The difference between condensation type and addition type silicone sealant

Jul 18,2023

Jul 18,2023

Hanast

Hanast

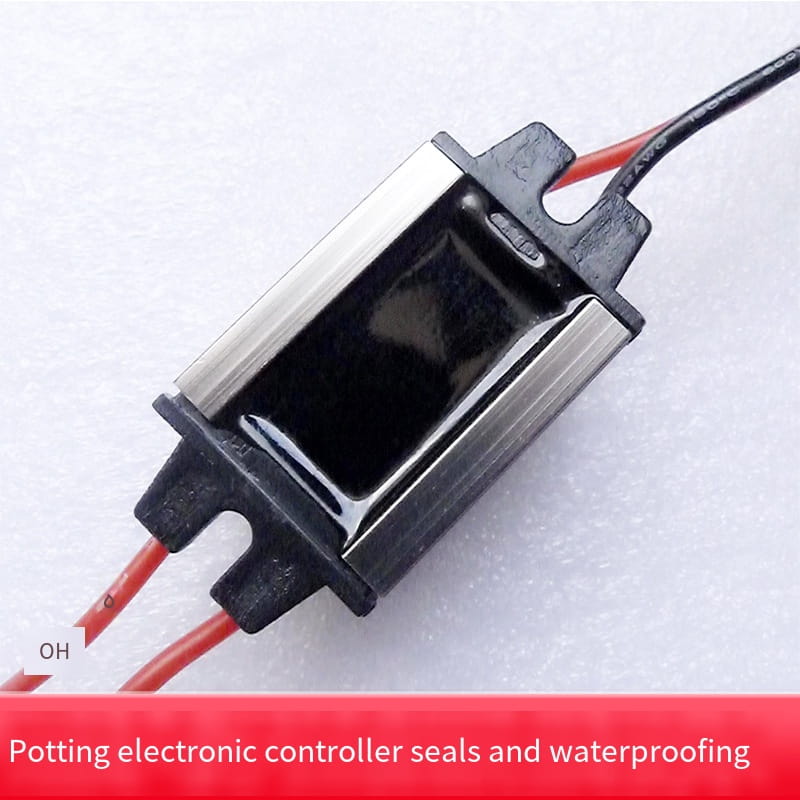

Organic Silicone potting adhesive has good flowability, simple and convenient operation, and can be used for molding applications such as pouring and injection. After curing, it has excellent electrical, protective, physical, and weather resistance characteristics. In terms of curing methods, there are two types of silicone sealant: addition molding and condensation type.

So what are the differences in application.

1、 Curing depth

After the two components of the silicone potting compounds are mixed evenly, the curing process is generally consistent. That is to say, the thickness of the potting adhesive is the same as the overall curing process. However, the condensation silicone potting compounds requires the participation of moisture in the air during the curing process, and the curing is carried out from the surface to the inside. The curing depth is related to the moisture and time. Therefore, in application, products with deeper or thicker filling or potting thickness are required, Generally, it is not suitable for condensation type potting adhesive.

2、 Heating applications

Improving the curing speed of silicone potting compounds can improve production efficiency. Therefore, many users increase the baking process, greatly accelerating the time of the next process. However, this process is only suitable for the use of additive silicone sealant, and the curing of condensation type sealant requires two key conditions, namely moisture and catalyst, which are not significantly related to temperature.

3、 Adhesive performance

When organic silicon sealant needs to have certain adhesive properties in the application process, it is preferred to choose condensed organic silicon sealant, which has good adhesive performance compared to most materials and will not have edge detachment. Compared with added organic silicon, it is slightly worse.

In addition to the above differences, for example, there is a stronger anti toxicity effect of condensed silicone sealant compared to additive molding; For applications related to food, choose additive molding without molecular volatilization.

Home

Home

What are the advantages of organosilicon potting compounds

What are the advantages of organosilicon potting compounds  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address