How to use thermal conductive silicone grease? How to select thermal conductive silicone grease

Oct 06,2023

Oct 06,2023

Hanast

Hanast

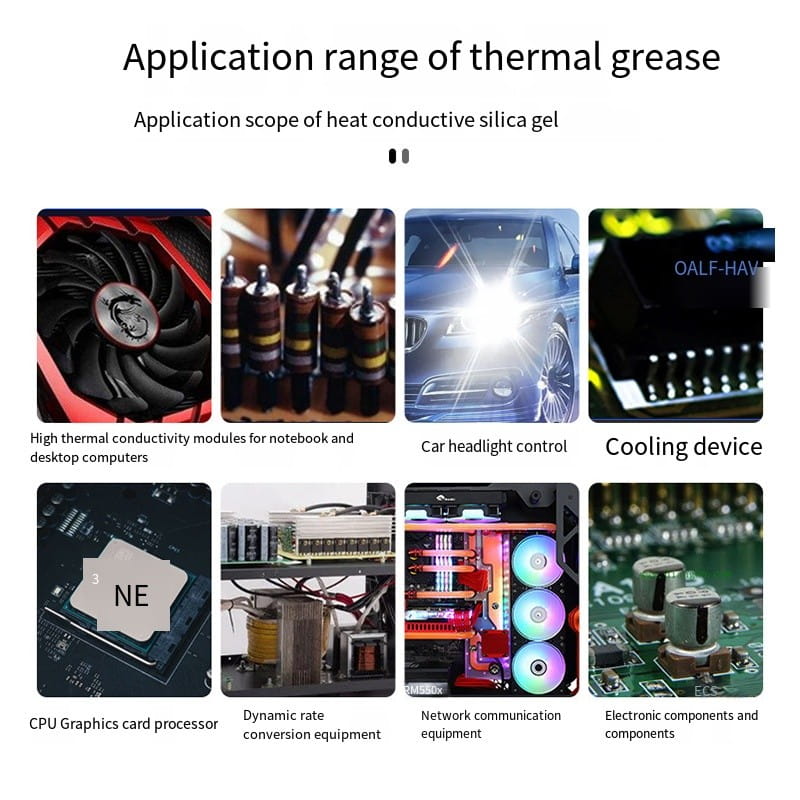

Thermal conductive silicone grease, commonly known as heat dissipation paste, is a high thermal conductive insulating organic silicon material that can maintain its paste state when used for a long time at temperatures ranging from -30 ℃ to 180 ℃. Thermal conductive silicone grease has excellent electrical insulation and thermal conductivity, as well as low degree of freedom and resistance to high and low temperatures. It is widely used in various electronic products and electrical equipment as the contact surface between the heating element (power tube, controllable silicon, electric heating stack, etc.) and the heat dissipation facilities (heat sink, heat strip, shell, etc.), serving as a heat transfer medium.

When selecting thermal conductive silicone grease, the applicability of thermal conductive silicone grease can be simply evaluated through the following aspects.

1、 Thermal conductivity and thermal impedance

The thermal conductivity is one of the most important performance parameters of thermal conductive silicone grease. The thermal conductivity refers to the amount of heat transferred through an area of 1 square meter within 1 second by a material with a thickness of 1 meter and a temperature difference of 1 Kelvin (K) on both sides of the surface under stable heat transfer conditions λ Represented in watts per meter Kelvin (W/m · K). The thermal conductivity is related to factors such as material structure, density, humidity, temperature, pressure, etc.

Thermal impedance refers to the ratio of the temperature difference between the two ends of an object and the power of the heat source when heat is transmitted, expressed in Kelvin per watt (K/W) or Celsius per watt (℃/W). When heat flows through two solid interfaces in contact, the interface itself exhibits a significant thermal resistance to the heat flow, known as contact thermal resistance.

For the application of thermal conductive silicone grease, the measures to reduce contact thermal resistance are:

1) Improve the thermal conductivity of thermal conductive silicone grease;

2) Reduce the coating thickness of thermal conductive silicone grease, i.e. the thickness of the adhesive layer;

3) Increase the pressure between the interfaces to make the two contact surfaces closer together.

It should be noted that silicone grease with higher thermal conductivity, although theoretically its heat transfer effect is better, does not necessarily mean that the thermal impedance is smaller. In practical applications, more attention should be paid to how to reduce the thermal impedance. Therefore, the amount of thermal conductive silicone grease used is not as much as possible, and the coating thickness should be as thin as possible while ensuring that the amount can fill the gap. Excessive coating thickness can lead to an increase in heat transfer paths and interface thermal resistance, which can have an adverse impact on heat transfer efficiency. In addition, excessive use of silicone grease can cause silicone grease to precipitate during the movement and use of electronic devices, and can also easily lead to adverse phenomena such as oil leakage and fogging, affecting the effectiveness of use.

2、 Fineness

Fineness refers to the degree to which powdered materials such as fillers are finely dispersed in the binder, expressed in micrometers (um). Fineness can characterize the fineness of silicone grease. The smaller the fineness, the smaller the particle size of the thermal conductive filler used for silicone grease, the thinner the thickness that silicone grease can be coated, and the smaller the thermal resistance of the interface. The appearance of silicone grease with high fineness is rough, the coating thickness is large, the coating is loose, porous, and not dense, and the thermal resistance of the interface is also large, which can affect the heat transfer effect.

3、 Construction performance

Thermal conductive silicone grease is mainly composed of matrix silicone oil and thermal conductive filler, and its construction performance is closely related to the filling amount, particle size, morphology, dispersion state, and compatibility with silicone oil of the thermal conductive filler. Usually, it is hoped to maximize the filling of fillers to achieve higher thermal conductivity; Use smaller particle size fillers to achieve thinner coating thickness and contact thermal resistance.

This makes the filling process complex and competitive: the thermal conductivity, coating thickness, and viscosity of silicone grease increase with the increase of filling amount. The viscosity affects the workability of silicone grease and the contact thermal resistance between silicone grease and the interface. The particle size of the filler limits the filling amount and the minimum coating thickness that silicone grease can achieve. These factors will have an impact on the construction performance of thermal conductive silicone grease. In practical applications, different rheological properties of silicone grease need to be selected based on different construction methods. Thermal conductive silicone grease can generally be divided into flowing silicone grease, thixotropic silicone grease, and semi flowing silicone grease based on their rheological properties

The construction methods of thermal conductive silicone grease can be divided into pen coating, spot coating, brush coating, glue dispensing, and screen printing, and suitable products need to be selected for different construction methods. Generally speaking, manual construction such as spot coating and brushing requires the use of low viscosity flowing silicone grease. Automatic dispensing tends to use silicone grease with good thixotropy, while screen printing requires silicone grease to have good coating performance.

In summary, when selecting thermal conductive silicone grease products, it is necessary to consider the thermal conductivity, rheological properties, and construction performance of thermal conductive silicone grease based on the needs of component thermal design and construction methods. On this basis, it is recommended to choose silicone grease with small fineness and thin adhesive layer thickness. In addition, attention should also be paid to the long-term stability and reliability of silicone grease in the application process.

Home

Home

Introduction to the Advantages and Application Fields of Organic silicone compound

Introduction to the Advantages and Application Fields of Organic silicone compound  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address