What are the requirements for potting compound for switching power supply

Jul 17,2023

Jul 17,2023

Hanast

Hanast

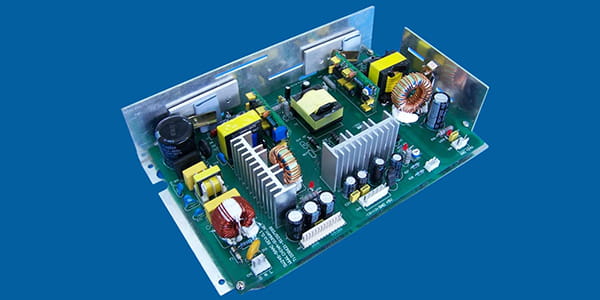

Switching power supply, as a power converter, plays a crucial role in the use of modern electronic devices. In the design of switching power supplies, the use of potting adhesive not only plays a role in curing and bonding, but also prevents the invasion of moisture and dust, improving the sealing and stability of the entire device. Therefore, selecting the right potting compound for the switching power supply is crucial for its working effect and lifespan.

So what are the requirements for potting compound for switching power supplies.

The first requirement is the hardness of the potting silicone. In the voltage control circuit of switching power supply, some components with high hardness requirements, such as oscillators, transformers, inductors, etc., will be used. If the hardness of the sealing adhesive is too high, it will reduce the oscillation frequency of these components, thereby affecting the output voltage and stability of the power supply. Therefore, the hardness of the sealing adhesive should be moderate, usually between 40-60A.

Secondly, there are temperature performance requirements for the potting silicone. Switching power supplies generate significant heat during use, therefore, the temperature tolerance requirements for potting adhesives are relatively high. Generally, the sealing adhesive should be able to withstand high and low temperature alternating effects within the range of -40 ℃ to+125 ℃ to ensure that the power supply can work normally in various environments.

In addition, there are requirements for the compression elasticity, bonding strength, and protective performance of the sealing adhesive. For example, the bonding strength of the potting silicone needs to reach a certain level to ensure that the components will not loosen or fall off under external forces such as vibration and impact. The waterproof, flame-retardant, and environmentally friendly properties of the potting adhesive also need to meet certain requirements to prevent damage to components caused by pollutants, moisture, oxygen, and other factors.

In short, potting adhesive plays a significant role in the design of switching power supplies, and its performance and quality requirements are correspondingly high. Only by selecting the appropriate sealing adhesive and strictly controlling the quality during the production process can the stability and long-term reliability of the switching power supply be guaranteed, providing guarantee for the continuous development and application of modern electronic equipment. If you don't know how to choose, you can consult Schneider. We have professional engineers to provide you with one-on-one selection guidance and adhesive solutions.

Home

Home

What is the reason for the unevenness of the potting adhesive after curing, Does it have an impact on performance

What is the reason for the unevenness of the potting adhesive after curing, Does it have an impact on performance  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address