How to solve the high shrinkage rate of silicone mold making

Sep 18,2023

Sep 18,2023

Hanast

Hanast

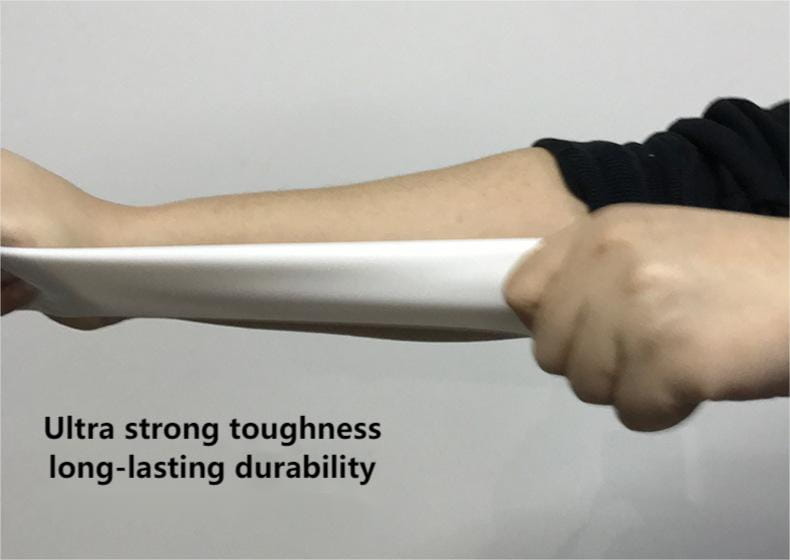

Whether it is industrial grade mold silicone or food grade mold silicone, they are both two component liquid silicone, and there will be some shrinkage during the mold making process; Industrial grade mold silicone generally refers to condensed silicone, which produces low molecules during crosslinking reaction and has a relatively high shrinkage rate. High quality condensed mold silicone has a shrinkage rate of ≤ 0.2%; Food grade mold silicone How to solve the high shrinkage rate of silicone mold makinggenerally refers to additive silicone, which does not produce low molecules during crosslinking reaction and has a relatively low shrinkage rate. High quality additive mold silicone has a shrinkage rate of ≤ 0.1%.

But what if there is a significant shrinkage rate when making molds with silicone?

As the editor of a liquid mold silicone factory, I have summarized some experiences and shared them with everyone here.

The reason for the high shrinkage rate of mold silicone:

1. Any material has a certain degree of shrinkage, and silicone rubber has a relatively small shrinkage rate compared to many materials;

2. The storage method of the mold is incorrect;

3. The larger the product size, the more obvious the shrinkage;

4. Do not add fiberglass cloth for large products;

5. Moulding masters often do not mix the adhesive according to the manufacturer's AB component mixing ratio, but increase the proportion of curing agent based on their own experience;

6. The mold is not fully cured, and the hardness of the silicone is not stable. Urgent demolding or early production results in the silicone mold being prone to deformation and shrinkage.

Solution to silicone shrinkage in molds:

1. It is necessary to scale up the original mold type by 2-3% to ensure that the product size produced is within the range;

2. When the mold is not in use, pour gypsum water to store it. When it is produced again, remove the gypsum and start production, so that the silicone mold will not shrink when stored;

3. Adjust the adhesive according to the mixing ratio of AB components from the manufacturer;

4. When making large product molds, fiberglass cloth should be added, preferably with 2-3 layers of fiberglass cloth or gauze, to ensure that the mold does not deform or become larger;

5. The mold must be completely cured before demolding, and can only be put into production after being left for 24 hours;a

Home

Home

Classification of liquid silicone applications

Classification of liquid silicone applications  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address