What are the characteristics of translucent liquid silicone rubber?

1) semi-transparent liquid silicone rubber is easy to operate, can be adjusted brush mold, film pouring process (thin, thick) .

2) the fluidity of semitransparent liquid silica gel is good and the foam is good.

Apr 22,2023

Apr 22,2023

How to bond RTV silicone rubber to plexiglass?

The surface of plexiglass is too smooth for bonding. You want to use sandpaper will be plexiglass need to bond parts polished into rough, so that can effectively increase the bond strength. There are many kinds of RTV silicone rubber, you do not choose mold rubber. Mold rubber for easy release, there are anti-adhesive components, no adhesion. You have to choose building silicone sealant or structural adhesive, this kind of adhesive inside a tackifier, bonding effect is good.

Apr 17,2023

Apr 17,2023

How to use single component RTV silicone adhesive correctly?

Usage of one-component RTV silica gel adhesive: usage of adhesive before bonding, the surface of the adhesive should be cleaned, and the higher working surface should be wiped clean with ethanol as cleaner, the bonding effect is better. Mainly depends on the role of trace moisture in the air and solidification. The adhesive layer should not be too thick (generally 1-2 mm thick) . It can not be used for surface bonding of large areas of objects. It can not be used for deep perfusion or structural bonding. It can be stored for one year under 30 °C.

Apr 17,2023

Apr 17,2023

As much heat-conducting silicone as possible?

The main function of the heat-conducting silicone grease on the CPU is to transfer the heat of the CPU to the radiator, so that the temperature of the CPU can be maintained at a stable operating level and the CPU can not be damaged due to poor heat dissipation, this greatly increases the life of the CPU. In addition, the more thermal silicone coating is not the better heat dissipation, but in the premise of ensuring that the gap filled as thin as possible, the more the coating is not beneficial, this will affect the thermal conductivity.

Apr 17,2023

Apr 17,2023

How often is the heat-conducting silicone replaced?

In fact, this situation varies from person to person, mainly depending on the use of the computer environment. If your use of the environment often overheated or bad use habits, you can consider half a year to replace once, by the way open with cleaning maintenance. If you use it well, under normal conditions of use, the heat-conducting silicone grease is usually replaced once a year.

Apr 17,2023

Apr 17,2023

What is the difference between RTV liquid silicone mold and plastic mold?

1. Plastic mold is mainly used for compression, extrusion, injection, blow molding and low-foaming molding of composite plastic mold. And it has a runner, before the production of plastic products, plastic raw materials need to be additional bake more than 2 hours, can be put into the mold production. So this will be a waste of time, but also more trouble. Plastic mold is mainly used in making large tools and biochemical tools, household appliances, instrumentation, construction equipment, automotive industry, daily hardware and many other fields. Mainly the production of plastic products mold.

Apr 17,2023

Apr 17,2023

How to accelerate the curing speed of RTV sealant?

The thicker the adhesive applied to the sealed area, the longer the curing time required. Therefore, reducing the amount of adhesive applied appropriately or using heating methods can improve the curing speed.

Apr 14,2023

Apr 14,2023

What are the advantages and disadvantages of organic RTV silicone adhesive after curing?

The main performance of organic RTV silicone adhesive is its excellent waterproof and temperature resistance properties, which maintain stable state and performance in low and high temperature environments.

Apr 14,2023

Apr 14,2023

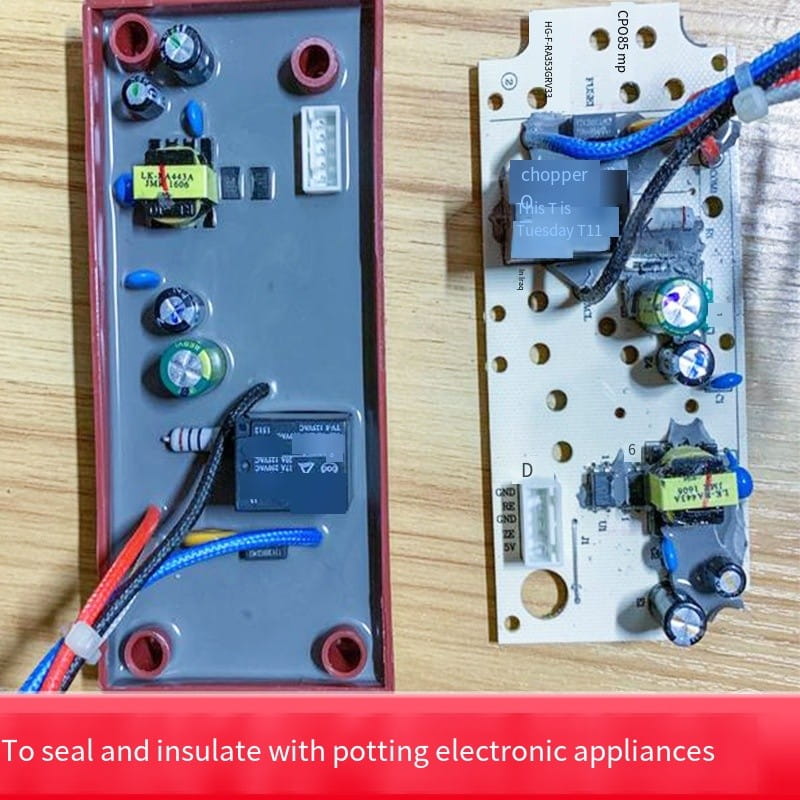

How to clean electronic potting adhesive?

1. After curing, epoxy resin adhesive is hard and relatively brittle, especially epoxy type epoxy adhesive, which is prone to breakage under external force. When removing the epoxy adhesive, we can take advantage of this characteristic of the epoxy adhesive. As long as we use external force to knock and break the epoxy adhesive, we can separate the items that have been bonded with the epoxy adhesive. However, this method is only suitable for items that can withstand external force strikes, If it is fragile items such as ceramics, this method cannot be used, and the epoxy adhesive after separation needs to be cleaned using other methods.

Apr 14,2023

Apr 14,2023

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address