What are the application industries of liquid silicone?

Jun 02,2023

Jun 02,2023

Hanast

Hanast

In addition to traditional fields such as construction, electric power, machining, textiles, leather, daily necessities, personal care products, and medicine, organic silicon is widely used in solar energy, wind power, high-speed rail, automobiles, electronic information technology, medical and health care, and high-end manufacturing and energy saving in recent years. Applications in industries such as environmental protection are also expanding.

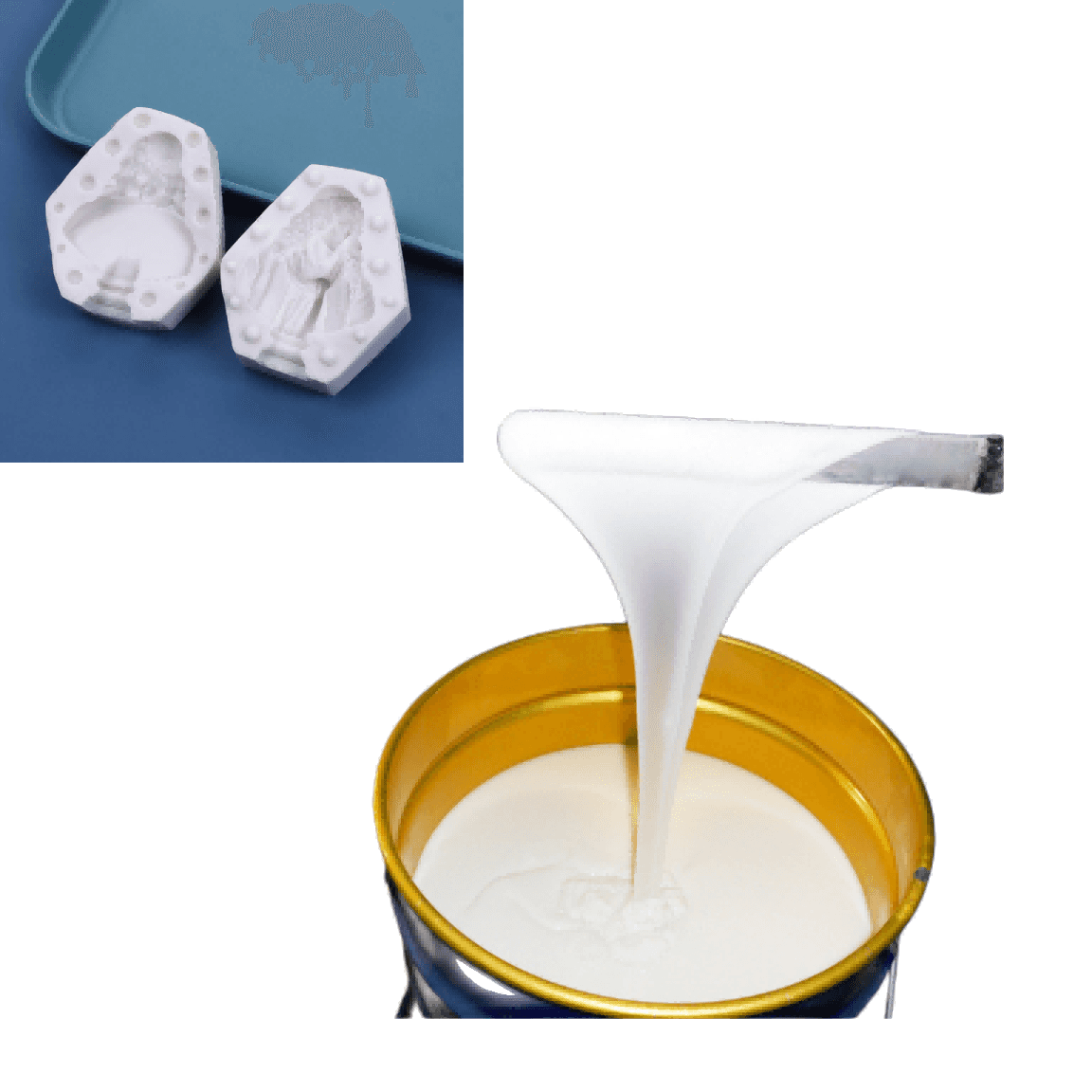

The special material properties of liquid silicon only cure through crosslinking. Interestingly, LSR is always applied where conventional and thermoplastic elastomers (TPE) reach their limits. LSR also has very good resilience properties, high heat resistance (partly over 180°C), low temperature flexibility (minimum about -50°C), high electrical insulation properties, tensile and breaking strength, and physiologically stable are harmless.

From the product classification, application characteristics and precautions of silica gel, silica gel raw materials, and liquid silica gel raw materials, there will be differences. After continuous development and research, silica gel has been widely used in various fields of modern industry, such as , medical care, infant care, smart wear, automotive and aerospace and other fields. Familiarity with the application technology and main application of silica gel raw materials and liquid silica gel raw materials will help us discover, research and explore deeper and wider.

With the decrease of global coal and oil resources, the trend of organosilicon products replacing traditional petrochemicals is becoming more and more obvious.

Used as a sealant for road joints; sealing of high-rise building panels, curtain walls and interior wall joints; filling of gaps around kitchen tiles and sealing around bathtubs, buckets, and urinals, etc.

Home

Home

The main application of condensation liquid silicone rubber

The main application of condensation liquid silicone rubber  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address