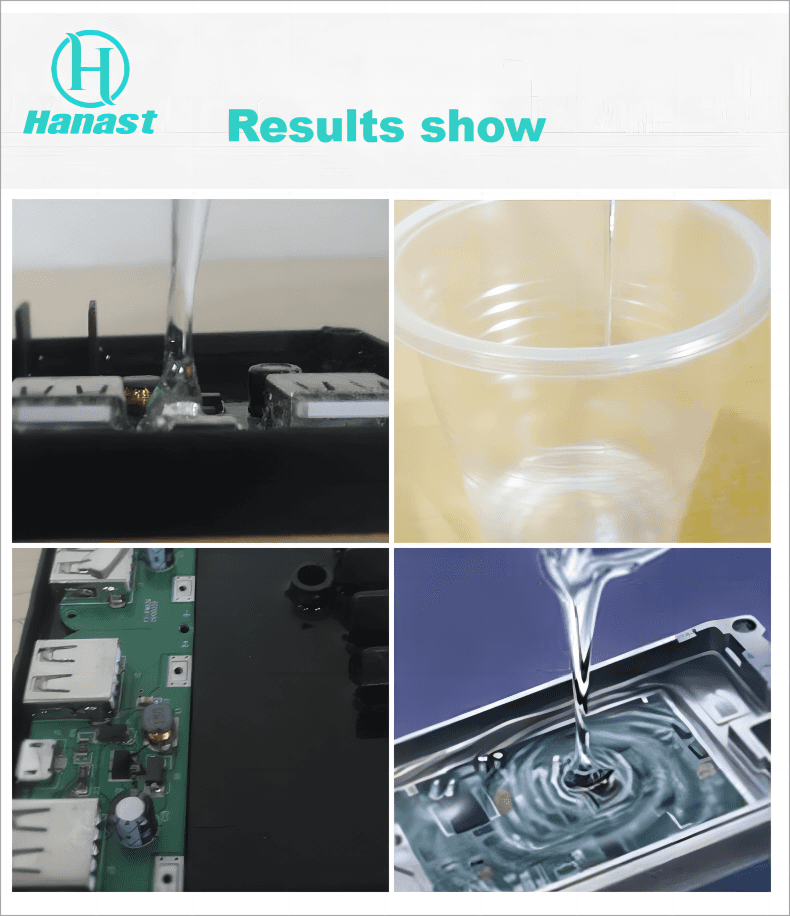

The difference in potting adhesive

Feb 26,2024

Feb 26,2024

Hanast

Hanast

The difference between polyurethane, silicone, and epoxy resin potting:

The main components of polyurethane (PU) potting adhesive are polyisocyanates and polyether polyols crosslinked and cured in the presence of a catalyst (triethylenediamine), forming a high polymer. Polyurethane adhesive has good bonding performance, insulation performance, and weather resistance. The hardness can be adjusted by adjusting the content of diisocyanates and polyether polyols and can be applied to the packaging of various electronic and electrical equipment.

Epoxy resin adhesive, like polyurethane adhesive, can be made into a two-component adhesive.

Epoxy resin potting adhesive is generally composed of bisphenol A epoxy resin, curing agent (amine or anhydride), reinforcing agent, and filler. It has a long curing time at room temperature and can be heated for curing. After curing, the adhesive strength is high and the hardness is generally high. It can be made into a transparent sealing adhesive, which is used for packaging electrical modules and diodes. For two-component sealing adhesive, the usage method is the same, ingredients mixing vacuum sealing. Two component sealing equipment can be used to simplify the entire operation process, while also saving operation time and reducing the waste of raw materials.

Polyurethane potting adhesive is a sealant developed for the long-term protection of precision circuit controllers and components in the electronic industry. It has excellent electrical insulation and is particularly suitable for sealing electronic circuit boards and components used in harsh environments such as humidity, vibration, and corrosive environments. Suitable for sealing various electronic components, microcomputer control boards, etc., such as washing machine control boards, pulse igniters, electric bicycle drive controllers, etc.

Polyurethane potting adhesive, also known as PU potting adhesive, overcomes the drawbacks of commonly used epoxy resin brittleness and low strength and poor adhesion of organic silicone resin. It has excellent water resistance, heat resistance, cold resistance, UV resistance, acid, and alkali resistance, high and low temperature impact resistance, moisture resistance, environmental protection, and high cost-effectiveness. It is an ideal sealing and protection material for electronic components. Comprehensively meet certifications such as V0 flame retardant rating (UL) and environmental protection certification (SGS).

Especially targeting the leakage problem of lithium-ion batteries, polyurethane sealing adhesive exhibits strong resistance to electrolyte corrosion.

Home

Home

What material is used for bonding silicone products?

What material is used for bonding silicone products?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address