Classification of liquid silicone applications

Sep 18,2023

Sep 18,2023

Hanast

Hanast

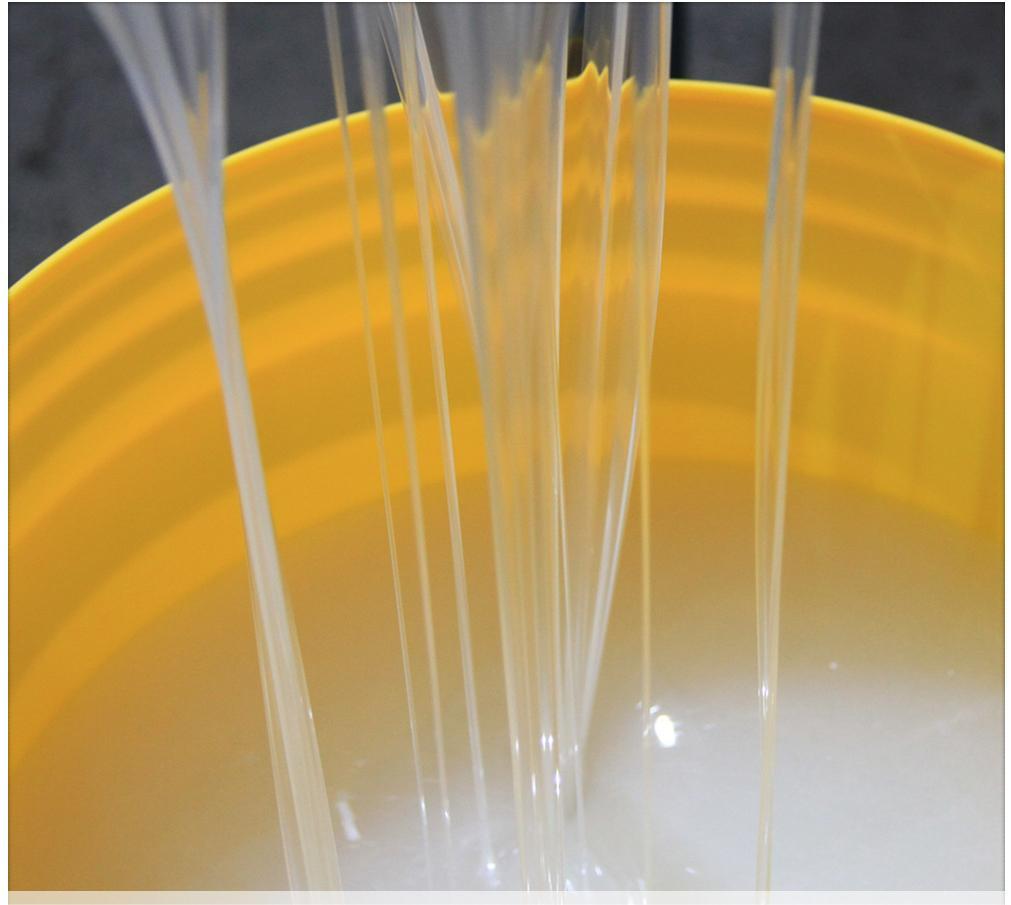

Liquid silicone is divided into additive liquid silicone and condensed liquid silicone, both of which are AB dual component silicone and liquid silicone rubber; Component A is a flowable liquid silicone, while Component B is a curing agent. After mixing the two, it can be quickly formed. Among them, condensed silicone is non food grade, that is, industrial grade silicone, and added silicone is food grade silicone.

Liquid silicone can be divided into the following categories based on its performance and usage:

1. Mold silicone

Mold liquid silicone is a new type of molding material, and silicone molds made from mold silicone have significant advantages in production efficiency and production cost compared to steel molds. Nowadays, mold silicone has been widely used in the toy and gift industry, medical, electronic, mechanical fields, character reproduction, home building decoration and decoration industry, unsaturated resin handicraft industry, simulated animal and plant sculpture, Buddha carving handicraft and other industries for mold production.

2. Human silicone

Human silicone: It is a liquid silicone with low solidification hardness, which is environmentally friendly, non-toxic, and has no adverse effects on human objects. Therefore, it can be implanted into the human body and is usually used for making prosthetics. It can also be used to simulate characters, etc.

3. Transfer printing silicone

Transfer printing liquid silicone is used to make transfer printing heads, mainly used for printing plastic toys, electroplating products, electronic toys, trademarks, and irregular patterns. Transfer printing adhesive head is to use the pattern on the steel plate as a carrier through the adhesive head, and then transfer the pattern on the steel plate onto the toy product. The hardness of transfer printing liquid silicone can be controlled by adding silicone oil.

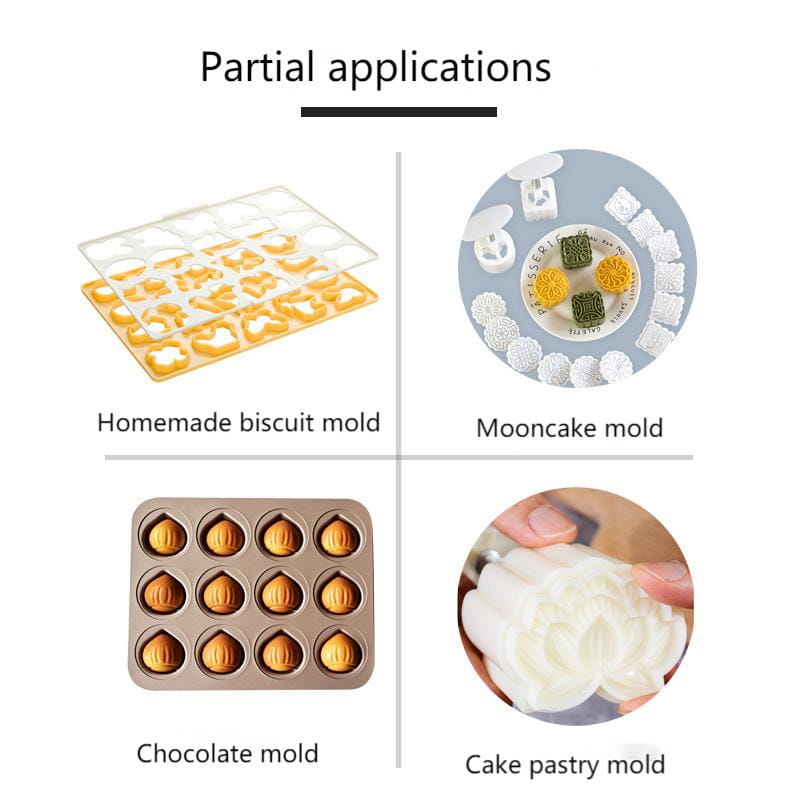

4. Food grade silicone

Silicone for food use is an inorganic polymer colloid material formed by the condensation of silicic acid. The main component is SiO2 · nH2O, with a content of over 98%. It is non-toxic, odorless, and has stable chemical properties. Under normal conditions, it does not react with any acid, alkali, or salt except for caustic soda and hydrofluoric acid. Due to its colloidal structure, it has many micropores and a large specific surface area. The pore size of edible silicone is about 8-10nm, with a specific surface area of 300-500m2/g. The surface is hydrophilic and has strong water absorption ability. Under high humidity conditions, its water absorption can reach over 80% -100% of its own weight. So food grade silicone can be used as an external desiccant for food and medicine. Due to the fact that edible silicone is refined and sterilized, it can be mixed with food and drugs in the required amount to directly ensure the dryness of the food and consumed together with the food, without any toxic or side effects on the human body.

5. Electronic potting silicone

Electronic potting liquid silicone is mainly used for sealing electronic products. By using electronic sealing liquid silicone, electronic products can be sealed, waterproof, dustproof, thermally conductive, shockproof, and insulated. In addition, one type of encapsulation adhesive is used for LEDs, which has high transparency and refractive index characteristics.

6. Hand board silicone

Hand board liquid silicone, also known as the first version of silicone, is usually used to make hand board models. Compared to hand board oil mud, hand board liquid silicone has the characteristics of wear resistance and strong resilience after curing.

Home

Home

How to Discharge the Bubbles Produced by Mixing Liquid Silicone

How to Discharge the Bubbles Produced by Mixing Liquid Silicone  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address