What are the differences in silicone products with different hardness molds

Jul 15,2023

Jul 15,2023

Hanast

Hanast

In the silicone product industry, this problem also exists. How to distinguish the hardness and softness of silicone materials has become a problem for many consumers. In the design and development process of many products, it is impossible to predict how many soft and hard materials are needed to achieve functionality.

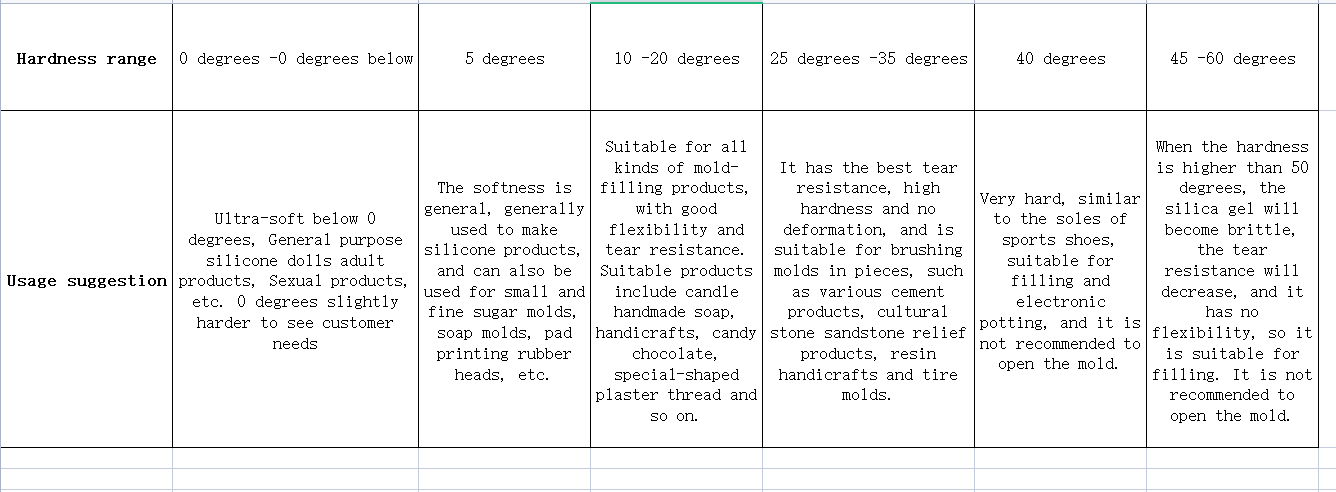

Therefore, how to choose the hardness and softness of mold silicone products

For silicone materials, the hardness determines whether the assembly function of the main product can be achieved and whether the buffering and shock absorption effect can be achieved. Currently, the hardness of silicone products used as molds in different industries typically ranges from 20 ° to 80 °. However, with the development and progress of materials in recent years, it can now reach 90 °, Under normal circumstances, the tolerance range for hardness is ± 5 °, and manufacturers of fine-grained raw materials can also adjust it to within ± 2 °. liquid silicone rubber for food grade For some products, the accuracy of hardness mainly determines the functionality of the product.

liquid silicone rubber for jewelry mold

For high hardness mold silicone products, the hardness of the product becomes more brittle, and the tearing resistance increases. Self splitting mold lines and burrs are prone to brittleness, so structure is one of the most critical issues. If the structure of the product is complex, even if there are inverted or right angle products that are not used properly after processing, it is easy to cause damage. Therefore, the higher the hardness, the simpler the product structure, The production yield and service life of overly complex products will be lower.

For low hardness mold silicone products, there is the opposite principle. The structure of products with lower hardness can be more complex and convenient for production and processing, with better elongation and resilience. However, the same tearing resistance may cause fracture during the stretching process, which is also related to the raw materials. liquid silicone molds However, low hardness products are prone to softening and unfamiliarity during the processing of silicone product manufacturers, During normal use, stress can also cause fractures due to oblique or right angles.

Mold silicone products with different hardness have different functional effects, and the difference in hardness and softness is mainly used as the functional effect of the product. Usually, the best functional effect can be achieved when the hardness is between 30 ° and 70 °. If the hardness is low or high, it will make some products difficult to process, increase the cost and production efficiency of the product.

Home

Home

What are the requirements for potting compound for switching power supply

What are the requirements for potting compound for switching power supply  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address