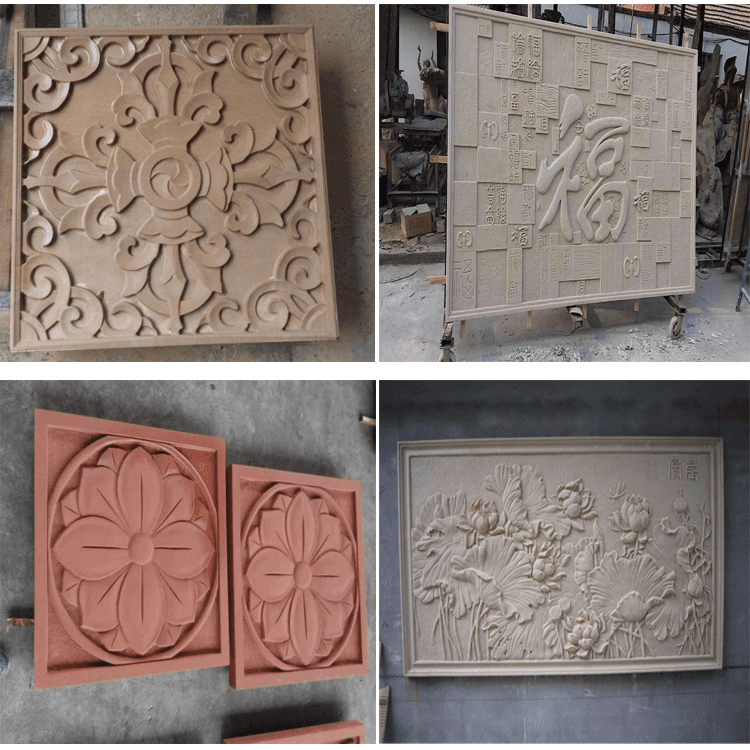

Usage of silicone for brick carving molds

Feb 23,2024

Feb 23,2024

Hanast

Hanast

The method of using silicone for brick carving molds requires us to first distinguish between brick carving molds. liquid rubber for molds Generally, we choose whether to use brush mold or injection mold technology based on whether the product is a flat or three-dimensional graphic.

Usually, brick carving molds with three-dimensional graphics are made using split film, because the silicone used in brick carving molds made with split film is relatively easy to peel off, and the cost of using silicone is also lower. However, there are also drawbacks. The disadvantage is that the production of split film brick carving molds is labor-intensive, usually taking more than ten hours to complete a mold, and the resulting product will have a split line, which affects the aesthetics. On the other hand, the most commonly used process for floor plans is injection molding. The silicone produced by injection molding is smoother without mold lines, and the labor cost is relatively low. It only takes about ten minutes to complete the operation and continue producing other brick carving molds. However, there are also drawbacks, such as consuming more silicone material for brick carving molds. There is no good or bad mold-making process, only suitable or unsuitable. Choose the appropriate process according to your production needs.

Regarding the operation of silicone for brick carving molds, it is relatively simple and only requires a few steps:

1. First step

The treatment of the mold requires the application of a release agent, which can be soap water, detergent water, Vaseline, or oil-based release agents. The main purpose of applying a release agent is to make the product smoother and more beautiful and to prevent small parts of the silicone from sticking to the mold.

Step 2

According to the required amount of silicone for mold production, the amount of curing agent added is 2-3% of the weight of silicone.

Attention:

1. It is necessary to strictly follow the proportion ratio. Excessive curing agents can affect the performance of silicone gel and cause shrinkage

2. When mixing, electronic scales should be used, and do not use a measuring cup for mixing.

Step 3

The well-proportioned silicone gel needs to be stirred evenly

Attention: It is necessary to stir evenly to prevent local mixing of curing agents from affecting the curing effect

Step 4

The stirred silicone gel will be mixed with air and requires vacuuming and exhaust bubble treatment, depending on the power and time of the vacuum machine

Step 5

Make a mold by coating or pouring the vacuum-filled silicone gel

Notes:

1. The amount of curing agent should be determined by temperature and decrease when the temperature is high. Excessive use of curing agents can cause the mold to become hard and brittle; Using too little curing agent will prolong the operation time.

2. Complete the above operations within the specified time range according to different process requirements during the operation process. (The operation time refers to the period from the mixing of silicone gel and curing agent to the cessation of silicone gel flow, which we call the operation time)

The general brushing operation time is 10-20 minutes, and the pouring time is 30-50 minutes. We can adjust the operation time according to your process requirements.

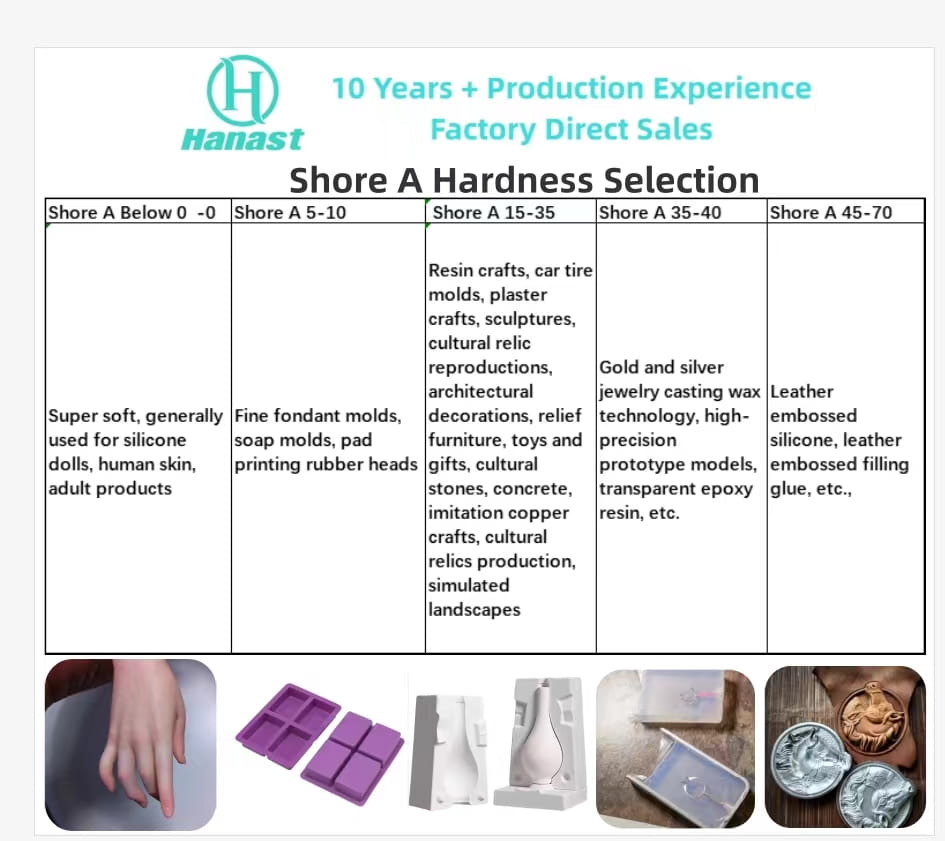

3. Depending on the size of the product, we can choose the hardness of silicone gel from 0 to 60 hardness, and we can produce all of them

4. For your mold to achieve optimal performance, please store the mold for at least 24 hours before use.

Home

Home

Example of silicone mold operation method

Example of silicone mold operation method  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address