What is the reason for the unevenness of the potting adhesive after curing, Does it have an impact on performance

Jul 17,2023

Jul 17,2023

Hanast

Hanast

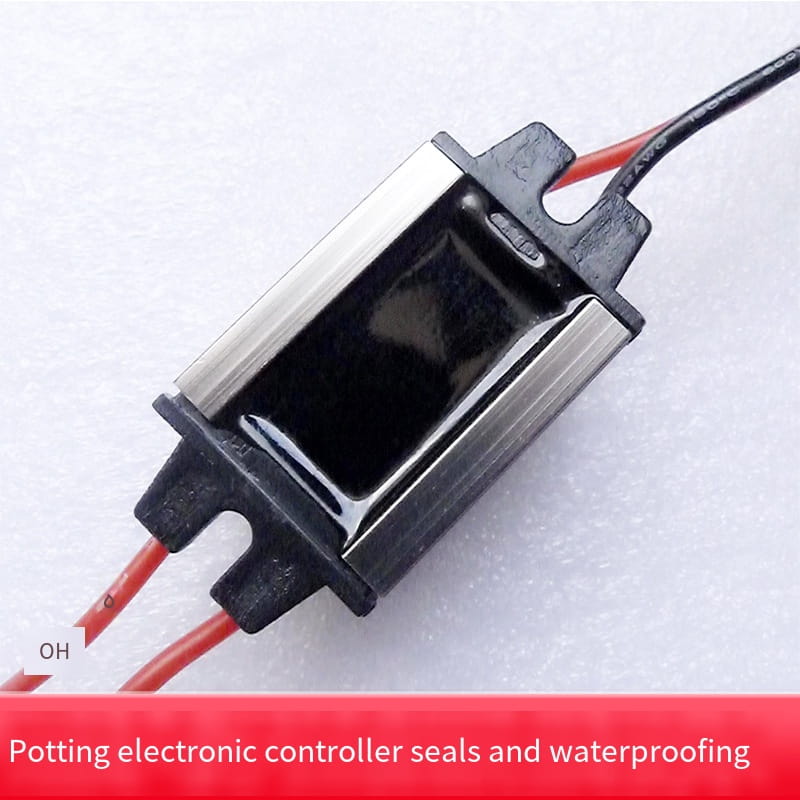

silicone potting compounds has fluidity during the injection process, and the surface is very smooth after curing, with a smooth film layer. However, some users have found that the surface of the sealing adhesive is uneven after curing.

What is the reason for this phenomenon and can it affect the properties of the silicone potting compounds.

Why is the unevenness of the silicone potting compounds after curing?

The reason why the silicone potting compounds exhibits unevenness after curing is related to the temperature of the construction environment. During the construction process, if the environmental temperature is too high and the adhesive liquid has not yet completed automatic flow and leveling, a curing reaction occurs. At this point, the phenomenon of uneven gel after curing will occur.

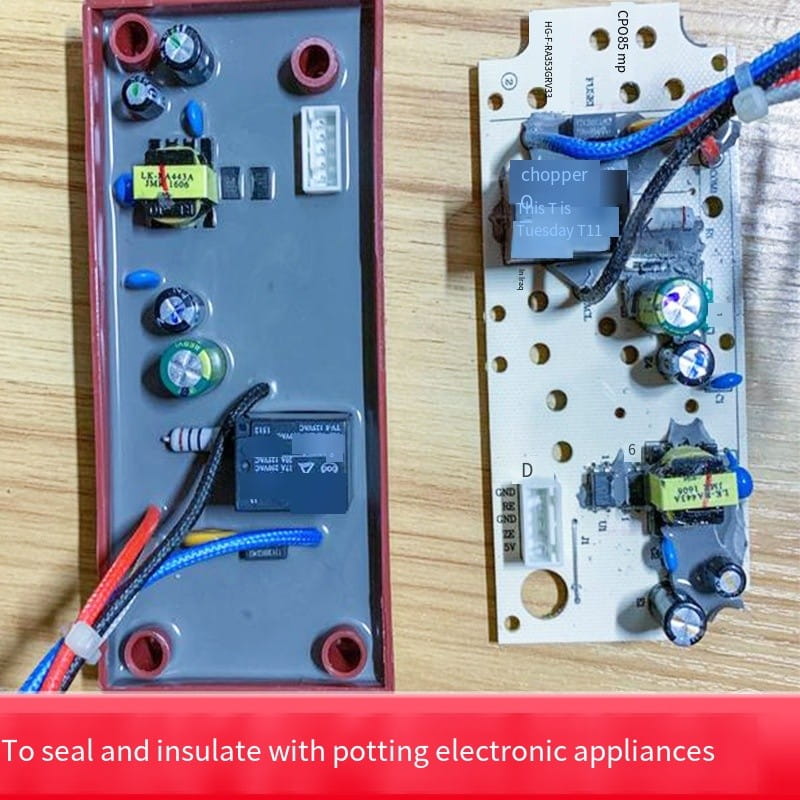

2. There is residual impurities in the mixing cup or mixer, and the substrate has not been cleaned in a timely manner. After mixing the adhesive, it is poured onto the surface of the substrate, and after curing, there will be uneven phenomena.

If the sealing adhesive wants to avoid unevenness after curing, in addition to paying attention to the temperature of the construction environment, it is also necessary to regularly maintain the construction equipment and rinse it clean in a timely manner after use. The surface of the construction substrate needs to be free of oil and dust.

Does the unevenness of the potting adhesive after curing have a significant impact on its performance?

The unevenness of the gel after curing has a significant impact on the performance of the sealing adhesive. The waterproof and moisture-proof properties of the thin gel position are poor, and other properties will also decrease accordingly. The position where the gel is slightly thick makes it difficult to detect components with a needle, and it is difficult to locate components after they fail.

After solidification, the unevenness of the gel can also lead to unstable electrical performance. During operation, even if the components are tightened with screws, the thick position of the adhesive layer will still slightly tilt, and long-term use will increase the probability of electrical failure.

In addition, the phenomenon of uneven surface after curing of the potting adhesive is closely related to the manufacturing process and purity of the potting adhesive itself. Therefore, Schneider recommends that customers have a thorough understanding of the product before selecting a high-quality potting adhesive manufacturer during the initial selection process. Having strength, stable quality, professional technology, complete solutions, and rich case studies can all be used as reference factors. As the leader of the 10-year adhesive solution, HANAST solemnly promises to adhere to the policy of answering all questions and actions when encountering adhesive problems.

Home

Home

Common Phenomena and Solutions of

Common Phenomena and Solutions of  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address