Introduction to the Advantages and Application Fields of Organic silicone compound

Oct 06,2023

Oct 06,2023

Hanast

Hanast

Silicone potting compound not only has better modification ability and electrical insulation ability than epoxy resin, but also has excellent resistance to cold and hot impacts. It can withstand cold and hot impacts from -60 ℃ to 200 ℃ without cracking and maintaining elasticity, improving the moisture-proof performance of electronic components. Because it is cured into an elastomer, potting in electronic components can also have good impact resistance, It also has excellent resistance to outdoor ultraviolet radiation and atmospheric aging. Electronic components that can be widely used in various harsh environments. For example, outdoor transformers, power modules, ignition coils with high temperature resistance requirements, and electronic equipment in coastal areas.

Characteristics of Silicone potting compound

1. It has an excellent temperature resistance range and can be used for a long time at -50 ℃ to 200 ℃.

2. During curing, it does not absorb or release heat, and does not shrink after curing, resulting in good adhesion to the material.

3. It has excellent electrical and chemical stability, water resistance, ozone resistance, and weather resistance.

4. After encapsulating electronic components, it can play a role in moisture-proof, dustproof, anti-corrosion, and shockproof, improving performance and stabilizing parameters.

5. Excellent thermal conductivity, with a thermal conductivity coefficient more than 4 times that of ordinary rubber.

6. Easy to use, simple coating or potting process, and can cure at room temperature.

Advantages of Silicone potting compound

1. Strong aging resistance, good weather resistance and excellent impact resistance.

2. Has excellent resistance to cold and hot changes, can be used within a wide working temperature range, can maintain elasticity within the temperature range of -50 ℃ to 200 ℃, and does not crack.

3. It has excellent electrical performance and insulation ability, effectively improving the insulation between internal components and circuits after encapsulation, and improving the stability of electronic components.

4. It has no corrosiveness to electronic components and does not produce any by-products during the curing reaction.

5. With excellent repair ability, it can quickly and conveniently remove, repair, and replace sealed components.

6. It has excellent thermal conductivity and flame retardancy, effectively improving the heat dissipation capacity and safety factor of electronic components.

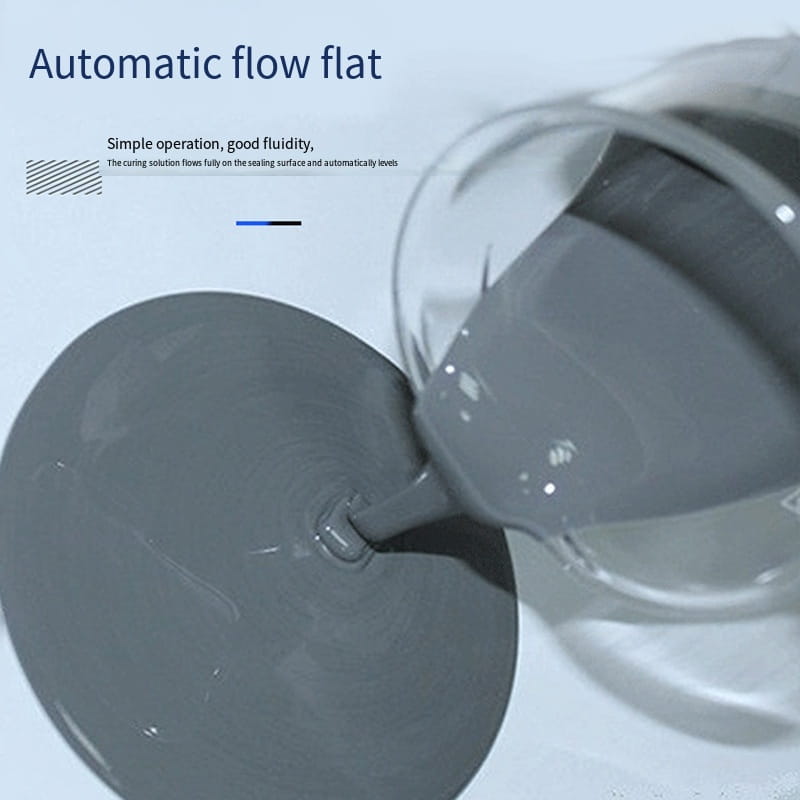

7. Low viscosity, good flowability, able to penetrate into small voids and under components.

8. It can be cured at room temperature or at elevated temperature, with good self foaming performance and more convenient use.

9. Low curing shrinkage rate, excellent waterproof performance and seismic resistance

Scope of application: Suitable for encapsulating various electronic components that work in harsh environments.

Industry Application of Silicone potting compound

1、 Applications in the field of electricity silicone potting compound for electronics

Due to its excellent insulation performance, the thermal expansion coefficient is low; Waterproof performance can effectively prevent the entry of condensed water into the solidified gel; Corrosion resistance ensures long-term operation in acid and salt environments; Its excellent aging resistance allows it to have a service life of up to 50 years, making it widely used for insulation, moisture-proof sealing, environmental protection and anti-corrosion, as well as packaging and bonding of cable accessories.

2、 Applications in the electronics and radio industries

Room temperature curing silicone sealant is widely used in the field of encapsulation, pouring, bonding, impregnation, and coating. It can be used to encapsulate integrated circuits, micro film components, thick film components, electronic assemblies, or complete machines. The components inside the adhesive layer are clearly visible and can accurately measure component parameters.

3、 Application electronic potting silicone

Sealing adhesive is used on various control modules to provide overall and general sealing for components, in order to meet the basic requirements of moisture, dirt, and corrosion prevention. The use of silicone sealant can achieve the function of reducing stress and withstanding high and low temperature impacts. For high-power control modules, thermal conductive potting adhesive is used to achieve heat dissipation.

4、 Application in the power supply industry

Due to the unique properties of organic silicon materials, such as moisture resistance, hydrophobicity, electrical insulation, high and low temperature resistance, chemical stability, and other excellent properties, some varieties also have outstanding advantages such as radiation resistance, oil resistance, and solvent resistance, as well as stable physical and chemical properties. In recent years, it has been widely developed and applied in the power industry, and is a typical technology intensive and high value-added product.

Home

Home

Summary of common problems and solutions during the use of potting compound

Summary of common problems and solutions during the use of potting compound  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address