polluting the surrounding environment, and fully complies with the requirements of the EU ROHS directive.

use

This product is suitable for various structural adhesive potting in industrial production, such as: power supply, LED module potting; photoelectric display, electronic components, electrical modules, semiconductor equipment, circuit board waterproof and moisture-proof; light bulb outer surface, etc. Coating; thin-layer potting insulation protection; moisture-proof, waterproof packaging, insulation and coating protection of various circuit boards for delicate electronic accessories; waterproof coating for electrical and communication equipment; waterproof packaging for LED Display modules and pixels; metal Elastic bonding with non-metallic materials; potting of various optical instruments, chemical equipment, sight glasses, electrical equipment, small household appliances, etc.; waterproof and shockproof bonding of underwater instruments; elastic bonding of various electronic and electrical sensors seal up

Home

Home

What are the application industries of liquid silicone?

What are the application industries of liquid silicone?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address