Difference between thermal conductive silica gel and thermal conductive silicone grease

Dec 13,2022

Dec 13,2022

Hanast

Hanast

1. Thermal conductive silicone grease: a thermal conductive organic silicone grease like compound made from organic silicone as the main raw material and added with materials with excellent heat resistance and thermal conductivity.

2. Thermal conductive silica gel: It is a thermal conductive compound.

Thermal conductive silica gel is a kind of one component dealcoholized room temperature curing silicone rubber, which has cooling and bonding effects on electronic devices. It can be cured into elastomer with high hardness in a short time. After curing, it is closely fitted with its contact surface to reduce the thermal resistance, which is conducive to the heat conduction of the heat source and its surrounding heat sink, main board, metal shell and shell. This series of products has the advantages of high thermal conductivity, good insulation and easy use. This product has good adhesion to copper, aluminum, stainless steel and other metals. The curing form is dealcoholized and does not corrode metal and nonmetal surfaces.

The thermal conductive silicone grease, also known as silicone paste, is a kind of grease, which has no bonding property and will not dry. It is produced with a special formula and is compounded with organosiloxane using metal oxides with good thermal conductivity and insulation. The product has thermal conductivity, good electrical insulation, wide use temperature (working temperature - 50 ℃~250 ℃), good use stability, low consistency and good construction performance. It is non-toxic, non corrosive, tasteless, dry and insoluble.

Different characteristics

1. Thermal conductive silicone grease: It has high thermal conductivity, good thermal conductivity, good electrical insulation (only for insulating thermal conductive silicone grease), wide service temperature, good service stability, low consistency and good construction performance.

2. Thermal conductive silica gel: It emits low molecules through condensation reaction of water in the air to cause cross-linking and curing, and vulcanizes into high-performance elastomer. It has cold and heat resistance, aging resistance and electrical insulation performance. It has excellent moisture-proof, anti-seismic, corona resistant, anti leakage and chemical resistance.

3、 Different uses

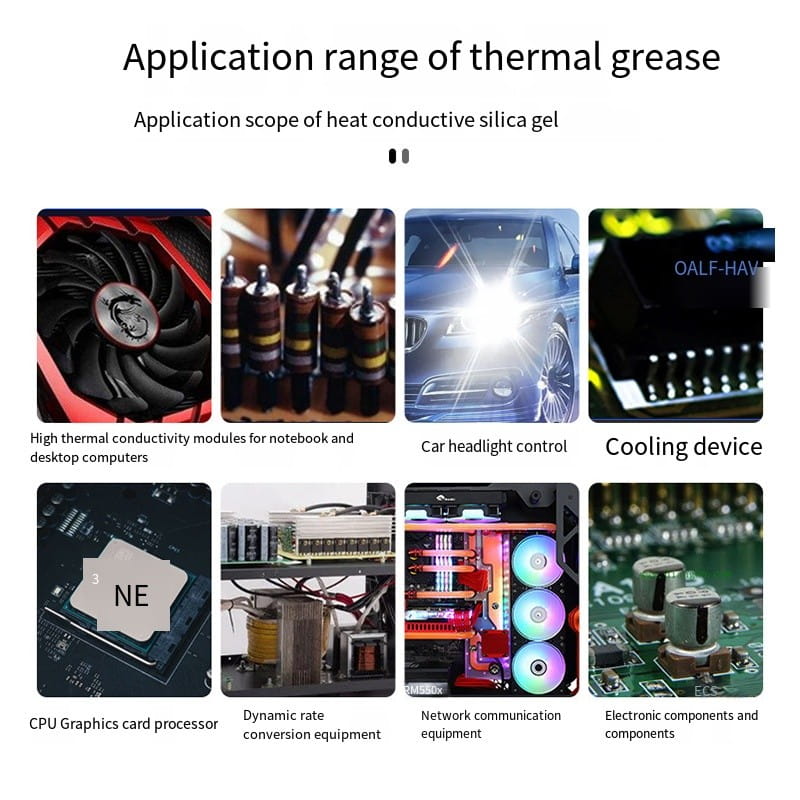

1. Heat conductive silicone grease: used for heat conduction and heat dissipation of power amplifiers, transistors, electronic tubes, CPUs and other electronic components, so as to ensure the stability of the electrical performance of electronic instruments and meters.

2. Thermal conductive silica gel: it is widely applied to the contact surface between the heating element (power tube, silicon controlled rectifier, electric heating stack, etc.) in various electronic products and electrical equipment and the cooling facilities (radiator, radiator, shell, etc.), playing the role of heat transfer medium and moisture-proof, dust-proof, anti-corrosion, shockproof, etc.

Home

Home

Precautions for using silicone glue

Precautions for using silicone glue  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address