How to choose the appropriate hardness for liquid silicone

Mar 08,2024

Mar 08,2024

Hanast

Hanast

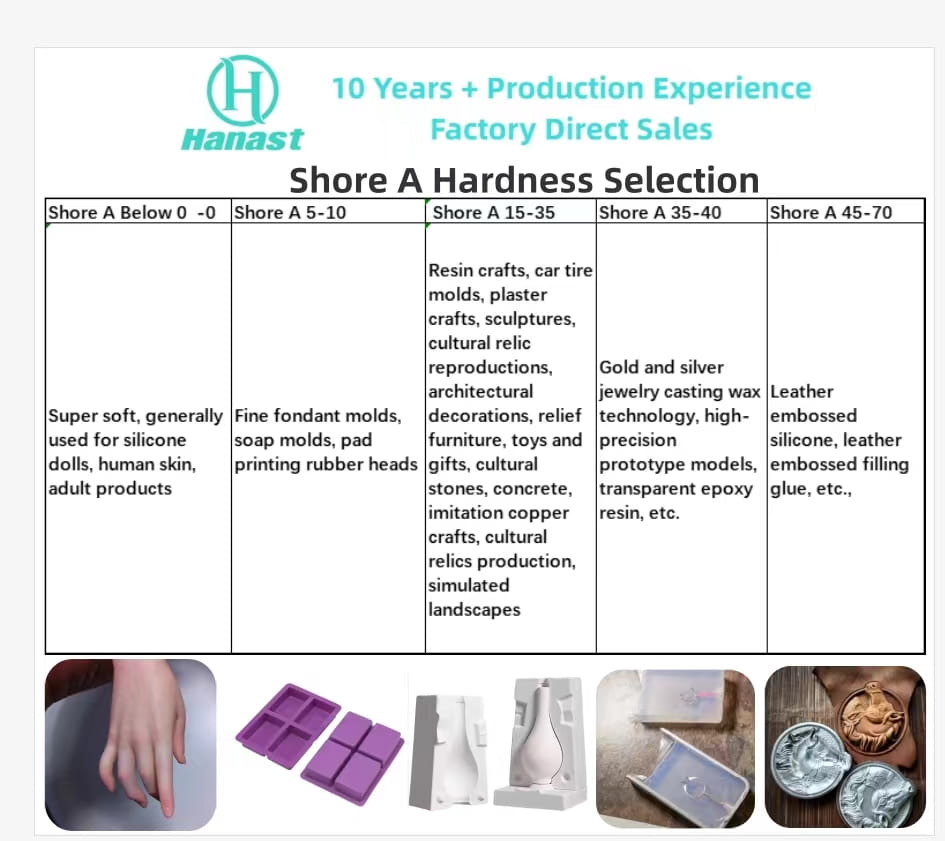

When the hardness of the mold silicone is below 10 hardness, the silicone tear strength is low, the elongation is high, and the silicone product is prone to deformation; When the hardness is higher than 50 hardness, the tear strength deteriorates, and silicone products become brittle and prone to breakage or breakage. When the hardness of silicone gel is generally between 20-40, tear strength, elongation, and other factors are optimal. In addition, the lower the viscosity (better fluidity), the more favorable it is for vacuum exhaust bubbles, but at the same time, the tear resistance will also decrease and the number of demolding times will be reduced.

The 0 hardness mold silicone is an ultra-soft silicone, which is an additive colorless transparent liquid with excellent electrical properties and chemical stability. It is resistant to water, ozone, climate aging, corrosion, physiological inertness, low linear shrinkage, and easy operation. Commonly used for chest pads, shoulder pads, etc., silicone products made of it are washable, bubble-free, and will not shatter.

Silicone with a hardness of 5-10 hardness is a soft silicone material with low hardness, good fluidity, easy pouring, and no corrosiveness. It is very suitable for soap handicrafts with delicate and soft patterns. The soap molds made do not emit oil, deform, and have a smooth and bright surface.

Silicone with a hardness of 10-25 degrees is recommended for products with sizes between 10-20 centimeters. It is suitable for replicating product models with very fine patterns and performing injection molding operations. This mold opening method is relatively easy to de-mold and will not damage the products inside the silicone mold. It can be used for making candles, replicating various handicraft models, and can also be used for clothing label embossing (adhesive planting), etc. Candle silicone can be selected from two types: condensation type and addition type. Crafted silicone candles can be quickly ignited and continue to burn normally until the candle is burned out, without oil leakage during the combustion process

It is recommended to use silicone with a hardness of 25-30 hardness for products with dimensions between 30-50 centimeters, and it is suitable for selecting a brush mold opening method. Condensed silicone can be used for the production of silicone molds for gypsum, cement, concrete, rapid prototyping, GRC European components, large cement components, imitation marble, artificial cultural stones, and other materials; Adding transparent silicone can be used for injection molding, imitation diamond, jewelry model making, and more. The E608 model can be selected for shoe mold production.

It is recommended to use brush molds (split mold, three-dimensional mold, flat mold) for silicone with a hardness of 40-50 degrees, which is suitable for products with less precise patterns;

If the customer is making small products with very fine patterns, they need to use slightly softer silicone; If you are making larger products, you need to use silicone with a hardness of 32-35A ° C and higher.

Home

Home

Solution for Bubble Content in Flipped Silicone Products

Solution for Bubble Content in Flipped Silicone Products  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address